NOTE

WA R N I N G

!

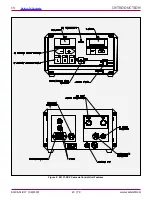

The 9060 Control

Unit must be located a minimum of 5’ (1.5 m) outside of

what is considered to be the hazardous area. Any mounting

method used must properly support the unit to a minimum

of 4X the unit weight.

See manual CP-13-07 for the installation

instructions for the 9060 control unit.

For safe use these applicators 79500, 79501

and 79523 must be used with the appropriate 9060

Control Unit part number 80131-XXX. For exact

configurations see the approved configuration draw-

ings in the front of this manual.

CAUTION

!

LOW VOLTAGE CABLE

Connect the low voltage cable from the control unit to the

applicator using a wrench to tighten.

Figure 10: Daisy Chained Cable

DO NOT

over-tighten the low voltage connection

at the applicator. The plastic parts could be damaged.

With the Vector design, multiple cables may be connected

together to create the length required, up to a maximum of

30m (100 ft.). To connect the cables, insert the male end

of one cable into the female end of the other. Tighten both

cable connectors against each other using two (2) 16mm

(5/8") open-end wrenches.

WA R N I N G

!

The electrical discharge that is available from

the charging electrode must not exceed 0.24 mJ of

energy. To achieve this limit, any flow of energy from

the paint supply through the paint line to the appli-

cator electrode must be prevented by grounding the

paint line at the applicator handle.

Verify that the applicator handle is actually ground-

ed before operating it! This is done with a fully

connected and operational system, by placing

one lead of an ohmmeter to the handle and the

other to the building electrical ground (cold water

pipe, building structure, steel, etc.). This reading

should be essentially zero.

If a greater reading is obtained, check that the

control unit is grounded. (See the control unit

manual for "Grounding Procedure.")

CAUTION

!

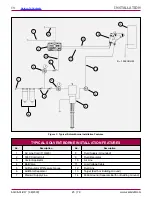

FILTERS

1. Install an air filter assembly on the air inlet of the control

unit. The filter should be 5 micron with a maximum

working pressure of at least 100 psig (6.9 bar). Screw

the fitting into the filter inlet. The filter MUST be installed

with the arrow pointing in the direction of flow. (Refer to

the appropriate Filter Assembly manual for "Installation

Instructions".)

When the applicator is triggered, the resulting air flow

closes the contacts of the air flow switch, thereby acti-

vating high voltage at the applicator.

2. Ransburg recommends that a fluid filter be installed

at the output of the fluid supply (pressure pot,

pump, circulating system, etc.). It is the end user's

responsibility to install the proper filter that meets their

system's requirements.

An air filter

MUST

be installed to permit proper

functioning of the air flow switch inside the control unit.

This unit must filter particles 5 microns and larger.

AH-06-01-R17 (08/2019)

26 / 79

www.carlisleft.com

INSTALLATION

EN