INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 22 of 66

F.

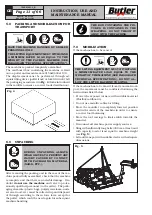

Turn the mandrel counterclockwise and, at the

same time, gradually move the tool carrier in-

wards to bead the tyre. Continue to turn the

mandrel while generously lubricating the tyre

rim and bead with a suitable lubricant. To avoid

risks, lubricate the beads by turning clockwise

if you are working on the outer side or counter-

clockwise if you are working on the inner side.

The more the wheel adheres to the rim, the slower

should the beading disc advance.

USE ONLY TYRE LUBRICANTS.

SUITABLE LUBRICANTS CONTAIN

NO WATER, HYDROCARBONS, OR

SILICON.

G.

Once external beading has been carried out, unhook

and lift the tool holder arm placing it in “off-work”

position (

Fig.

_

15 ref.

_

1

); use the handle control to

position the tool holder arm on the inner side of

the wheel, then place it in work position (

Fig.

_

14

ref.

_

1

) and secure it with the special coupling lever.

PAY ATTENTION WHEN REPOSI-

TIONING THE TOOL HOLDER ARM

TO AVOID CRUSHING HANDS.

H.

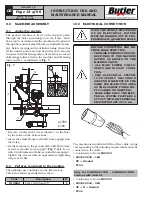

Carry out the tools holder head 180° rotation ac-

cording to the descriptions of the relevant para-

graph, so that the beading disc (

Fig.

_

19 ref.

_

1

) is

placed against the rim edge (

Fig.

_

19 ref.

_

2)

.

I.

Move to work position

D

(

Fig.

_

6

) and repeat the

operations described in points

E

,

F

until the tyre

has been completely beaded.

During all beading operations it is advisable to bend

the hook tool (

Fig

_

18

and

19 ref.

_

3

) to avoid obstacles

during the operating phases.

Fig.

_

19

2

1

3

7505-M001-3_B

NAV11N - NAV11NT

NAV11EI - NAV11TEI

12.6.2 Demounting

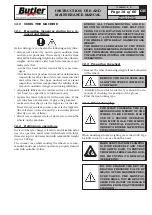

THROUGHOUT TYRE MOUNT-

ING/DEMOUNTING OPERATIONS,

CHECK THAT THE SELF-CEN-

TRING CHUCK CLAMPING PRES-

SURE IS CLOSE TO THE MAXIMUM

OPERATING VALUE (150 BAR).

Tubeless tyres can be removed in two ways:

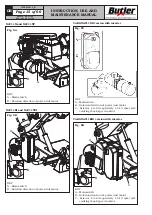

A.

If the wheel does not present particular problems,

continuing beading operation will completely dis-

lodge the beads from the rim. The inner bead,

pushed by the disc, presses against the outer one

till it has been completely removed (see

Fig.

_

20

).

Fig.

_

20

B.

If the wheel is especially hard, it is not possible to

carry out the procedure described in point

A

. A

different procedure will be necessary: use the hook

tool and follow this sequence of operations:

• Move to work position

C

(

Fig.

_

6

).

Only for NAV11N and NAV11EI

versions

• Position the tool holder arm on the outer side of the

wheel and bring forward the hook tool, inserting it

between rim and bead until it is secured to the bead

itself (see

Fig.

_

21

).

Fig.

_

21