18

Safety and alarms

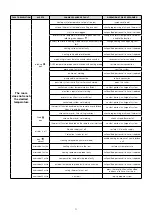

Safety thermostat cut-out (SATK2210.)

Error code 69

HIUs configured to support low temperature heating continuously

monitor the safety thermostat controlling the flow temperature.

If the safety thermostat is activated during a general cycle, the heating

circulation pump immediately comes to a stop and the modulating

valve is completely closed.

After the user has removed the block imposed by the safety

thermostat, operation can only be re-enabled when the modulating

valves are completely closed again.

This means that if a domestic water cycle is in progress, the activation

of the shut-off valve will be postponed until the end of that domestic

water cycle.

Corrective action

To restore the operating mode press the manual RESET button.

preriscaldo

ricircolo

Impostazione default limitazione

portata massima

Esempio limitazione portata massima

Errori

Intervento del relè

Errori

Errori

Errori

Errori

preriscaldo

ricircolo

Impostazione default limitazione

portata massima

Esempio limitazione portata massima

Errori

Intervento del relè

Errori

Errori

Errori

Errori

preriscaldo

ricircolo

Impostazione default limitazione

portata massima

Esempio limitazione portata massima

Errori

Intervento del relè

Errori

Errori

Errori

Errori

preriscaldo

ricircolo

Impostazione default limitazione

portata massima

Esempio limitazione portata massima

Errori

Intervento del relè

Errori

Errori

Errori

Errori

preriscaldo

ricircolo

Impostazione default limitazione

portata massima

Esempio limitazione portata massima

Errori

Intervento del relè

Errori

Errori

Errori

Errori

Thermal safety solenoid valve (SATK2210.)

Error code: 76

Corrective action

Normal operating conditions are restored automatically once the faulty

safety valve works properly again.

preriscaldo

ricircolo

Impostazione default limitazione

portata massima

Esempio limitazione portata massima

Errori

Intervento del relè

Errori

Errori

Errori

Errori

If the electronic circuit board detects a fault, the display shows the

error code concerned and the symbol

mandata a punto fisso

impostazione temperatura di

mandata

limite temperatura ritorno

alta/bassa temperatura

compensazione

intervento limite temperatura ritorno

climatica

.

Heating flow probe fault (SATK2210. - SATK2220.)

Error code: 5

Domestic hot water probe fault

Error code: 6

Return probe fault

Error code: 15

Corrective action

Normal operating conditions are restored automatically once the

faulty probe works properly again (see page 21 - “Temperature probe

replacement”).

External temperature fault

Error code: 38

antilegionella

The HIU is disabled due to an incorrect connection on the circuit

board front terminals or due to an input from an external device

indicating zero credit.

Corrective action

Check the electrical connections or, in the case of zero credit, top-up

the external device/contact the service supplier.

Heat interface unit disabled

Error code 80

<mode>

ACS ON/OFF

Risc. ON/OFF

<set>

Ora/giorno corrente

Temperature di set point

k regolazione climatica

<day/night>

Set diurno/notturno

<temp>

Visualizzazione

temperature

(set point am

sonde)

<prog>

Programmazione oraria

riscaldamento e funzione

“comfort”

<reset>

Reset errore riarmabile/funzione

scaldamassetto

<R>

+/-