SAW BLADES & DEPTH OF CUT

All of the saw blades currently designed for the Jointmaker Pro

contain between 350 and 460 teeth over their length. Because

the blade is inclined (the front of the blade is lower than the back

of the blade) in relation to the table surfaces, each tooth bears

the exact same workload.

For example, a piece of walnut with a 1/2” x 1/2” cross-section

can be cut in half with one stroke using the standard crosscut

blade. To correctly set the blade for this cut, you would adjust

the blade so that the first couple of teeth are below table height,

and the last tooth of the saw blade is set with the pitch adjustor

to approximately 1/32” above the stock of the wood. With the

stock held firmly against the fence, one stroke and the cut is

complete, smooth and accurate.

See the Cutting Guide page 20

for more details

.

This example is possible because the standard JM-P crosscut

blade has approximately 400 teeth. Using the stock and set-up

described above, each tooth of the saw has a chip load of just

over one one-thousandth of an inch (.5/400 = 0.00125”). It is

the combination of the chip load, precise linear movement and

blade rigidity that makes Jointmaker Pro cuts unparalleled in

quality or accuracy.

For wider stock (where more teeth are simultaneously engaged

with the stock), multiple passes are required utilizing a smaller

depth of cut per pass.

For example, 1/2” thick walnut 4” in width would dictate that you

set the saw up with the first couple of teeth below table height

(using the hand crank at the front of the JMP) and the last tooth

approximately 1/16” above the table (using the Pitch Adjustor).

With this set-up, it will take 8 passes to cut the stock in half. Be-

tween each pass the blade is raised approximately 1/16”. In this

situation, the 400 teeth are required to cut approximately 1/16th

of material per pass. The chip load is now one ten-thousandth

of an inch (.0625/400) per tooth! However, because the board is

4” in width, more teeth are engaged during each pass creating

more resistance. More resistance requires smaller bites for the

cuts to feel almost effortless.

The only “guide” we can provide for tailoring your technique to

accommodate the myriad of different species and sizes of wood

is to emphasize that the effort required to cut any wood should

be minimal. Harder material or wider stock requires smaller bites

and more passes. If you are overly aggressive, you will dramati-

cally shorten blade life and the quality of your cuts will suffer.

After a short “getting acquainted” period all of this will become

second nature.

As a reference, one full revolution of the crank handle raises the

blade exactly .055” or slightly less than 1/16”. You will discover

that extremely dense woods will require blade height adjust-

ments as small as 1/8 of a revolution between cuts and some

softwoods can be cut with 3 full revolutions for each pass! It is

your job to discover the optimal settings for ease of use accord-

ing to your own preferences and applications.

You will soon discover the general purpose cross-cut blade that

ships with the JM-P will do the majority of cuts (.4mm x 28). The

16 tooth rip blade is useful for cutting tenons and dovetails if you

have many to cut. The .3mm crosscut is ideal for small stock

but does not track well in deep cuts (it is so thin it will follow the

density changes of the wood being cut).

You will know when your blade is dull because of the resistance

you sense with cutting or the quality of the cut is not smooth

to the touch. Blades are not designed to be sharpened—they

are disposable. Replacement blades can be found at; www.

bridgecitytools.com or by calling 1-800-253-3332.

NOTE: Please visit www.bridgecitytools.com to view the Joint-

maker Pro videos!

THE FENCES AND HAND PLACEMENT

The Jointmaker Pro utilizes two fences that are normally bridged

by a sacrificial wooden fence. The only time you do not use both

tables is when you are cutting face miters.

There are two sacrificial fences, one is straight and the other

has an angled face. Use the straight fence for joinery and the

trap fence for crosscuts. We recommend the fences be locked

in the forward position for all cuts of 4” or less in width. For stock

wider than 4 inches, slide the fences to the back position.

When possible, your hands should be directly over the center of

the dovetailed ways on each side of the saw blade. As your ex-

perience with the saw grows, you will learn that you can use one

hand to make your strokes and the other will be raising the blade

on the return stroke. This combination is efficient and fast.

We recommend that your first cuts be made with both hands

employed during the sawing strokes.

NOTE: The table tops are orange for a reason; you can write on

them with a pencil. For example, once you have the fence set

to 90 degrees, you can scribe a pencil line along the fence and

use this line as a reference. Please visit our website to view the

video on how we set angles on the Jointmaker Pro.

STUPID MISTAKES WE HAVE MADE

We have ruined several blades because of human error. Please

review this section to learn from our mistakes.

•

MAKE SURE THE KEEL, THE FENCES, AND YOUR CLAMPS

are all TIGHT before sawing

. This will eliminate 80% of the

mistakes we have made.

•Lower the blade below table height after each session. Hori-

zontal surfaces attract things, and the blades are easily dam-

aged with contact by metal objects or heavy wood.

•It is helpful to have an old toothbrush nearby to periodically

clean wood fibers that may be embedded in the gullets of the

blade. This is particularly helpful when using the rip blade.

•Lastly, enjoy the fact that you are the motor. Let the saw do the

work and use as many passes as needed to accomplish your

tasks. WE GUARANTEE that aggressive sawing techniques are

going to be expensive for you.

2

Содержание Jointmaker Pro Signature Series

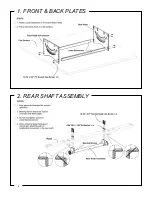

Страница 6: ...1 FRONT BACK PLATES 2 REAR SHAFT ASSEMBLY 5 ...

Страница 7: ...6 3 FRONT SHAFT TO KEEL 4 FRONT HEIGHT SHAFT TO SPINE ...

Страница 8: ...7 5 SAW SPINE TO KEEL 6 REAR HEIGHT SCREW TO KEEL ...

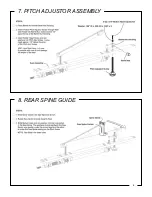

Страница 9: ...7 PITCH ADJUSTOR ASSEMBLY 8 REAR SPINE GUIDE 8 ...

Страница 10: ...9 PITCH ADJUSTOR SPINE GUIDE 9 10 FRONT SPINE GUIDE ...

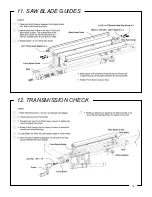

Страница 11: ...11 SAW BLADE GUIDES 12 TRANSMISSION CHECK 10 ...

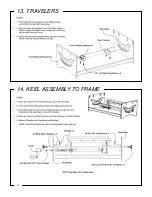

Страница 12: ...13 TRAVELERS 14 KEEL ASSEMBLY TO FRAME 11 ...

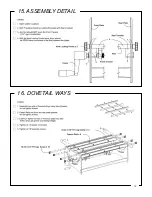

Страница 13: ...15 ASSEMBLY DETAIL 16 DOVETAIL WAYS 12 ...

Страница 14: ...17 INSIDE DOVETAIL SLIDERS 18 TABLE BUMPERS 13 ...

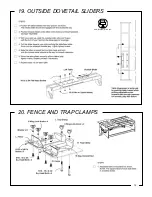

Страница 15: ...19 OUTSIDE DOVETAIL SLIDERS 20 FENCE AND TRAP CLAMPS 14 www BridgeCityTools com ...

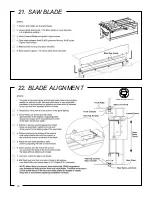

Страница 16: ...15 21 SAW BLADE 22 BLADE ALIGNMENT www BridgeCityTools com ...

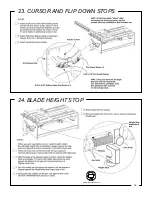

Страница 17: ...16 24 BLADE HEIGHT STOP 23 CURSOR AND FLIP DOWN STOPS www BridgeCityTools com ...

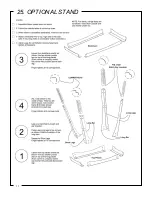

Страница 18: ...25 OPTIONAL STAND 17 ...

Страница 19: ...26 STAND CORNER KEY 18 ...

Страница 20: ...NOTES tm tm tm 27 LUBRICATION GUIDE 19 ...

Страница 21: ...N NOTES CUTTING GUIDE 20 ...

Страница 22: ...NOTES 21 ...