16. Replace burner removal covers on respective sides of furnace.

17. Remove front blower door and reinstall so instructional labels

are rightside up.

NOTE:

On high airflow models (75,000 and 100,000 Btuh), the

front and rear blower doors must be interchanged so that the

instructional labels are rightside up on both sides of furnace. Move

blower door knob to new front blower door.

WIRE ALTERNATE LIMIT SWITCH

1. Disconnect wires from limit switch located on front center

panel and reconnect wires to alternate limit switch on right

front panel. (See right-hand view of Fig. 5.)

2. Replace control box cover.

Limit switch wires MUST be moved to the alternate limit

switch when reversing the furnace to ensure safe operation.

Failure to follow this warning may result in a hazardous

operating condition.

ELECTRICAL CONNECTIONS

See Fig. 10 for a wiring diagram showing the proper field 115- and

24-v wiring connections. Check all electrical connections (both

factory and field) for tightness. In all instances, wiring to be done

and any replacement wire shall conform with the temperature

limitation for Type T wire (63°F/35°C rise).

Step 1—115-v Wiring

Before proceeding with electrical connections, make certain that

voltage, frequency, and phase correspond to that specified on unit

rating plate. Also, check to be sure that service provided by utility

is sufficient to handle load imposed by this equipment. Refer to

rating plate or to Table 4 for equipment electrical specifications.

Do not connect aluminum wire between the disconnect switch

and the furnace. Use only copper wire.

Make all electrical connections in accordance with the National

Electric Code ANSI/NFPA 70-1996 and any local codes or

ordinances that might apply.

For Canadian installations, all electrical connections must be made

in accordance with CSA C22.1 Canadian Electrical Code, or

authorities having jurisdiction.

When replacing any original wiring, use only 105°C, AWG No. 16

copper wire.

Use a separate, fused branch electrical circuit containing a properly

sized fuse or HACR-type circuit breaker for this furnace. See

Table 4 for wire size and fuse specifications. A disconnecting

means must be located within sight of and readily accessible to the

furnace.

Table 4—Electrical Data

UNIT SIZE

VOLTS—

HERTZ—

PHASE

OPERATING

VOLTAGE RANGE

MAX

UNIT

AMPS

MIN

WIRE

SIZE

MAX WIRE

LENGTH†

(FT)

MAX FUSE‡ OR

HACR-TYPE

CIRCUIT BREAKER

AMPS

Max*

Min*

050-12

115—60—1

127

104

9.3

14

30

15

075-12

115—60—1

127

104

9.9

14

28

15

075-16

115—60—1

127

104

11.7

12

38

20

100-16

115—60—1

127

104

9.9

14

28

15

100-20

115—60—1

127

104

13.1

12

34

20

125-20

115—60—1

127

104

11.7

12

38

20

* Permissible limits of the voltage range at which the unit will operate satisfactorily.

† Length shown is as measured 1 way along wire path between unit and service panel for maximum 2 percent voltage drop.

‡ Time-delay fuse is recommended.

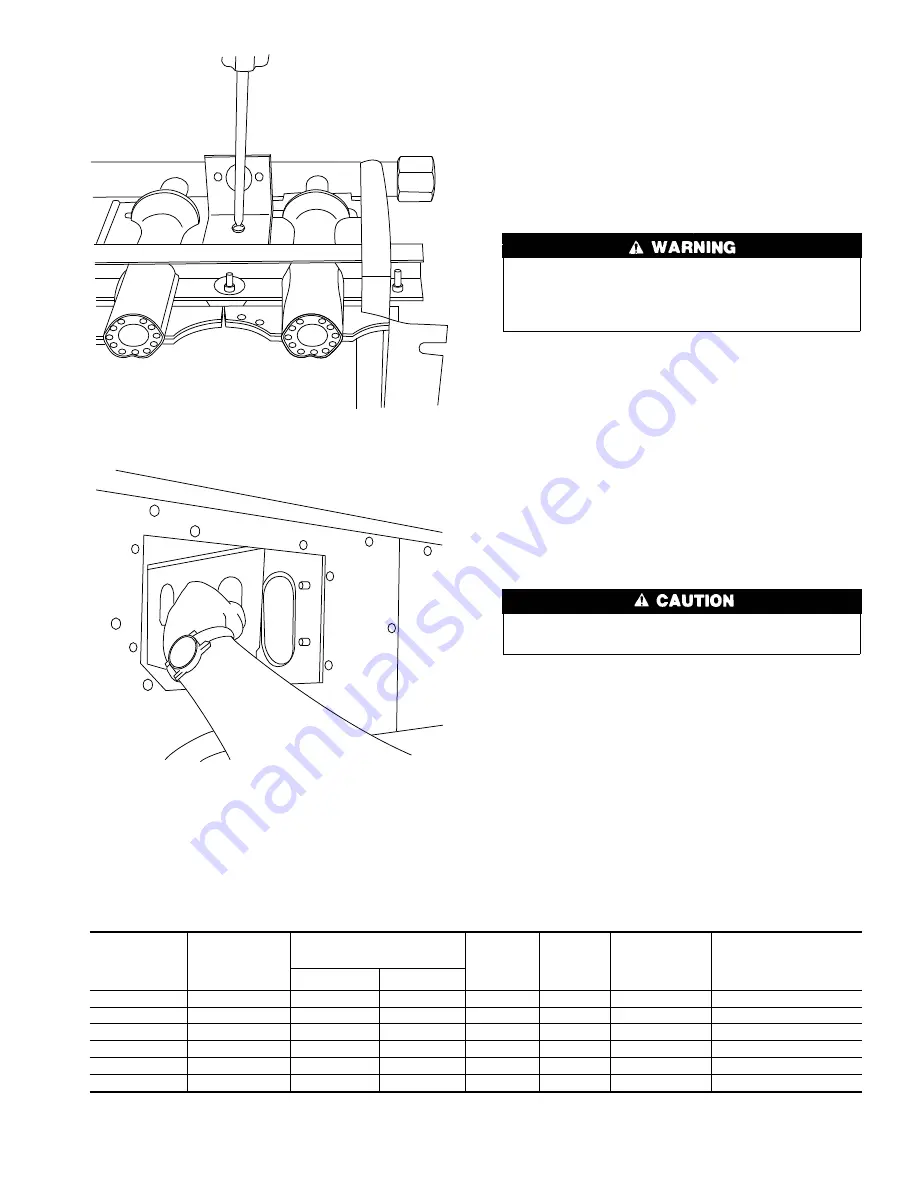

Fig. 8—Reattaching Rollout Switch Bracket

A96074

Fig. 9—Reversing Burner Opening Inlet Plate

A96075

9