15

For normal maintenance routines we recommend using 1 kg of

the concentrated product, diluted to 10%, to treat a coil surface

of 2 m

2

. This process can either be carried out with a

TOTALINE applicator gun (part No. TE01 WA 4000EE) or

using a high-pressure spray gun in the low-pressure position.

With pressurised cleaning methods care should be taken not to

damage the coil fins.

The spraying of the coil must be done:

- in the direction of the fins

- in the opposite direction of the air flow direction

- with a large diffuser (25-30

°

)

- at a distance of 300 mm.

The two cleaning products can be used for any of the following

coil finishes: Cu/Cu, Cu/Al, Cu/Al with Polual, Blygold and/or

Heresite protection.

It is not necessary to rinse the coil, as the products used are pH

neutral. To ensure that the coil is perfectly clean, we

recommend rinsing with a low water flow rate. The pH value

of the water used should be between 7 and 8.

WARNING: Never use pressurized water without a large

diffusor. Concentrated and/or rotating water jets are strictly

forbidden.

Correct and frequent cleaning (approximately every three

months) will prevent 2/3 of the corrosion problems.

WARNING: Never use pressurized air or water, as this will

damage the fins, and always clean them against the normal air

flow direction.

Fan motor replacement

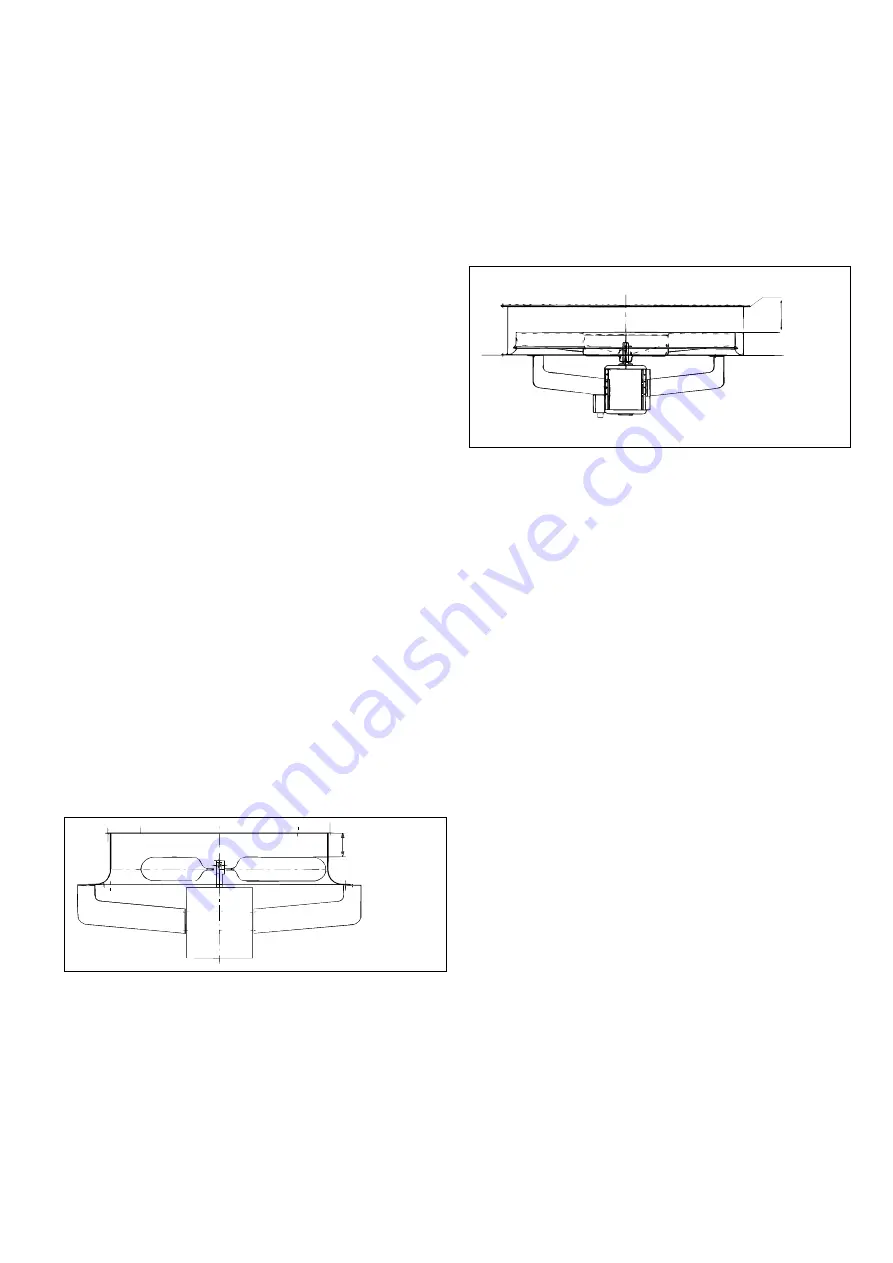

38AJ/AZ 008-012 units

Follow the safety considerations. Fan motors can be easily

removed through the top of the unit. Take care not to damage the

propeller. Label the wires to facilitate correct reassembly later.

38AJ/AZ 008-012 fan

Maximum

clearance

80 mm + mm

0

2

Maximum

clearance

170 + mm

0

2

38AJ/AZ 018-024 units

This presents no special problems. The work is done from

above the unit.

•

Remove the grille with its support air duct assembly.

•

Remove the fan shaft protection cap.

•

Pull the fan from the shaft using a FACOM U35, or

similar, hub puller.

•

Unscrew the fan motor fixing bolts.

WARNING: Remove only the lower bolts to prevent the

motor from falling.

Fan motor protection

All fan motors have thermal protection which will stop the

current flow when the fan motor temperature becomes too

high. The fans will restart automatically when the motor

temperature drops to a safe level. In addition all fan motors are

protected by one or several circuit breakers.

Refrigerant circuit

Liquid line service valve

This valve provides, in each circuit, a liquid refrigerant charging

port and, in conjunction with the compressor discharge line

valves, enables liquid refrigerant to be pumped to the high

pressure side of the system.

•

Withdraw the fan motor.

Installation is in the reverse order. Take care not to damage the

plastic components when installing the fan and position the fan

to maintain a clearance of 170 + 0/2 mm between the upper

edge of the fan and the upper edge of the volute. The tightening

torque on the fan motor support fixing screws must be 9 Nm.

CAUTION: On unit sizes 38AJ/AZ 014-074 the fan rotation is

counter clockwise, viewed from above.

38AJ/AZ 014-074 fan