19

fan speed and place desired speed tap wire on “HIGH” on

the interface board.

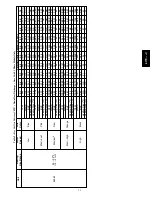

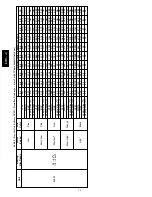

4. Refer to airflow tables (Table 8 or 9) to determine allowable

speeds for the dehumidification cooling fan speed. In Table

8 or 9, speeds that are not allowed for dehumidification

cooling are shaded.

5. Remove the vinyl cap off of the desired speed tap wire

(Refer to Table 6 for color coding) for the dehumidification

cooling fan speed and place desired speed tap wire on the

“LOW” connection on the interface board (IFB). Verify

that static pressure is in the acceptable range for the speed

tap to be used for dehumidification cooling.

6. Use any spare vinyl plugs to cap any unused speed tap

wires.

NOTE

: For heat pump operation, the recommended airflow is 350

to 450 CFM for each 12,000 Btuh of rated cooling capacity.

Continuous Fan Speed Set--up (Single Phase Models):

To change continuous fan speed:

1. Remove existing speed tap wire from the “FAN” terminal

on the IGC.

2. Connect the desired speed tap wire on the “FAN” terminal

on the IGC board.

Continuous Fan Operation (3--Phase Models)

When the DEHUM feature is not used, the continuous fan speed

will be the same as cooling fan speed. When the DEHUM feature

is used, the continuous fan will operate on IFB “LOW” speed

when the DH control lead is not energized, or IFB “HIGH” speed

when the DH lead is energized (see Fig. 14).

Table 6 – Color Coding for Indoor Fan Motor Leads

Black = High Speed

Orange = Med---High Speed

Red = Med Speed

Pink = Med---Low Speed

Blue = Low Speed

DH

DH

DH

DH

DH

DH

DH

DH

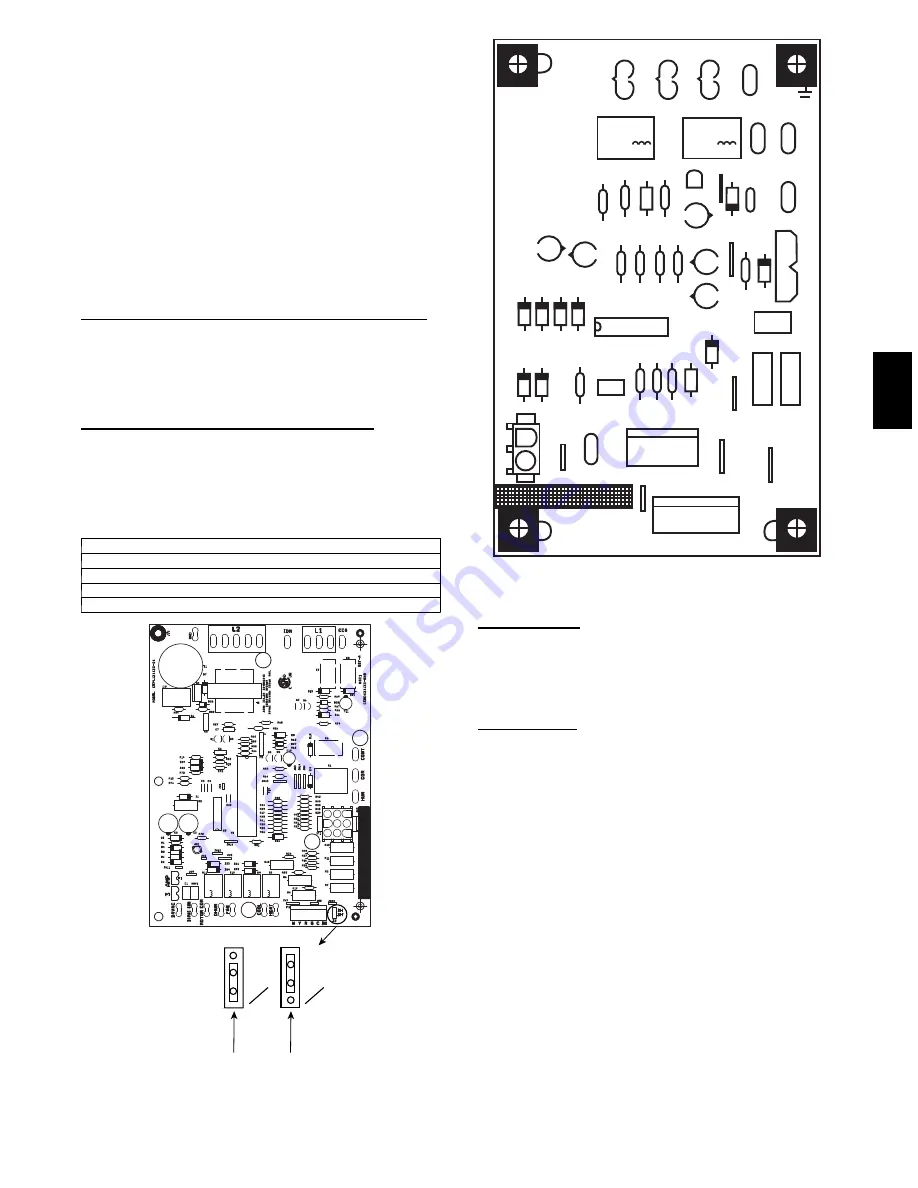

Shunt in no

dehumidification

position

Shunt in

dehumidification

position

A14399

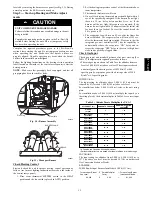

Fig. 13 -- Single Phase IGC Board

COM

LOW

HIGH

GAS

HEAT

Q1

R1L

C8

RL3

Q3

DCR

QCR

QC1

G1

G2

A7

D4

D6

C2

OILL

R9

AB A15

C4

C9

C0

R4

RL4

C7

R2

R3

R5 R6

QCB

Y

Y

R

U

C 24VAC

JW1

P2

P1

W2

Y2/

Y1/

Y

DH

G

C

R

SSTZ-8

P3

SDL

24V

AC/R

CDM/C

F1

QC6

QC7

QC4

QC3

K2

K1

D2

RI0

RI2

JM6

RI

DL

JM5

U1

C3

D3

D5

JW3

JW2

JW4

JW7

3 AMP

C

A09058

Fig. 14 -- Interface Fan Board (IFB)

Step 5 — Defrost Control

Defrost Control

The defrost control is used in all Puron (R--410A) heat pump

models. Its features include selectable defrost intervals of 30, 60,

90 minutes, and standard defrost speed up capability. This section

describes the sequence of operation and trouble shooting methods

for this control.

Defrost Sequence

The defrost control is a time/temperature control that has field

selectable settings of 30, 60, and 90 minutes. These represent the

amount of time that must pass after closure of the defrost

thermostat before the defrost sequence begins.

The defrost thermostat senses coil temperature throughout the

heating cycle. When the coil temperature reaches the defrost

thermostat setting, it will close, which energizes the DFT terminal

and begins the defrost timing sequence. When the DTF has been

energized for the selected time, the defrost cycle begins, and the

control shifts the reversing valve into cooling position, and turns

the outdoor fan off. This shifts hot gas flow into the outdoor coil

which melts the frost from the coil. The defrost cycle is terminated

when defrost thermostat opens, or automatically after 10 minutes.

677C

--

--

C

Содержание Legacy 677C**C Series

Страница 3: ...3 A150538 Fig 2 24 30 Unit Dimensions 677C C...

Страница 4: ...4 A150539 Fig 3 36 60 Unit Dimensions 677C C...

Страница 44: ...44 A150506 Fig 15 208 230 1 60 Connection Wiring Diagram 677C C...

Страница 45: ...45 A150516 Fig 15 Cont 208 230 1 60 Ladder Wiring Diagram 677C C...

Страница 46: ...46 A150507 Fig 16 208 230 3 60 Connection Wiring Diagram 677C C...

Страница 47: ...47 A150517 Fig 16 Cont 208 230 3 60 Ladder Wiring Diagram 677C C...