5

|

CarnivalKingSupplies.com

Frozen Beverage Dispenser

User Manual

Operation

Preparing The Product

Frozen Beverages

Cold Drinks

Concentrate

In order to obtain a homogeneous mix, the product will need

to be premixed before being added to the machine. Follow the

manufacturer’s recommendations for mixing.

Ready-to-Use & Premixed Concentrates

1.

Turn the machine OFF and unplug from power supply.

2.

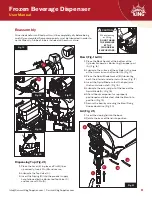

Pour liquid into the bowl. (Fig. 2)

3.

DO NOT pour below the MIN Level.

4.

DO NOT pour above the MAX Level.

1.

Position the Beverage Type Control Switch to I (Slush/Frozen

Cream Mode).

2.

Position the Spiral Blade Switch to I (ON).

3.

Wait for the mixture to freeze and test consistency. If

consistency is good, continue to step 5. If not, continue

to step 4.

4.

Thickness Control Knob is found behind the back panel of the

machine. The machine is set for optimal slush thickness by the

factory. Turn the screw L to R to increase thickness, R to L to

decrease thickness. (Fig. 3)

5.

Dispense the beverage by pulling the tap lever. (Fig. 4)

1.

Position the Beverage Type Control Switch to II (Cold Drink Mode).

2.

Position the Spiral Blade Switch to 0 (OFF).

3.

The optimal drink temperature has been set by the factory.

Use the Thermostat Control to adjust the temperature of the drink.

4.

To set temperature, open the transparent screen on the front panel

below the bowl and turn the Thermostat Screw.

5.

Dispense the beverage by pulling the tap lever. (Fig. 4)

In order to obtain a slush consistency, the mixture must have a

minimum sugar content of 13° BRIX (13g sugar to 100g solution).

A lower concentration may damage the spiral blades and gear motors.

Prepare the product separately before proceeding. It is

recommended to maintain a product level above the cylinder

evaporators for consistent cooling. (Fig. 5)

Over-icing and spiral blade jamming can

be caused by the wrong thickness setting.

CAUTION

Before using the machine, all food contact surfaces and components must be cleaned

and sanitized in accordance to the Washing & Sanitizing section of this manual.

CAUTION

Fig. 2

Fig. 3

Fig. 5

Fig. 4