3

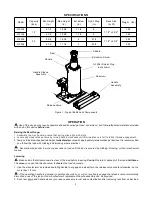

Model

Capacity

(tons)

Min. Height

(in.)

Max. Height

(in)

Ext. Screw

(in)

Hyd. Lifting

(in)

Base Size

(L x W)

Weight (lbs)

J10124

9 1/2

18 5/8

3 1/8

6

19.6

J10126

6 1/8

10 5/8

1 1/2

3

16.5

J10204

9 5/8

18 3/4

4

5 1/8

29.3

J10206

6 1/2

11 1/4

2

2 3/4

22.2

12

20

7 1/2" x 4 5/8"

7 1/2" x 5 3/8"

!

!

SPECIFICATION

S

Figure 1 - Typical Bottle Jack Components

Handle

Assembly

Saddle

Handle Sleeve

Assembly

Handle

Oil Filler Screw/ Plug

(not shown)

Release Valve

Extension Screw

Ram

Reservoir

OPERATION

Use of this device may require special skills and knowledge. Read, understand, and follow

all

printed materials provided

with and on this device

before use

.

Raising the Ram Plunger

1. Assemble the 3-pc handle, ensure that spring clips align with slots.

2. Locate and close release valve by turning handle clockwise until firm resistance is felt to further thread engagement.

3. Pump until load reaches desired height.

Immediately

secure with appropriately rated mechanical devices. It is recommended

you follow the load with cribbing and blocking where practical.

Never allow personnel to work or pass under a load until the load is secured by cribbing, blocking, or other mechanical

means.

Lowering

Make certain that all personnel are clear of the load before lowering.

Control

the rate of descent of the load

at all times

.

The

more

you open the release valve, the

faster

the load descends.

1. Use the manufacturer's provided operating handle to engage and slowly turn the release valve counter-clockwise, but no

more than 1/2 turn.

If the operating handle is damaged, operates abnormally, or will not positively engage the release valve, immediately

discontinue use of the jack until a manufacturer's replacement handle assembly can be acquired.

2. Push ram down and handle sleeve in to reduce exposure to rust and contamination after removing jack from under load.

!

!