If your building is not insulated, you will have good combustion and better evacuation of the

steam. On the other hand, if it is well insulated, you should ensure that you have air inlets to

improve combustion and the pull of the chimneys.

INSTALLATION

1)

Remove the wheels under the evaporator.

2)

Remove the evaporator pans. Level the evaporator with the adjustable legs.

3)

When the evaporator is leveled (in length and width), tighten the nuts on the lower legs.

4)

Brick work

4.1 Place insulation boards against the interior walls of the evaporator. You can use

"Pyromix" brick cement to help hold them in place. The panels can be cut with an

exacto knife or a hand saw. Ceramic wool can replace the panels as needed. A dust

mask should be used when you insulate your evaporator. For superior insulation, it is

possible to create an air chamber by pressing a metal roof sheet against the stainless

steel sheet before installing the panels or the wool.

4.2 With heat resistant bricks, start by covering the bottom of the evaporator.

Subsequently, cover the walls. Start at the front bottom and gradually go up and

toward the rear. Brick cement must be applied in a thin layer behind and on each side

of the bricks to ensure the solidity of the installation and to close the gaps.

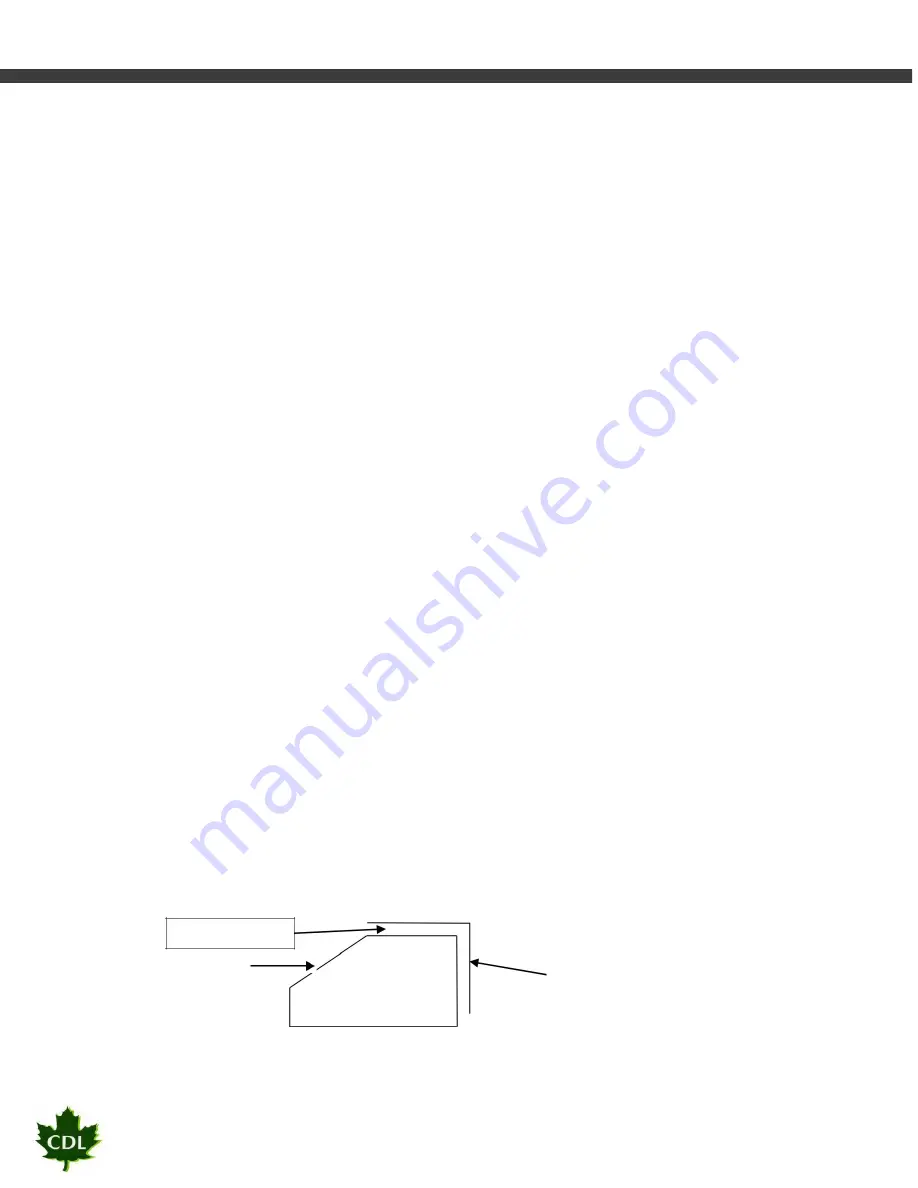

4.3 The last row of upper bricks should be bevelled in order to ensure that the heat of the

fire covers the largest possible area under the pans. (Image A). Do not force the bricks

under the steel angle above. In the heat, the bricks will work. If installed too tight, the

frame may bend. Leave a space of about ¼" between the last row of bricks and the

steel angle.

4.4 Insert in this space ceramic wool scraps without putting too much pressure to prevent

the heat from reaching the steel angle.

Ceramic wool

Brick

Image A

Top steel

angle

Les Équipements d’Érablière CDL Inc.

4