Page 18 of 41

GB

INSTRUCTION, USE AND

MAINTENANCE MANUAL

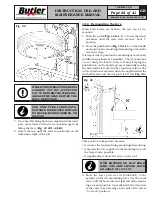

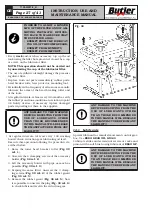

13.4 Wheel clamping

All wheels must be locked on the rubber plate (

Fig. 17

ref. 1

) through the central hole using the proper locking

device (

Fig. 17 ref. 2

).

Fig. 17

IN CASE OF USE OF RIMS WITH-

OUT CENTRAL HOLE, IT’S NECES-

SARY TO USE THE PROPER FIX-

TURE (AVAILABLE ON DEMAND).

To lock a rim proceed as follows:

1. Dowel the wheel (

Fig. 18 ref. 1

) on the locking

platform and check that the dragging pin (

Fig. 18

ref. 2

) enter in a hole placed on the rim hub.

Fig. 18

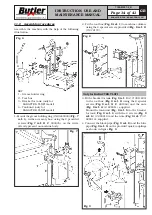

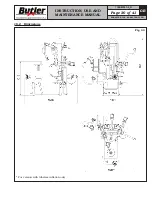

13.3 Mandrel height adjustment

The mandrel with central locking has 3 different height

modes, so that it is possible to operate with a wider

range of wheels. A “quick release” system allows to

remove the mandrel mobile part and to dowel the sup-

port plate at the required height.

In order to adjust the central support’s height, pull

the knob outwards (

Fig. 15 ref. 1

) and lift or lower

the central support’s plate up to the required height.

Now it’s possible to place the tyre in the right way with

the working tools.

When employing wheels with oversize off-set, use the

highest position.

With the standard wheels, the average height is nor-

mally used

Finally, the lowest height is indicated for reverse “drop-

center” wheels.

Fig. 15

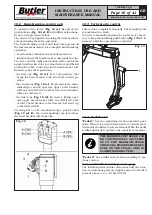

13.3.1 Reverse wheel pan protection

In case of use of reverse wheels, to protect the rim,

apply on the rubber platform a protection made of

a transparent plastic material available on demand

(

Fig. 16 ref. 1

). We suggest a constant replacement

of it and in any case if there are visible damages (see

Fig. 16

).

Fig. 16

1

KARACTER.TLX - KARACTER.TLXFI

7108-M007-0_B