3. Examine Sleeves for scoring or etching and replace.

Immerse sleeves (D) in oil and carefully twist and

push sleeve onto rod with machined counter bore

end first (E).

4. Install Seal Retainers. If Wicks are used, replace Wicks,

thoroughly saturate with oil, place in Seal Retainer and

install retainer.

5. Place Inlet Manifold on pair of clearance blocks with

crankcase side down and drive out old seals.

6. Invert Inlet Manifold with crankcase side up and install

new Seals. Lubricate O.D. of Seal and install

Prrrrm-A-Lube Seal with garter spring down. If using

blue dot seal, install blue dot seal facing up.

NOTE: When using alternate materials, the fit of the

special materials may be snug and require gently

driving the LPS into position with a cylinder of the

same diameter to assure a square seating and no

damage to the LPS.

NOTE: 25FR and 60FR do not have Prrrrm-A-Lube

option. Install with spring down.

7. Slip lubricated Seal inserters onto Piston Rod ends,

position Inlet Manifold onto pump and remove Seal

inserters. Some models secure Inlet Manifold to

crankcase. Replace fasteners and torque per chart.

8. Reassemble Piston Assemblies and Discharge

Manifold as described.

9. Replace original quantity of Shims on each stud before

replacing Discharge Manifold. Refer to Tech Bulletin 017.

■

Hi-Temp Models

On the Model 2520C series, the Seal with the lip, the

adapter and the Seal with grease pocket can be driven

from the Inlet Manifold.

To install a new Seal assembly, place Manifold on work

surface with crankcase side up. Install new seal with lip

in chamber with garter spring down. Next examine

O-Ring and Adapter and replace either if worn. Lubricate

outer surface of Adapter and install new O-Ring. Press

Adapter into chamber, smaller diameter end first. Next

install grease pocket seal with garter spring down. Then

proceed with standard reassembly of pump.

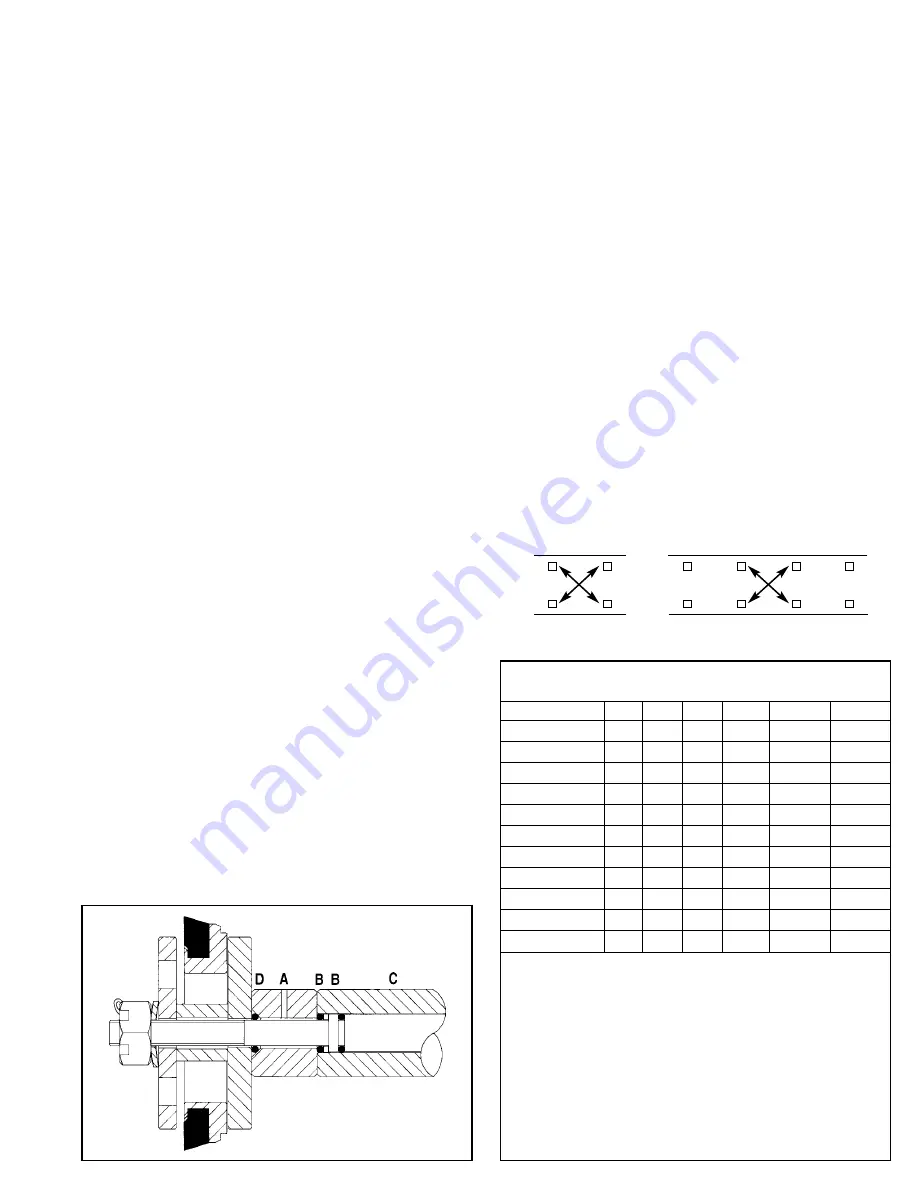

4 BOLT MFLD

8 BOLT MFLD

1

3

7

1

3

5

4

2

6

4

2

8

The hi-temp models also have a special vented Inlet

Valve Spacer (A) Following the installation of the Piston

Rod O-Rings (B) and Sleeve (C), slip this vented Spacer

onto the Rod with the tapered end forward. Then install

O-Ring (D) in the tapered groove and proceed with

standard Piston Assembly.

SERVICING CRANKCASE SECTION

1. While Inlet Manifold, Sleeves and Seal Retainers are

removed, examine Crankcase Seals for wear.

2. Check oil for proper level and for evidence of water in

the oil. Change crankcase oil on a reqular schedule.

See Preventative Maintenance Check-List.

3. Rotate Crankshaft by hand to feel for smooth bearing

movement.

4. Examine Crankshaft Oil Seal externally for drying,

cracking or leaking.

5. Consult your local CAT PUMPS supplier if Crankcase

Service is required.

TORQUE SEQUENCE

PREVENTATIVE MAINTENANCE CHECK-LIST

Check

Daily Weekly 50 hrs. 500 hrs.* 1500 hrs.** 3000 hrs.**

Clean Filters

x

Oil Level/Quality

x

Oil Leaks

x

Water Leaks

x

Belts, Pulley

x

Plumbing

x

Initial Oil Change

x

Oil Change

x

Seal Change

x

Valve Change

x

Accessories

x

* If other than CAT PUMPS special multi-viscosity ISO68 oil is used,

change cycle should be every 300 hours.

** Each system’s maintenance cycle will be exclusive. If system

performance decreases, check immediately. If no wear at 1500

hours, check again at 2000 hours and each 500 hours until wear is

observed. Valves typically require changing every other seal change.

Duty cycle, temperature, quality of pumped liquid and inlet feed

conditions all effect the life of pump wear parts and service cycle.

** Remember to service the regulator/unloader at each seal servicing

and check all system accessories and connections before resuming

operation.