Understand the signal words DANGER, WARNING, and CAU-

TION. These words are used with the safety-alert symbol. DAN-

GER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies a hazard which

could result in personal injury or death. CAUTION is used to

identify unsafe practices which would result in minor personal

injury or product and property damage.

INTRODUCTION

The model 369RAN Furnaces are available in 2 sizes. Each size

unit is capable of 3 heat/airflow combinations by a simple nozzle

change. Unit 036105 covers inputs of 70,000, 91,000, and 105,000

Btuh, and unit 060120 covers inputs of 119,000, 140,000 and

154,000 Btuh. This eliminates the need to stock 6 separate units

This furnace is a multipoise unit. It may be installed in the upflow,

downflow or horizontal configuration.

The furnace is shipped as a packaged unit, complete with burner

and controls. It requires a line voltage (115 vac) connection to

control box, a thermostat hook-up as shown on wiring diagram, oil

line connection(s), adequate duct work, and connection to a

properly sized vent.

The air handling capacity of this furnace is designed for cooling

airflow. Refer to Table 12 for expected airflows at various external

duct static pressures.

LOCATION

I.

GENERAL

WARNING:

This furnace is not water tight and is not

designed for outdoor installation. This furnace shall be

installed in such a manner as to protect electrical com-

ponents from water. Outdoor installation would lead to a

hazardous electrical condition and to premature furnace

failure.

WARNING:

Do not use this furnace as a construction

heater. Use of this furnace as a construction heater

exposes furnace to abnormal conditions, contaminated

combustion air, and lack of air filters. Failure to follow

this warning can lead to premature furnace failure and/or

vent failure which could result in a fire hazard and/or

bodily harm.

Fig. 2—Dimensional Drawing

DIMENSIONS (IN.)

UNIT SIZE

A

B

C

D

E

F

G

H

J

K

L

036105

35

48-3/4

30-1/4

16-5/8

20

22

12

14

5

1-1/2

1-3/4

060120

39-1/2

53

32-1/4

18-3/4

24

28

12-9/32

16

6

1-5/8

1-1/2

A98037

3

″

19

″

20

″

20

″

19

″

2

″

PULL

OIL INLET

(BOTH SIDES)

VENT CONN

ELECTRICAL

CONNECTIONS

(BOTH SIDES)

.88 DIAM TYP

KNOCK-OUT BOTH SIDES

FOR J DIAM VENT

TOP KNOCK-OUT

FOR J DIAM VENT

A

E

G

B

L

H

C

D

F

K

—2—

Содержание 369RAN

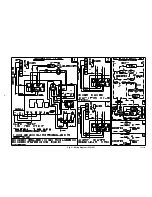

Страница 8: ...Fig 3 Wiring Diagram 036105 A00420 8...

Страница 9: ...Fig 4 Wiring Diagram 060120 A00419 9...