2

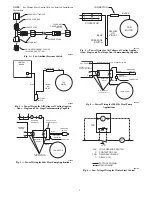

INSTALLATION

The pressure switch is mounted inside the outdoor unit cabinet by

using adapter tube supplied. The adapter tee is mounted to liquid

service valve and tube is either routed through one of the knockout

holes in unit cabinet (vertical discharge product) or through one of

the service valve holes in unit cabinet (horizontal discharge

product). From inside cabinet, the flare nut is attached to extender

tube. (See Fig. 1.) The pressure switch is wired in series with black

or common fan lead.

WIRING FOR ALL VOLTAGES OF COOLING UNITS

A. Single

−

And Two

−

Stage Non

−

Communicating Capable

For all voltages of cooling units, refer to Fig. 2 and wire

low

−

ambient pressure switch as follows:

1. Disconnect black fan lead from contactor and connect this

lead to yellow or violet wire from low

−

ambient pressure

switch using connector supplied.

NOTE

: To ensure electrical isolation and strain relief, it is

recommended to wrap connector with UL approved electrical tape

overlapping the wires on each side by a minimum of 1 inch.

2. Connect remaining blue wire from low

−

ambient pressure

switch to contactor terminal from which black fan lead was

removed.

B. Single

−

And Two

−

Stage Communicating Capable

For all stages of cooling units, refer to Fig. 3 and use

Low

−

Ambient Pressure Switch as follows:

1. Disconnect black fan lead from control board and connect it

it to yellow or violet wire from low ambient pressure switch

connector supplied.

NOTE

: To ensure electrical isolation and strain relief, it is

recommended to wrap connector with UL approved electrical tape

overlapping the wires on each side by a minimum of 1 inch.

2. Connect blue wire from low

−

ambient pressure switch to

control board terminal from black fan lead was removed.

WIRING FOR HEAT PUMPS

Heat pumps require a normally closed Isolation Relay (Part No.

KHAIR0201AAA or equivalent) with the 24v coil connected to

the C and O terminals of defrost board or control board.

A 208/230v Applications

For 208/230v heat pump applications, refer to Fig. 4 and wire

low

−

ambient pressure switch as follows:

1. Remove black lead of outdoor fan motor connected to de-

frost board OF2 or control board ODF depending on type

of unit.

2. Install piggyback female terminal on violet wire harness

(provided in isolation relay kit) to tab 1 of isolation relay.

Connect non

−

piggyback female termination of same violet

wire to one side of provided connector. Connect the female

termination of violet (or yellow) lead of low ambient pres-

sure switch to the other side of the provided connector.

Connect the female termination of the black fan motor lead

to the male piggy back terminal located at tab 1 of relay.

NOTE

: To ensure electrical isolation and strain relief it is

recommended to wrap connector with UL approved electrical tape

overlapping the wires on each side by a minimum of 1”.

3. Install piggyback female terminal on black wire harness

(provided in isolation relay kit) to tab 2 of relay. Connect

non

−

piggyback female termination of same black wire to

OF2 on defrost board or ODF on control board. Connect

the female termination of blue lead of low ambient pressure

switch to the male piggy back terminal located at tab 2 of

relay.

4. Install orange wire (provided in isolation relay kit) to one

side of the relay coil. Connect the other side to the O wire

coming from defrost board or control board.

5. Install black wire (provided in isolation relay kit) to oppos-

ite side of the relay coil. Connect the other side to the C

wire coming from defrost board or control board.

6. Reinstall control box cover and reconnect power to unit.

B. 460v Applications

For 460v heat pump applications, refer to Fig. 5 and wire

low

−

ambient pressure switch as follows:

1. Remove black lead of outdoor fan motor connected to out-

door fan relay terminal 3.

2. Install piggyback female terminal on violet wire harness

(provided in isolation relay kit) to tab 1 of isolation relay.

Connect non

−

piggyback female termination of same violet

wire to one side of provided connector. Connect the female

termination of violet (or yellow) lead of low ambient pres-

sure switch to the other side of the provided connector.

Connect the female termination of the black fan motor lead

to the male piggy back terminal located at tab 1 of relay.

NOTE

: To ensure electrical isolation and strain relief it is

recommended to wrap connector with UL approved electrical tape

overlapping the wires on each side by a minimum of 1” (25.4 mm).

3. Install piggyback female terminal on black wire harness

(provided in isolation relay kit) to tab 2 of relay. Connect

non

−

piggyback female termination of same black wire to

outdoor fan relay terminal 3. Connect the female termina-

tion of blue lead of low ambient pressure switch to the male

piggy back terminal located at tab 2 of relay.

4. Install orange wire (provided in isolation relay kit) to one

side of the relay coil. Connect the other side to the O wire

coming from defrost board or control board.

5. Install black wire (provided in isolation relay kit) to oppos-

ite side of the relay coil. Connect the other side to the C

wire coming from defrost board or control board.

6. Reinstall control box cover and reconnect power to unit.

REQUIRED CHANGES FOR COOLING UNITS AND HEAT

PUMP UNITS

1. Crankcase heaters are required on all applications where

low

−

ambient controls are used.

2. Start capacitor and relay (hard start) kits are required on all

single

−

phase applications where low

−

ambient controls are

used.

3. Evaporator freeze thermostat KAAFT0101AAA is required

on all applications where low

−

ambient controls are used.

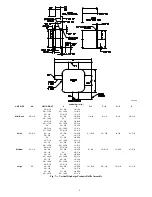

4. Wind baffles are recommended for temperatures below 0

_

F

(

−

17.80

_

C) or where there is substantial wind. For vertical

discharge outdoor products see Fig. 7 for dimensions of

Baffle Assembly. For horizontal discharge outdoor products

consult Product Data for Wind Baffle Kits.

NOTE

: When wind baffles are used on vertical discharge

products, raising the unit off of pad a minimum of 4 in. is required

to provide better airflow for moderate

−

and high

−

ambient

temperatures. Check presale literature for available support feet or

unit risers.

5. For cooling applications only, winter start control

KAAWS0101AAA must be used where low

−

pressure

switch tripping may be encountered. Winter start control

must be wired in parallel with low

−

pressure switch. This al-

lows a delay of 3 minutes before low

−

pressure switch be-