10

FILTER CHANGE-OUT

(Replacing Contaminated Filters Or Adsorbers)

Consult your safety officer before beginning filter change-out, to assure all proper procedures are

followed for your application.

Note: Filtration housings that contain more than one filter/adsorber are equipped with filter removal rods.

Filtration housings containing multiple prefilters also are equipped with removal rods. The filter removal rod can

be operated from inside the change-out bag to aid in removing the second or third filter/adsorber inside the

housing. To operate the filter removal rod, grab the handle from inside the bag glove and pull filter/adsorber

towards you. It is recommended on all multi-filter change-outs that the first filter/adsorber be removed by hand

to lighten the load that will have to be pulled by the removal rod. Adsorbers are very heavy, and it may require

a hard pull to remove them from the housing. For filtration housing containing three (3) adsorbers, it may be

necessary to remove the second adsorber by reaching inside the filtration housing and pulling the adsorber out

by hand.

1. Before replacing a contaminated filter(s)/adsorber(s), the airflow through the filtration system must be

stopped. This can be performed by shutting-down the system, or bypassing the airflow through the system

to another system, when applicable. To minimize possible contamination, close upstream and downstream

dampers (if equipped). It is recommended that protective clothing, gloves, and respirators be worn when

changing filters with dangerous contaminants. Consult your safety officer before beginning filter change-

out to assure all proper procedures are followed for your application.

2. To gain access to the inside of the filtration housing, remove the housing access doorknobs by turning

counter-clockwise (for housings equipped with swivel latches: do not remove doorknobs; loosen and swivel

door bolt out from door corner retainer). Pull the access door straight towards you to remove.

3. To remove a prefilter, or header track filter, extend the change-out bag and follow steps 4 through 6. When

removing filters or adsorbers sealed by a locking mechanism, extend the change-out bag and release the

locking mechanism handle from the handle latch. Slowly open the locking mechanism by pulling the handle

fully open, this will pull the filter away from the knife-edge sealing surface. Upon completion follow steps 4

through 6.

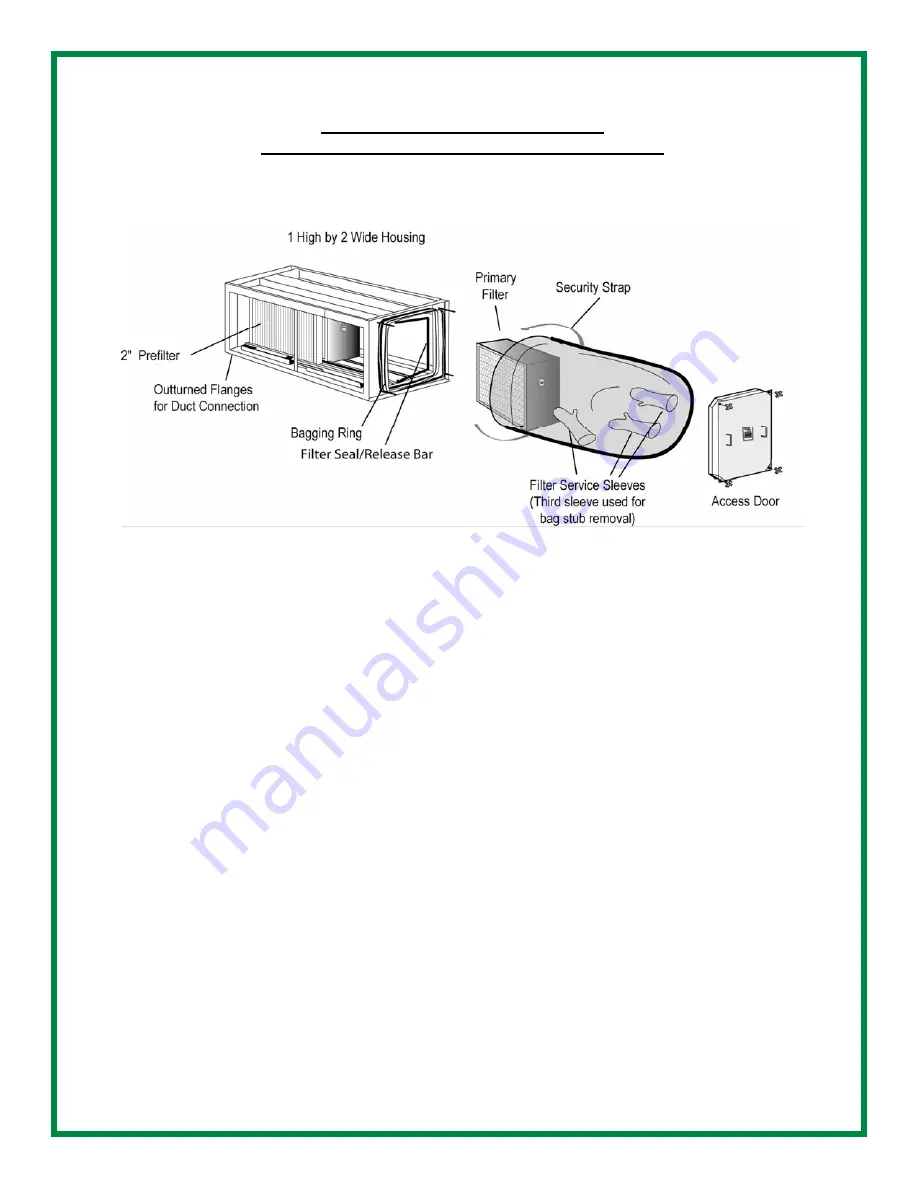

Bag-In/Bag-Out Concept