16

V-BELT TENSION ADJUSTMENT

• Slightly loosen motor mounting nuts.

• Adjust motor until the v-belt tension is correct.

• Tighten motor mounting nuts.

• Run motor for approximately 5 minutes. Stop motor, check belt tension, and readjust if necessary.

• Check that after tension adjustment and tightening the motor mounting nuts, both pulleys are in a straight

line to avoid excessive wear of the v-belt. Hold a straight edge against the compressor and motor pulleys as

shown. Edge must touch the pulleys at four points, or you must re-adjust motor.

COOLING SYSTEM

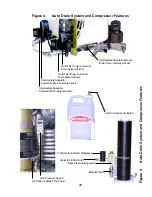

• The cylinders of the compressor block, the intermediate coolers, and the after-cooler are all air cooled.

• For this purpose, the compressor is equipped with a fanwheel connected to the counter-weight at the

crankshaft end opposite to the V-belt pulley. It draws the cooling air through the fanwheel cover from the

surroundings.

• Refer to page 6 for specific ambient temperature data.

CHECKING THE DRIVE BELT

The best tension for belt drive is the lowest possible, while not

slipping when under full load. This is best quantified by belt

depression with thumb pressure between the two pulleys, with

the belt deflecting ¼ “ (10mm) .

• Re-adjust v-belt after 25 hours of operation.

• Check the tension and adjust every 125 hours, assessing

the belt for wear or damage.

Содержание YP25DF

Страница 2: ...2 ...

Страница 30: ...30 Parts Drawing 1 Parts Drawing 1 ...

Страница 32: ...32 Parts Drawing 2 Parts Drawing 2 ...

Страница 35: ...35 Figure 5 Black Filter Tower Figure 5 Black Filter Tower ...

Страница 44: ...44 NOTES ...