I N S T R U C T I O N S

For the installation and maintenance of D C 1 5 2 5 - D C 1 5 5 0

d e s u p e r h e a t e r s

IMI0049E.doc

Rev.0 20/08/14

20090 SEGRATE (MI)- via E.Fermi

EMAIL:

TEL.(02) 269912.1 - FAX.(02) 2692.2452

Page 10 of 16

version - 3” (DN 80), with maximum tube schedule of 160; for DC1550 50 m

3

/h version - 4” (DN 100) with

maximum tube schedule of 160.

The minimum length of tube required downstream varies according to application and is specified by

Carraro in the respective quote. This length without bends is necessary to prevent erosion caused by

drops of liquid deposited on the walls of the pipes, the valves and the fittings, and is normally a minimum

of 4, 6 m (a straight length of pipe is not generally necessary upstream). The distance that separates the

desuperheater from the temperature sensor is between 12 and 15 m, although the specific distance for

the application is generally specified in the quote.

Longer distances ensure complete evaporation of the liquid at lower process gas speeds. The

temperature sensor must be located in the top half of the pipe. Avoid fitting branches of the vapour pipe

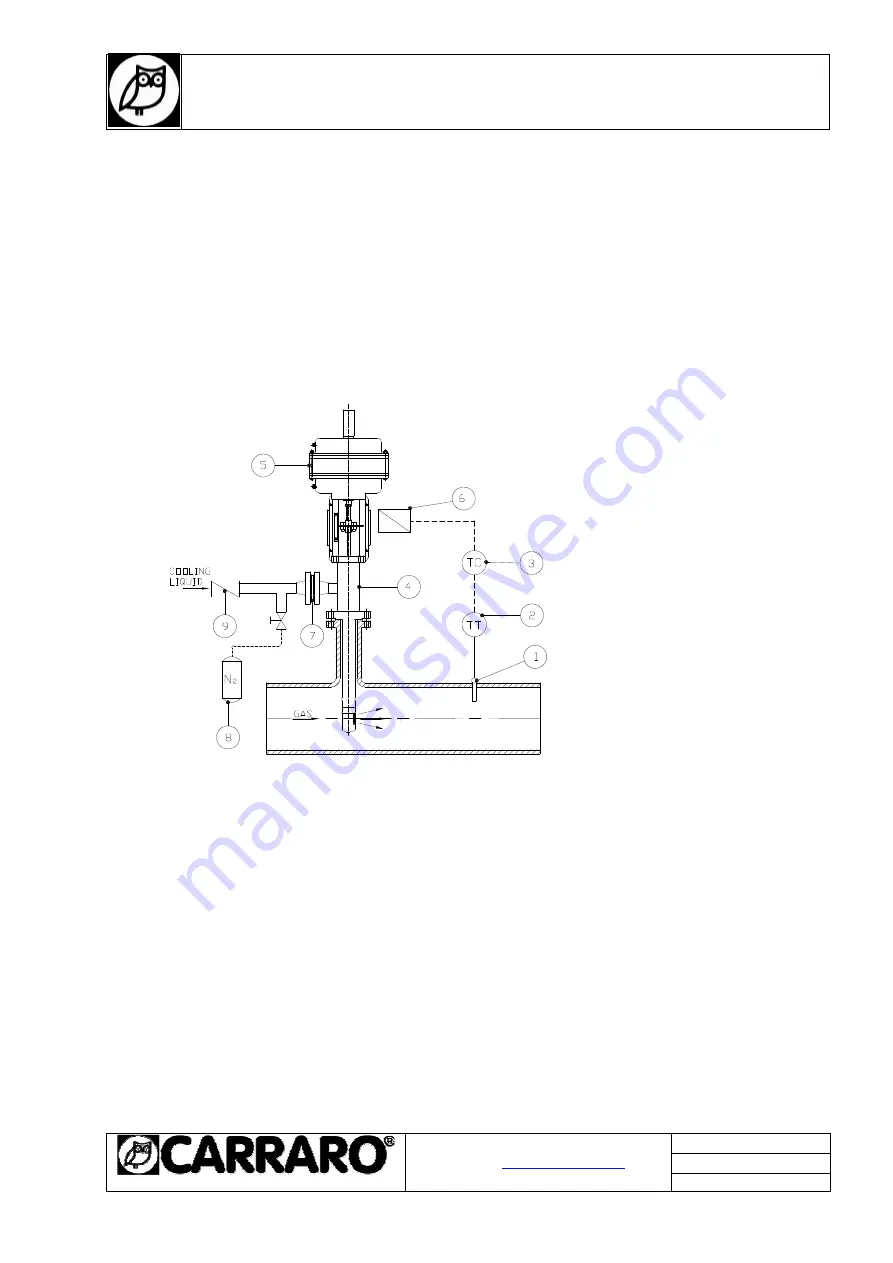

between the desuperheater and the sensor (see Fig. 3).

1) Temperature sensor

2) Temperature transmitter

3) Temperature control

4) Varicryo

5) Actuator

6) Positioner

7) Filter (Optional)

8) Auxiliary N2

9) Check valve

Fig. 3

The unit can be fitted on either horizontal or vertical pipes. The direction of liquid injection must

correspond to the direction of process gas flow. The desuperheater can be fitted at 90° to the vapour

pipe, regardless of direction of flow. The allowed orientations are outlined in Fig. 4. Vertically downwards

position must be achieved If installed horizontally, the unit must be mounted with a weight-compensation

system.