11

– Fully unwind the flexible insulated hose.

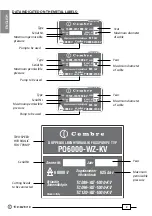

– Position the pump as far as possible from the cutting point and connect it to the flexible insulated

hose.

– Place the pump such that the flexible insulated hose can be laid “zigzag” on the ground.

This precaution is to compensate for shortening of the hose while the pump is operating.

– If for any reason the minimum 10m radius no entry zone cannot be established, other precautionary

measures must be taken (e.g. embankments or protection walls) to protect the operator from a

possible disturbance arc due to a short circuit.

– Should there be the danger of voltage gradients between cutting head and pump, the pump

can be connected to earth using the earth terminal and the specific cableso as to form an equi-

potential connection.

– Contact the electricity supply utility.

– Check that nobody enters the danger zone.

– Carry out the cutting operation by operating the pump pedal.

Position the foot in the centre of the pedal crank.

During operating of the pump, check pressure on the manometer.

– During the cutting operation there is a slow increase in pressure which can vary depending on

the type of cable.

– It is necessary to continue to use the pump until the maximum permissible over pressure

is reached and the safety valve is heard to click into action.

– Operate the oil discharge lever of the pump and keep it pressed for about 60 seconds so that the

blades of the cutting head can automatically return to the start position.

– Inform the electricity supply utility that the cutting operation has been carried out.

If they do not warn against any particular events, the cutting zone can be accessed.

– Access the cutting area and remove the cutting head from the cable using the support grip

provided.

?

?

?

ENGLISH