1700-1800° Tube

Internal Work Tube Supports

Work tubes may sag at high temperatures. The furnace is fitted with internal tube supports which

should be manually adjusted to suit the tube diameter.

With the tube fitted into the furnace, remove the back panel and identify the tube supports. In the

/300 models, there is 1 support. In the /600 models, there are 3. Adjust each support in turn, as

follows:

-

loosen the ring clip using a screwdriver;

-

push the ceramic tube upward until it just touches the

bottom of the work tube;

-

retighten the ring clip.

Note that it is advisable to lower the support tubes if the work

tube is removed or replaced, and later readjust them.

2.9

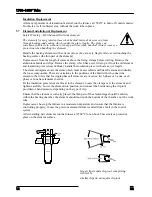

Tube Fittings (if ordered)

For optimum temperature uniformity, insulating plugs should be placed in the tube ends as shown

in fig.1. With a long work tube, the stem of the plug assembly should line up with the end of the

tube as in fig.2. Alignment of radiation shields is similar to that of plugs.

If stainless steel seals with gas inlets are supplied they are to be fitted as shown in fig.3; the stem

of any insulating plug or radiation shield should touch the seal.

If heavy fittings are to be clamped to the end of an extended work tube they can increase the

bending stress at the centre of the tube. Support such fittings in such a way that expansion of the

tube is allowed.

3.0

MF32

5

Содержание CTF

Страница 9: ...1700 1800 Tube 4 0 MF32 9 ...