10. The process chemicals will pollute the pump and pump oil when the pump is working.

Decontaminate the pump after maintenance if there is contamination as well as adopt

necessary precaution to protect personnel.

11. Ensure the stability of protective device before restart the pump.

6.2 The maintenance plan

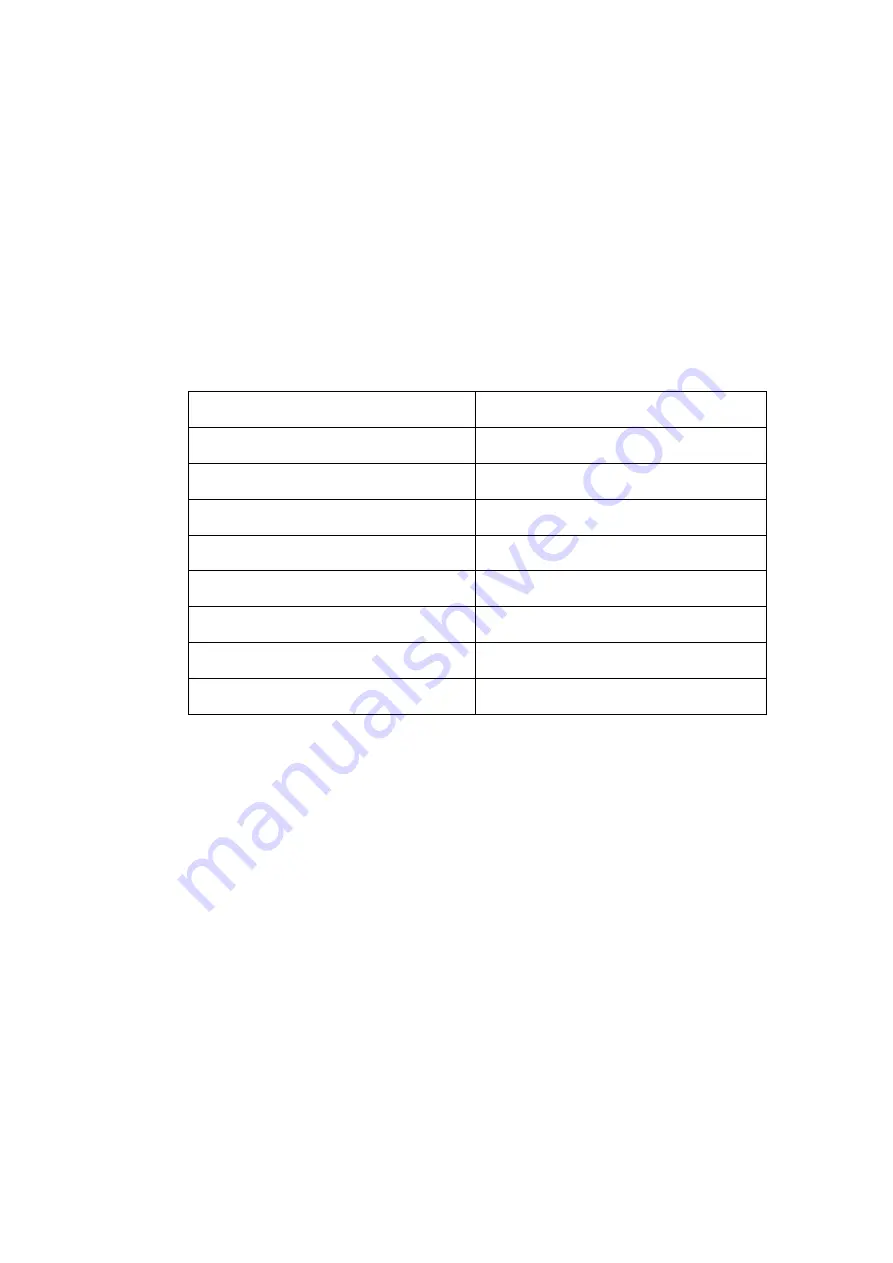

Table (2) shows the routine maintenance plan for the vacuum pump. If the vacuum pump

often inhale and exhaust corrosive gases or the gas ballasting controller connects with

atm. all the time, maintain the pump more often. Adjust the maintenance plan if

necessary.

Operation items

Period

Check oil level

Every week

Replace oil

Every 6 months

Replace gas ballast filter

Every 3000 hours

Check and clean air inlet filter

Every year

Clear the cover of motor

Every year

Clean and overhaul the pump

Every year

Test the motor

Every year

Replace the vanes

Every 3 years

Table 2 Maintenance plan

6.3 Check the oil level

1. Check the oil level regularly when the pump is running. Halt the pump before adding

oil.

2. Adding oil timely when the oil level is near or below the minimum oil level. Drain the

redundant oil if the oil level exceed the maximum level.

3. If the pump oil is contaminated and can

’t be cleaned, which affecting the performance

of the pump, replace the oil.

6.4 Replacement of the oil

1.

Start the pump for 10 minutes to preheat the oil (

Reduce the viscosity of the oil to

make it easy to flow out), then halt it.

2.

Cut off the power. Isolate the pump from the vacuum system.

3.

Remove

oiling plug screw

.

4.

Put a proper container under the drain port and remove the drain plug screw so that