MAINTENANCE

OPERATOR MANUAL

66

EPS14P

67

OM-EPS14P2019001-EN

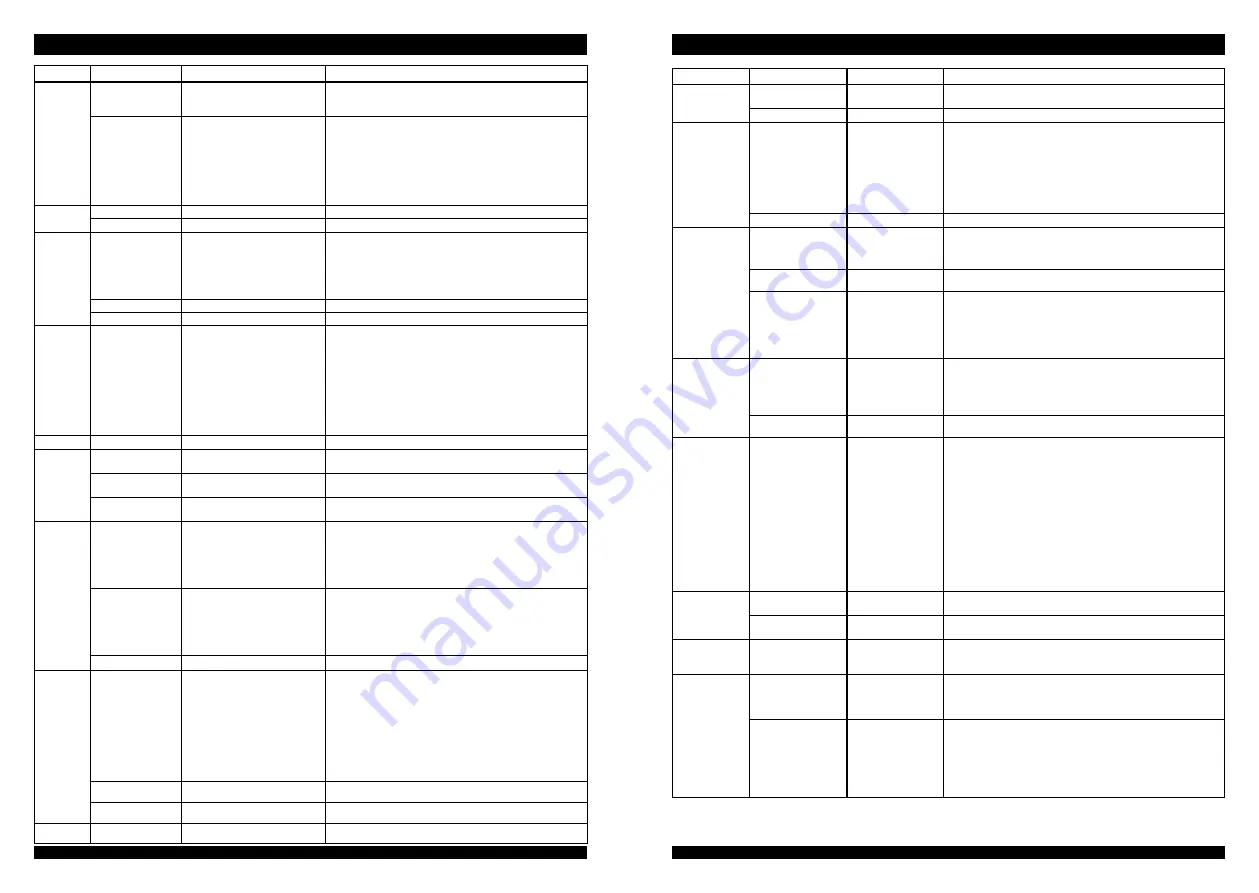

Display

ALARM

Fault name

Recommended inspection

02A68

SMARTDRIVER KO

Drive of electromagnetic brake

fault

Check whether the high end (CNB#1) of the drive of

electromagnetic brake is short circuited to the terminal B-.

If not, the internal drive module could be damaged.

W A I T I N G F O R

NODE

Waiting for signal from a node

In the CAN communication network, a certain controller

has received the signal that another controller cannot

communicate normally. The said certain controller hence

remains waiting until the whole CAN communication

network reverts to normality. Check the controller that

cannot communicate normally for failed connection. Check

whether the software version or parameter settings are

correct.

02A70

encoder error

Encoder fault

Check the motor encoder

EPS RELAY OPEN

EPS relay open

Check whether the EPS controller has fault

02A71

EEPROM KO

Memory is damaged

Forklift does not travel. Parameter storage becomes faulty

so that forklift stops operation. Operate the key switch for

several times. If the fault still exists, replace the logic card.

If the fault disappears, parameters previously stored have

been replaced by wrong parameters. It is imperative to set

the parameters again.

HANDBRAKE

handbrake

02A72

VMN LOW

VMN low

Cause: When the motor is turned on, the high-end voltage

of MOS tube is less than 66% the capacitor voltage, or

when the motor is running, the high-end voltage of MOS

tube is less than the requirement. Possible causes:

1.Incorrect phase connection or faulty circuit of the motor.

Check the motor for incorrect phase connection. Check

the motor for current leakage to the ground. Check the

motor for broken coil.2.Check whether the main contactor

engages securely. Check the contacts for wear.

3.Replace the controller.

02A73

sens.Motor temp.ko Motor temperature sensor error Check harness of motor temperature sensor.

02A74

DRIVER SHORTED

Short circuit of contactor

Check whether there is short circuit in the coil output from

the controller. If not, replace the controller

AUX BATT.SHORT.

Fault with auxiliary drive voltage Check whether BI is correctly connected to B5. If so, replace

the controller;

DRV.SHOR.EV

Short circuit of EV cable

Check whether the low end of EV1/EV2/EV3 is short

circuited to B-. If not, it is required to replace the controller;

02A75

C O N T A C T O R

CLOSED

Contacts of contactor get stuck

Before energizing the coil of main contactor, the controller

will check whether the contacts of main contactor get stuck.

Attempt to discharge the capacitor. If the capacitor voltage

is reduced by 20% the battery voltage, the fault could exist.

1. Check whether the contacts of the contactor get stuck. If

so, replace the contactor.

CONTACTOR DRIV-

ER

Short circuit of drive

With the key switch turned to “ON”, the microprocessor

will check the drive of main contactor for short circuit. In

case of short circuit, the warning will be displayed. Check

whether the positive terminal of coil of main contractor is

short circuited to A16 or negative terminal of power supply.

If externality is normal, replace the controller.

CONT.DRV.EV

EV drive of the controller is inoperable

Replace the controller;

02A76

KEY OFF SHORTED Short circuit of the key switch

In the startup phase, if the controller detects a low logic level when

the key switch is turned to “OFF”, this fault will be displayed. Fault

analysis: A highly possible cause is voltage being too low. Perform the

following checks. -Key switch based external load (for example, turning

on the DC-DC converter. Relay or contactor switch input signal lower

than startup voltage).-Check the connections of the power supply

cables to the positive and negative terminals of the battery, and to

the terminals -BATT and + BATT terminals of the main contactor and

controller. The screws shall be tightened to torque 13Nm to 15Nm.-If

no voltage drop in the power supply circuit is detected, this fault will be

reported each time the key switch is turned to “ON”. The hardware of

controller could become faulty. It is necessary to replace the controller.

COIL SHOR.MC-EB

Main contactor or elec-tromagnetic

brake is heavily loaded

1. Check whether the output and load of the controller are excessive; 2.

Replace the controller;

COIL SHOR.EV.

PEV coil fault

Fault with the PEV drive coil. Check whether the PEV drive coil

connection or the coil itself are in good conditions;

coil shorted

Short circuit of coil

Check whether there is short circuit of main contactor coil and oil pump

contactor coil

Display

ALARM

Fault name

Recommended inspection

02A77

CONTACTOR OPEN

Main contactor open 1. Broken circuit of main contactor coil. 2. Main contactor

damaged

end teach ko

Not used in BYD system

02A78

VACC NOT OK

Accelerator fault

Inspection time: With the forklift idling, the accelerator voltage is at

least 1V higher than the minimum set in the “PROGRAM VACC”

menu for accelerator signal range.

Possible causes:

1.Upper and lower limits of accelerator voltage are not taken. Move

to the PRPGRAM VACC menu to take the limits again.

2.Accelerator error. Possible cause is that accelerator pedal failure to

return to original position, or internal error of accelerator.

3.Controller fault.

Possible causes:

02A79

INCORRECT START

Star tup sequence

fault

Incorrect startup sequence. Possible causes:

1.The direction switch has already been turned on before the motor is

turned on.2.Operation sequence error.3.Incorrect wiring connection.

4.If the fault cannot be eliminated, replace the controller.

WRONG STEER PAR.

PUMP INC START

Oil pump startup se-

quence fault

Incorrect oil pump startup sequence. Possible causes:

1.The “LIFT” or “TILT” switch has already at the “ON”

position before the forklift is started.

2.Operation sequence error.

3.Incorrect wiring connection.

4.If the fault cannot be eliminated, replace the controller.

02A80

FORW + BACK

Forward and reverse

signals exist at the

same time (direction

switch gets stuck)

The controller can keep checking for this fault. Having detected

that request signals in the two directions occur at the same

time, the controller will issue a warning. Possible causes:

1.Wire damaged2.Direction switch fault3.Improper operation

4.If the fault cannot be eliminated, replace the controller

EMERGENCY

02A82

ENCODER ERROR

Encoder fault

The controller detects that two successive speed readings of the

encoder differs greatly from each other. A normal encoder in

the system cannot change speed readings greatly within a very

short time. Hence, a possible cause for the symptom is that the

wires of one or more encoders are worn or broken. Check the

mechanical and electrical parts of the encoder. Another possible

for the symptom is electromagnetic interference from the

sensor bearing. If the symptom is not due to the two causes,

replace the controller.Note: Sometimes manual operations may

also cause this fault indicating on the controller. In these cases,

it is required to turn off power supply and start the forklift

again. For example:1.The forklift suddenly collides with an

obstacle so that it is incapable of travelling;2.The driver applies

the brake sharply while the forklift is travelling at a high speed.

02A84

CAN BUS KO BMS

BMS communication

fault

Check whether the BMS communication line operates normally.

canbus ko bms

BMS communication

fault

Check CAN communication wire

02A85

VACC OUT RANGE

Accelerator input

i s o u t s i d e t h e

permissible range.

1. Upper and lower limits of accelerator voltage are not correctly

taken. Move to the PRPGRAM VACC menu to take the limits

again; 2. Check whether the accelerator connection is correct;

02A86

PEDAL WIRE KO

Fault with connection

o f p o s i t i v e a n d

negative terminals of

accelerator

Check whether the positive and negative terminals of the

accelerator have been connected to the controller;

POS.EB.SHORTED

High end of drive

of electromagnetic

b r a k e p r o v i d e s

output earlier than

expected

High end of drive of electromagnetic brake outputs high voltage

with the interlock not engaged. 1. Check whether another high

voltage circuit is connected to the high end output connector

of electromagnetic brake; 2. If the high end output connector

of electromagnetic brake is not connected but high voltage

still exists, the drive circuit in the controller has already been

damaged;

Содержание EPS14P

Страница 1: ...EPS14P OPERATOR MANUAL OM EPS14P2019001 EN...

Страница 2: ...EPS14P OPERATOR MANUAL OM EPS14P2019001 EN...

Страница 38: ......