Page 17 of 41

INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

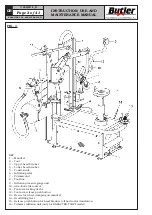

13.0 USING THE MACHINE

13.1 Precaution measures during tyre re-

moval and fitting

Before fitting a tyre, observe the following safety rules:

• rim and tyre must be clean, dry and in good condition;

if necessary, remove the balancing weights and clean

the rim. Check that:

- neither the bead nor the tread of the tyre are dam-

aged;

- the rim does not produce dents and/or deformation

(especially for alloy rims, dents can cause internal

micro-fractures, that pass unobserved at visual

inspection, and can compromise the solidity of the

rim and constitute danger even during inflation);

• adequately lubricate the contact surface of rim and

tyre bead, using specific tyre lubricants only;

• replace the inner tube valve with a new valve, if the

tyre tube has a metal valve, replace the grommet;

• make sure that the tyre is the right size for the rim;

on the contrary, never fit a tyre unless you are sure it

is the right size (the rated size of the rim and tyre is

usually printed directly on each of them);

• do not use compressed air or water jets to clean the

wheels on the machine.

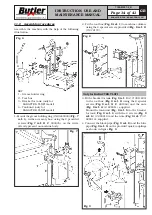

13.2 Preliminary operations - Preparing the

wheel

• Remove the wheel balancing weights from both sides

of the wheel.

REMOVE THE VALVE STEM AND

ALLOW THE TYRE TO COMPLETE-

LY DEFLATE.

• Establish from which side the tyre should be de-

mounted, checking the position of the groove.

• Find the rim locking type.

• Try to establish the special types of wheels, such as

“EH2” and “EH2+”, in order to improve locking, bead

breaking, assembly and disassembly performances.

W H E N H A N D L I N G W H E E L S

WEIGHING MORE THAN 10 KG

AND/OR WITH A FREQUENCY

OF MORE THAN 20/30 WHEELS

PER HOUR, A LIFTING DEVICE

SHOULD BE USED.

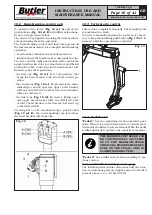

DO NOT CHANGE THE SET OP-

ERATING PRESSURE VALUE BY

MEANS OF THE MAXIMUM PRES-

SURE VALVES. THE MANUFAC-

TURER SHALL NOT BE RESPON-

SIBLE FOR INJURY OR DAMAGE

ARISING FROM UNAUTHORISED

CHANGES.

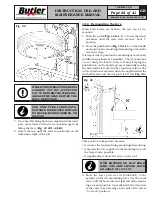

Version with tubeless inflation

The inflation pedal has two functions. The supply of

air at a controlled pressure as in the previous version,

and a second function of a jet of air from the inflation

nozzle to assist the beading in of the tyre.

DO NOT CHANGE THE SET OP-

ERATING PRESSURE VALUE BY

MEANS OF THE MAXIMUM PRES-

SURE VALVES. THE MANUFAC-

TURER SHALL NOT BE RESPON-

SIBLE FOR INJURY OR DAMAGE

ARISING FROM UNAUTHORISED

CHANGES.

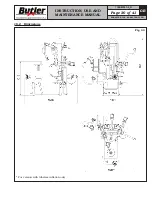

Fig. 14

KARACTER.TLX - KARACTER.TLXFI

7108-M007-0_B