22

ALL ONE-PIECE DOORS

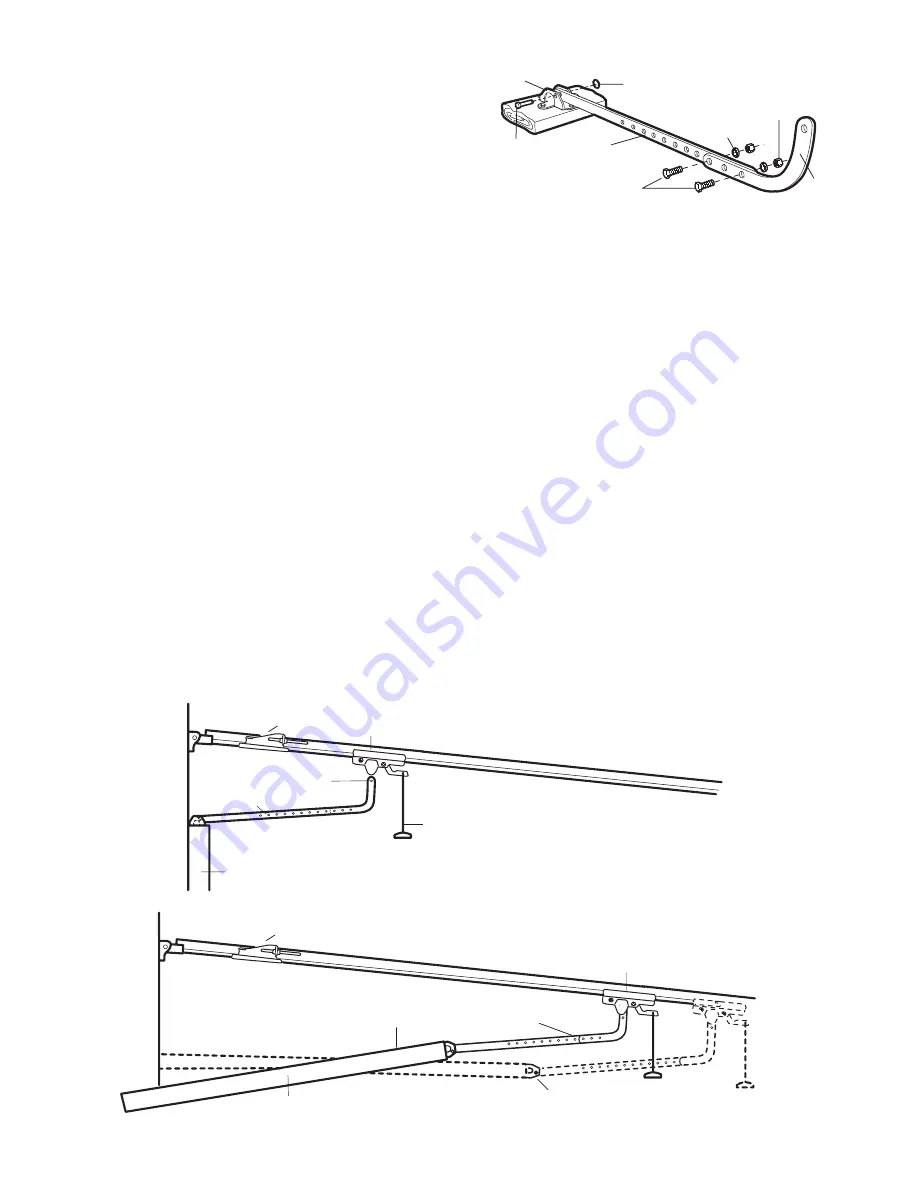

1. Assemble the door arm, Figure 4:

• Fasten the straight and curved door arm sections

together to the longest possible length (with a 2

or 3 hole overlap).

• With the door closed, connect the straight door

arm section to the door bracket with the

5/16"x1-1/4" clevis pin.

• Secure with a ring fastener.

2. Adjustment procedures, Figure 5:

• On one-piece doors, before connecting the door

arm to the trolley, the travel limits must be

adjusted. Limit adjustment screws are located on

the left side panel as shown on page 23. Follow

adjustment procedures below.

• Open door adjustment: decrease UP

travel limit

- Turn the UP limit adjustment screw

counter-clockwise 4 turns.

- Press the Door Control push button. The trolley

will travel to the fully open position.

- Manually raise the door to the open position

(parallel to the floor), and lift the door arm to the

trolley. The arm should touch the trolley just in

back of the door arm connector hole. Refer to

the fully open trolley/door arm positions in the

illustration. If the arm does not extend far

enough, adjust the limit further. One full turn

equals 2" (5 cm) of trolley travel.

• Closed door adjustment: decrease DOWN

travel limit

- Turn the DOWN limit adjustment screw

clockwise 4 complete turns.

Nuts

5/16"-18

Lock

Washers

5/16"

Ring

Fastener

Straight

Arm

Bolts

5/16"-18x7/8

Door

Bracket

Clevis Pin

5/16"x1-1/4"

Curved

Door Arm

- Press the Door Control push button. The trolley

will travel to the fully closed position.

- Manually close the door and lift the door arm to

the trolley. The arm should touch the trolley just

ahead of the door arm connector hole. Refer to

the fully closed trolley/door arm positions in the

illustration. If the arm is behind the connector

hole, adjust the limit further. One full turn equals

2" (5 cm) of trolley travel.

3. Connect the door arm to the trolley:

• Close the door and join the curved arm to the

connector hole in the trolley with the remaining

clevis pin. It may be necessary to lift the door

slightly to make the connection.

• Secure with a ring fastener.

• Run the opener through a complete travel cycle. If

the door has a slight "backward" slant in full open

position as shown in the illustration, decrease the

UP limit until the door is parallel to the floor.

NOTE:

When setting the up limit on the following

page, the door should not have a "backward" slant

when fully open as illustrated below. A slight

backward slant will cause unnecessary bucking

and/or jerking operation as the door is being opened

or closed from the fully open position.

Figure 4

Door Arm

Door Arm

Connector Hole

Closed

Door

Outer Trolley

Emergency Release Handle

Inner Trolley

Outer Trolley

Open Door

Door Arm

Correct Angle

Door with

Backward Slant (Incorrect)

Inner Trolley

Figure 5