Chapter 2

2-7

2.2.3 Print Position Adjustment Function

0012-6313

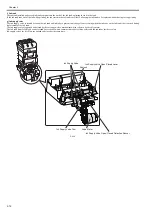

This printer supports a print position adjustment for the vertical and horizontal print positions, the bidirectional print position of the printhead mounted on the car-

riage, and the feedrate.

There are two adjustment modes for the print: automatic adjustment, in which print position adjustment patterns printed are detected by the multi sensor attached

to the lower left part of the carriage, and manual adjustment, in which print position adjustment patterns that are slightly modified from one another are printed, so

that visually verified adjustment values can be set from the operation panel.

To make print position adjustments, A3-or-larger-sized roll media or cut media are needed.

2.2.4 Head Management

0012-6314

This printer supports a nozzle check function to spot non-discharging nozzles in the printhead.

When the printer detects a non-discharging nozzle, it starts cleaning the printhead automatically to correct its discharge failure. If cleaning does not work, the printer

backs up the non-discharging nozzle with an alternative nozzle automatically to ensure unfailing print performance.

Detection timings (automatic):

Power-on, carriage cover open detection, print start (check timing variable by selecting Nozzle Check from the system menu).

2.2.5 Printhead Overheating Protection Control

0012-6315

When an abnormal temperature rise in the printhead is detected, overheating protection control launches.

Overheating could occur in the printhead after a period of print operations without the nozzles being filled with inks.

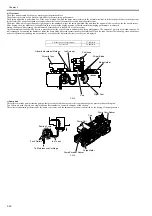

Overheating protection control is implemented on the basis of the temperature detected by the head temperature sensor for each nozzle. When an abnormal temper-

ature is detected in any nozzle train, overheating protection control is exerted at one of two levels according to that temperature.

Protection level 1:

If the head temperature sensor (DI sensor) detects a temperature higher than the protection temperature, it halts the carriage temporarily at the scan end position in

the direction of travel according to the carriage scan status.

Printing resumes when the printhead radiates naturally to cool down below a predetermined temperature or when 30 seconds or longer have elapsed since the de-

tection of the higher temperature.

Protection level 2:

If the head temperature sensor (DI sensor) detects a temperature higher than the abnormal temperature, the printer shuts down the print operation immediately,

moving the carriage to the home position for capping, with an error indication on the display.

2.2.6 Pause between Pages

0012-6320

An inter-page function is available to prevent ink rubbing, which keeps paper just printed hanging above the platen and waiting for a predetermined period of time

before delivery.

The wait time is user-programmable from the print driver. This feature is particularly useful on paper that takes time to dry after printing, such as film.

2.2.7 White Raster Skip

0012-6322

This printer supports a white raster skip function to bypass carriage scanning in a consecutive sequence of voids in print data, for added throughput.

2.2.8 Sleep Mode

0012-6324

The printer has sleep mode to reduce its standby power requirement.

The printer transitions to sleep mode automatically when it has been left idle or no print data has been received for a predetermined period of time while the printer

is online or offline.

The printer exits sleep mode when any operation panel key is activated or print data is received from the host computer.

The time to transition to sleep mode is variable from the operation panel (Default: 5minutes).

2.2.9 Shut Down Mode

0031-2532

The power supply of printer turns off automatically to reduce the power consumption when the sleep mode is continued for a predetermined period of time.

The time to transition to shut down mode can be changed by the operation panel (Default: 8 hours).

Содержание image Prograf iPF780 Series

Страница 1: ...Mar 27 2014 Service Manual iPF780 760 750 series iPF785...

Страница 9: ...Chapter 1 PRODUCT DESCRIPTION...

Страница 57: ...Chapter 2 TECHNICAL REFERENCE...

Страница 117: ...Chapter 3 INSTALLATION...

Страница 125: ...Chapter 4 DISASSEMBLY REASSEMBLY...

Страница 133: ...Chapter 4 4 7 3 Remove one screw 1 release two hooks 2 and then remove the output guide middle left 3 F 4 11 1 3 2 2...

Страница 175: ...Chapter 4 4 49 2 Shaft Cleaner 1 F 4 97 1 1...

Страница 176: ...Chapter 4 4 50 3 Upper Cover Hinge Catch 1 Roll Cover Slide Guide 2 F 4 98 2 1...

Страница 179: ...Chapter 5 MAINTENANCE...

Страница 186: ...Chapter 6 TROUBLESHOOTING...

Страница 212: ...Chapter 7 SERVICE MODE...

Страница 267: ...Mar 19 2014 PARTS CATALOG iPF786 785 781 780 765 760 755 750...

Страница 275: ...STAND UNIT ST 33 STAND UNIT ST 34 100V Q51 1767 000 230 KOR Q51 1768 000 Q51 2560 000 Q51 2800 000...

Страница 299: ...2 23 FIGURE 09 CUTTER UNIT J12 J7 J11 J31 J34 J33 A A 10 8 1 502 7 5 13 13 9 11 8 501 6 12 2 3 4 14 14 14 15 503...

Страница 301: ...2 25 FIGURE 10 PLATEN GUIDE UNIT 1 3 6 2 8 4 5 10 10 10 9 9 11...

Страница 326: ......