19

Plumbing Connections

IMPORTANT! Always check local codes prior to any in-ground spa

installation.

Once the spa and equipment are properly located, you will want to lay out

the plumbing run.

Trenches should be deep and wide enough to allow all pipes to be buried

below the frost line and should be in as straight a line from the spa to the

equipment as possible. Check local code requirements for underground

pipes. Always know what is under the ground before you dig anywhere.

You will need 2” flex or PVC lines for your suction, intake, and air line. In

ground spas have marked intake and suction lines, making it easy find and

connect to and from the spa and equipment pack.

The plumbing run should not be any longer than 15 feet to maximize

water pressure. Another way to maximize water pressure is to limit (or

even eliminate) the use of 90˚ elbows in your plumbing run. A more direct

plumbing run using 45˚ elbows is more efficient, and promotes increased

water pressure.

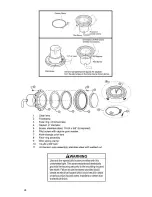

Identifying Plumbing Lines

The spa’s plumbing lines are clearly marked during water testing at the

factory. This is done to assist installers in properly identifying the installation.

We still recommend that the installers verify plumbing lines prior to gluing.

This can be done by using one of the following techniques.

Air Test

The air test requires a wet/dry vacuum. Locate the plumbing line you

wish to identify and secure the vacuum hose to cut open end. Turn on the

vacuum, enter the spa and listen for vacuum suction sound from inside the

spa side filter canister. If you hear the suction sound in the canister, the

line is properly marked and can be connected to the suction side of the

pump on the equipment pack.

Water Test

The water test requires a garden hose and water source. Locate the

plumbing line you wish to identify and secure the outlet side of the garden

hose to cut open end. Turn on the water supply to the garden hose, enter

the spa and look for water inside the spa side filter canister. If you see

water in the canister the line is properly marked and can be connected to

the suction side of the pump on the equipment pack.

If any plumbing line is not properly marked or not marked at all, follow

either the air or water test procedure until all lines are identified prior to

gluing.

Содержание Avalon A726B

Страница 1: ......

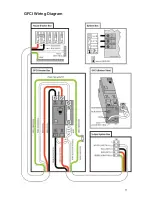

Страница 13: ...11 GFCI Wiring Diagram...

Страница 17: ...15 RCD Wiring Diagram...

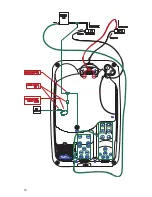

Страница 18: ...16 Installing the In Ground Shell...

Страница 20: ...18...

Страница 26: ...24...

Страница 31: ...29...