4

4

4

Adjustments

4..

Adjusting the Printhead Position

In order to achieve the best possible print image the following printhead settings are necessary:

Align the heating line with the highest point of the print roller. Density of the print image is the greatest at this

point.

Set the parallelism of horizontal lines with the edge of the label.

!

Attention!

The printhead assembly can be damaged.

Attempting to adjust the printhead when the fixing screws (3) are tight can lead to defects at the printhead

assembly.

Always loosen the fixing screws (3) before adjusting the printhead.

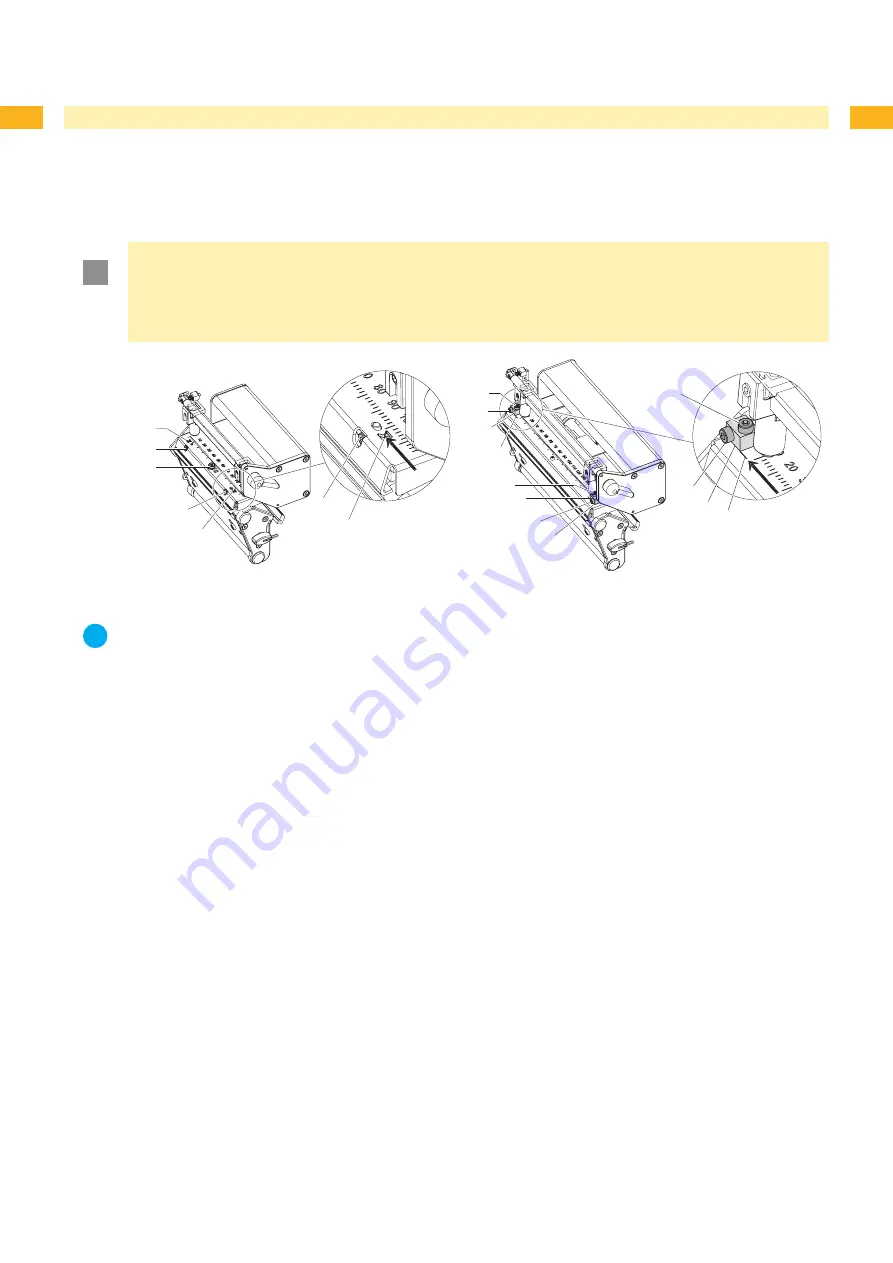

1a

2a

3

2b

1b

1b

2b

2b

2a

3

3

5a

4a

4b

5b

2a

5a

4a

3

Fig. 23

Adjusting the printhead position (left side A2+, A4+, A4.3+ / right side A6+, A8+)

i

Notice!

Open and close the printhead lock after each step of the adjustment.

Check the alignment of the printhead A2+, A4+, A4.3+ in the adjustment windows (1), at A6+, A8+ at the slides

(5).

If the printhead is not aligned properly, loosen the screw (3) about one quarter turn.

If the printhead is not aligned properly, use the screws (2) to align at A2+, A4+, A4.3+ the lines on the printhead

with the tips of the grooves, at A6+, A8+ the lines on the printhead mounting bracket with the front edge of the

slides (5).

- Screw (2a) effects the inner half of the printhead, and screw (2b) the outer half.

- Turning clockwise moves the printhead at A2+, A4+, A4.3+ forward, at A6+, A8+ backward.

Create print samples with the test function

Test grid

(

Configuration Manual) or a similar print pattern.

If the horizontal lines in the test grid are not parallel with the label edges, adjust the parallelism with the screws

(2).

Set the best possible image quality by maintaining parallelism via turning the screws (2a) and (2b) in an alter-

nating fashion.

Differences in the density between the two sides are still permissible.

Tighten the screws (3).

When the parallelism of the printhead is set, continue with the adjustment of the printhead pressure

4.2.3 on page 25.

•

•

1.

2.

3.

4.

5.

6.

7.

8.