Page 14

C621 C721 user manual.DOC

INJECTORS TABLE

Cat II 2H3+

NOMINAL

POWER

REDUCED

POWER

G30/G31

28-30/37 mbar

G20

20 mbar

BURNERS

[Hs - Kw]

[Hs - Kw]

Injector dial.

[1/100 mm]

Burners with

Safety valve device

Burners without

safety valve device

Injector dial.

[1/100 mm]

By-pass [1/100

mm]

By-pass [1/100 mm] By-pass [1/100 mm]

Semi-rapid (SR) 1,75

0,45

65

30

34

97

Adjustable

Rapid (R)

3,00

0,75

85

40

44

115

Adjustable

Triple ring (TR) 3,50

1,50

95

62

65

135

Adjustable

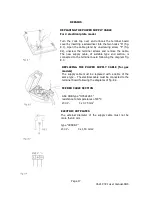

OPERATIONS TO BE PERFORMED WHEN SUBSTITUTING THE INJECTORS

•

Remove the gratings, the

burner covers and the

knobs;

•

Using a wrench, substitute

the nozzle injectors "J"

(Fig. 7.3 - 7.4) with those

most suitable for the kind

of gas for which it is to be

used.

The burners are made in such a way so as not to require the regulation of the

primary air.

REGULATING THE BURNER MINIMUM SETTING

When switching from one type of gas to another, the minimum flow rate must also be cor-

rect: the flame should not go out even when passing suddenly from maximum to minimum

flame.

To regulate the flame follow the instructions below:

•

Light the burner

•

Set the cock valve to minimum

On gas valves provided with adjustment screw in

the centre of the shaft

(fig. 7.5):

•

Using a screwdriver with max. diameter 3 mm, turn

the screw inside the tap until the correct setting is

obtained.