7

|

CarnivalKingSupplies.com

Frozen Beverage Dispenser

User Manual

Washing & Sanitizing

Condenser Cleaning

Washing

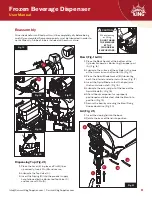

382SMM1, 382SMM2, 382SMM3 (Fig. 14)

Sanitizing

To maintain health standards and product quality, the machine must be cleaned daily.

Failing to clean daily will void this warranty.

Regular maintenance of the condenser ensures the quality of the product and efficiency of the machine.

This cleaning should be performed at least once a month.

Sanitizing must be done before the initial use of the

machine or if it is not used for an extended period of time.

•

Fill a basin with lukewarm water (Approx. 104°F)

and a neutral detergent suitable for plastic items.

•

DO NOT use abrasive powders which might affect

the bowl’s transparancy.

•

Wash all components (except the lid) in the basin.

•

DO NOT wash the lid by dipping in water. Doing so

may damage electric components.

•

Use a wet, soft cloth.

•

Rinse all parts carefully with clean lukewarm water

to remove any residual soap.

•

Dry all parts with a soft cloth.

•

If the machine will not be in use for an extended

period, cover and keep it away from dust.

•

Remove the left side stainless steel panel by

unscrewing the Fixing Knob.

•

Use a soft and dry brush to remove the dust from

the condenser fins.

•

When cleaning is complete, replace the side

panel and secure with Fixing Knob.

•

Follow washing instructions.

•

Make a solution of lukewarm water (Approx. 104°F)

and hypochlorite (bleach) with a 10g to 1L ratio.

•

Use a soft cloth or brush to apply the solution

to all components.

•

Rinse all parts carefully with clean lukewarm water

to remove any residual solution.

•

Dry all parts with a soft cloth.

DO NOT wash any components of the machine in the dishwasher.

CAUTION

The machine must be turned OFF and unplugged from the power source before cleaning.

CAUTION

Fig. 15