INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 26 of 66

• Move the beading disc away from the wheel.

• Remove the grippers and fit them in the same posi-

tion (6 o’clock) outside the second bead.

• Turn the mandrel 90° clockwise until the grippers

are at 9 o’clock.

• Move the beading disc forward until it is inside the

edge of the rim by about 1-2 cm, making sure it is

approximately 5 mm from the profile. Begin clock-

wise rotation making sure that, after a 90° turn, the

second bead begins to slide in the rim groove.

• Once insertion is completed, move the tool away from

the wheel, turn it over into “out of work” position and

remove the grippers.

• Lower the mandrel until the wheel rests on the

footboard.

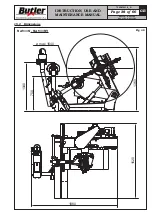

• Move to work position

A

(

Fig.

_

6

).

• Close the mandrel jaws completely, making sure the

wheel is held up to avoid dropping.

MAKE SURE THAT THE WHEEL’S

HOLD IS SECURE TO AVOID IT

FALLING DURING REMOVAL. FOR

HEAVY AND/OR VERY LARGE

WHEELS USE AN ADEQUATE LIFT-

ING DEVICE.

• Translate the movable footboard to release the wheel

from the same mandrel. With especially soft tyres,

simultaneously insert both beads on the jaw so that

bead insertion in the tyre is done only once; this

single operation is ideal for saving time.

With hook tool

Proceed as follows:

• Secure the rim to the mandrel according to the proce-

dure described in paragraph “WHEEL CLAMPING”.

• Adequately lubricate the tyre beads and the rim bead

seat with a suitable lubricant using the provided

brush.

USE ONLY TYRE LUBRICANTS.

SUITABLE LUBRICANTS CONTAIN

NO WATER, HYDROCARBONS, OR

SILICON.

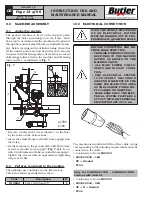

• Mount grippers (

Fig.

_

29 ref.

_

1

) on the external edge

of the rim in the highest point

.

THE GRIPPERS MUST BE TIGHTLY

SECURED TO THE EDGE OF THE

RIM.

• Move to work position

B

(

Fig.

_

6

).

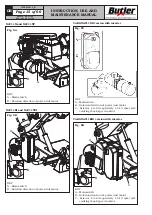

• Lower the mandrel arm completely. Roll the tyre on

the platform and hook it to clamp (

Fig.

_

30 ref.

_

1

).

• Lift the mandrel arm with the tyre hooked and turn

it counterclockwise by about 15-20 cm; the tyre

will position itself sideways with respect to the rim

Fig.

_

30

).

• Place the tool holder arm in “off-work” position

(

Fig.

_

15 ref.

_

1

); translate it to the inner side of the

tyre and hook it again into work position (

Fig.

_

14

ref.

_

1

).

• Carry out the tools head 180° rotation until the hook

tool is moved onto the tyre side (see

Fig.

_

32

).

Fig.

_

32

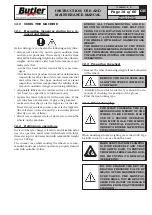

• Move to work position

D

(

Fig.

_

6

).

• Move the tool forward until the reference notch

matches the external edge of the rim coincide at about

5 mm from the rim itself.

• Move to work position

C

(

Fig.

_

6

).

• From the external side of the wheel, check the exact

position of the tool and, if necessary, correct it. Then,

turn the mandrel clockwise until the grippers reach

the lowest point (6 o’clock). The first bead should

now be inserted in the rim.

• Remove the grippers.

• Move to work position

D

(

Fig.

_

6

).

• Extract the tool from the tyre.

• Place the tool holder arm in “off-work” position

(

Fig.

_

15 ref.

_

1

); translate it to the outer side of the

tyre and hook it again into “work” position (

Fig.

_

14

ref.

_

1

).

• Carry out the tools head 180° rotation until the hook

tool is moved onto the tyre side (see

Fig.

_

21

).

7505-M001-3_B

NAV11N - NAV11NT

NAV11EI - NAV11TEI