Operation and Maintenance Instructions for

T

T

T

T

Tomaha

omaha

omaha

omaha

omahawk

wk

wk

wk

wk

Spray Guns

Operation

1. Connect air supply hose at handle of gun.

2. Connect a pressurized fluid supply to the gun fluid inlet.

3. Fluid flow can be controlled using the fluid control knob, this restricts flow by limiting needle travel. It is best to control

fluid flow by proper selection of fluid orifice size and use the fluid control knob to “fine tune flow rate”.

4. Fan width can be adjusted using the fan control knob. Turning the knob clockwise narrows the fan.

Maintenance

IMPORTANT! Routine cleaning and maintenance is essential to insure proper gun operation.

Several states prohibit spraying solvent into the atmosphere and require the use of covered gun cleaner.

1. If a gun cleaner is being used, connect and clean the gun in the gun cleaner according to the manufactures

instructions.

2. If a gun cleaner is not being used:

Remove air cap and clean separately using clean solvent.

For pressure setups, connect a pressurized solvent supply to the fluid inlet, trigger the gun allowing solvent to flow

thru the gun until clean.

NOTE: Gun head disassembly is not recommended for normal cleaning and maintenance.

Not recommended to soak entire spray gun in solvent.

Gun head disassembly and reassembly instructions:

Have repair kit # 10-140 available before gun disassembly.

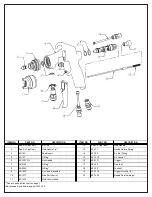

Disassembly

1. Remove the trigger by removing both screws (19).

2. Remove fluid control knob (11).

3. Remove needle return spring (13) and needle (12).

4. Remove air valve assembly (9) using a 9/16” wrench.

5. Using a 7/16” wrench remove the needle seal cartridge (20).

6. Using a 13 mm wrench remove the side port control (10) and air control (15).

7. Using a 11/16” wrench loosen locknut (18), using a 5/8” wrench remove fluid inlet (17).

8. Remove air cap (1), remove fluid tip (2) using a 3/8” socket.

9. Using a 1” wrench remove head insert (3).

Reassembly

1. Install a new o-ring (7 and 8) on air valve assembly, lightly lubricate o-rings with vasoline and reinstall air valve (9) into

the gun body (6).

2. Install a new seal (5) in gun body (6). Reinstall head insert into gun body and tighten. Reinstall fluid tip (2) and tighten.

3. Install new seal (5) in gun body. Reinstall and tighten fluid inlet (17). Tighten locknut (18) after fluid inlet has been

tightened.

4. Remove the shipping pin from a new needle seal cartridge (20). Install new needle seal cartridge (20).

5. Reinstall side port control (10) and air control (15).

6. Reinstall needle (12), needle return spring (13) and fluid control knob (11).

7. Reinstall air cap (1).