TF2101, TF2111, TQ3010, TQ3011, TX2101, TX2118

7

Maintenance

(Continued)

AIR FILTER

Never run the compressor pump

without an intake air filter nor

with a clogged intake air filter. Use

compressed air to blow the filter clean.

Do not wash or oil the element. If it

cannot be blown clean, the filter must

be replaced. Operating compressor

with a dirty filter can cause high

oil consumption and increase oil

contamination in the discharge air.

INTERCOOLER (TWO-STAGE

COMPRESSORS ONLY)

Intercooler fins

are sharp, always

wear gloves and use care when you

clean or work near the intercooler.

Weekly, check the intercooler to be sure

all fittings are secure and tight. Blow all

dirt, dust and other accumulations from

the intercooler fins.

COMPONENTS

Turn off all power and use light air

pressure to blow dust and foreign

material from cylinder head, motor, fan

blades, air lines, intercooler and tank

on a monthly basis.

BELTS

Lock out and tag

the power then

release all pressure from the tank to

prevent unexpected movement of the

unit.

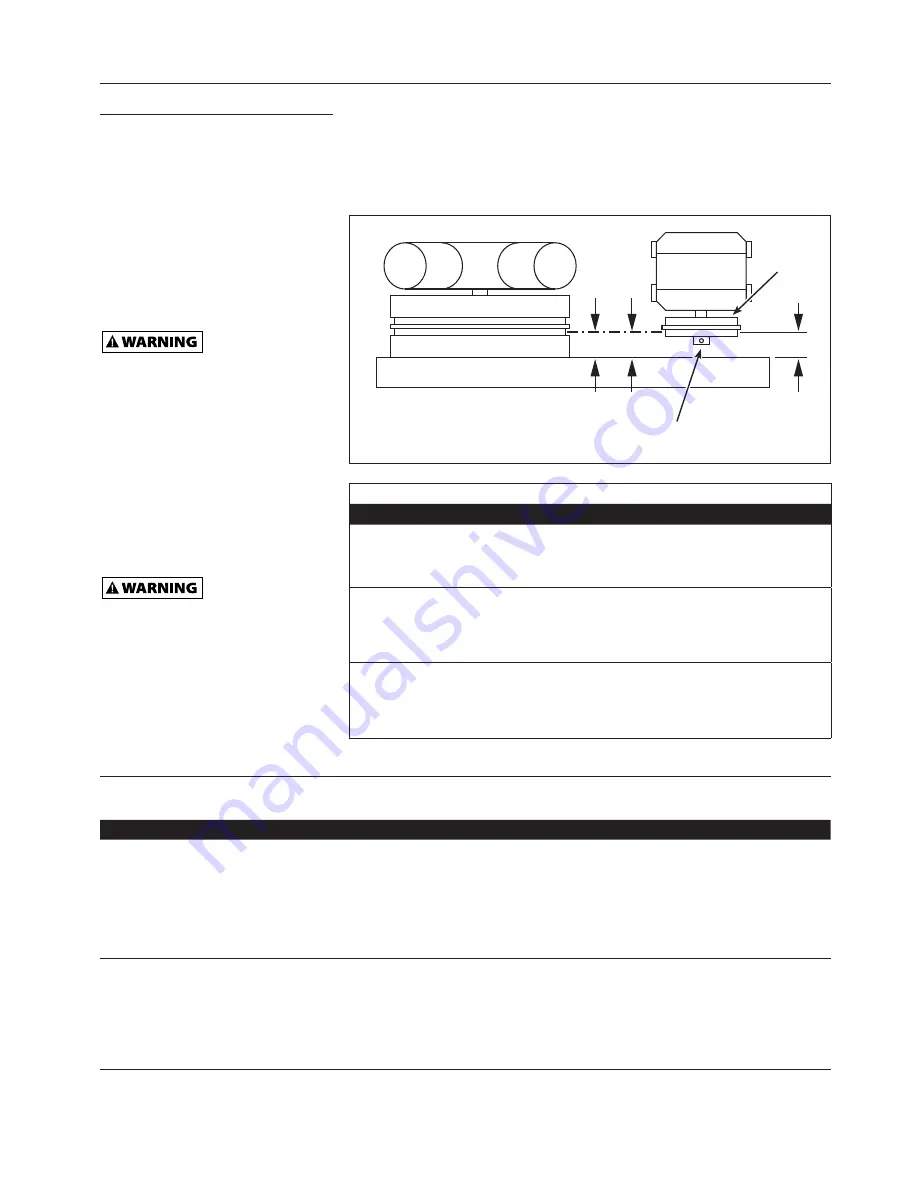

Check belt tension every 3 months.

Adjust belt tension to allow 3/8 to 1/2

inch deflection with normal thumb

pressure. Also, align belts using a

straight edge against the face of the

flywheel and touching the rim on both

sides of the face. The belts should be

parallel to this straight edge (see

Figure 9). Dimension A should be the

same as B and C to ensure proper

alignment of the belts.

Slots in the bed-plate allow for sliding

the motor back and forth to adjust belt

tension.

STORAGE

If compressor is to be stored for a short

period of time, make sure that it is

stored in a normal position and in a

cool protected area.

�

B

C

Air Compressor

Motor

Flywheel

Straight Edge

Setscrew

Motor

Drive

Pulley

Figure 9 - Top View

Troubleshooting Chart

Symptom

Possible Cause(s)

Corrective Action

Motor hums and

runs slowly or not

at all

1. Low voltage or no voltage

1. Check with voltmeter, check overload relay in magnetic starter or reset

switch on motor. If overload or reset switch trips repeatedly, find and

correct the cause. See next item

2. Shorted or open motor winding

2. Replace motor

3. Malfunctioning check valve or

unloader valve

3. Replace check valve or unloader valve

4. Malfunctioning pressure switch -

contacts will not close

4. Repair or replace pressure switch

Reset mechanism

cuts out repeatedly

or fuses blow

repeatedly

1. Pressure switch set too high

1. Adjust or replace

2. Malfunctioning check valve

2. Clean or replace faulty valve

3. Incorrect fuse size or magnetic

starter heaters

3. Be sure that fuses and heaters are rated properly

4. Malfunctioning motor

4. Replace motor

5. Loose Wiring

5. Check all electrical connections

MAINTENANCE SCHEDULE

Operation

Daily

Weekly

Monthly

3 Months

Check Safety Valve

�

Drain Tank (See Figure 6)

�

Check Oil Level

�

Clean or Change Air Filter

�

Check Intercooler (two-stage

compressors only)

�

Clean Unit Components

�

Check Belt Tightness

�

Change Oil (See Figure 5)

�

Change Oil Filter (Pressure

lubricated pumps only)

�

All manuals and user guides at all-guides.com