10

Maintenance

The Cold Pro Nitro™ System has very little maintenance requirements.

Changing the Air Filter

•

The air filter used with the Cold Pro Nitro™ System is a micro air-filter that filters

particles up to 0.1 μm (microns) with an efficiency of 99.9998%. According to DIN

EN 1822 this represents a U 15 filter class.

•

We recommend changing the filter module every 2 years.

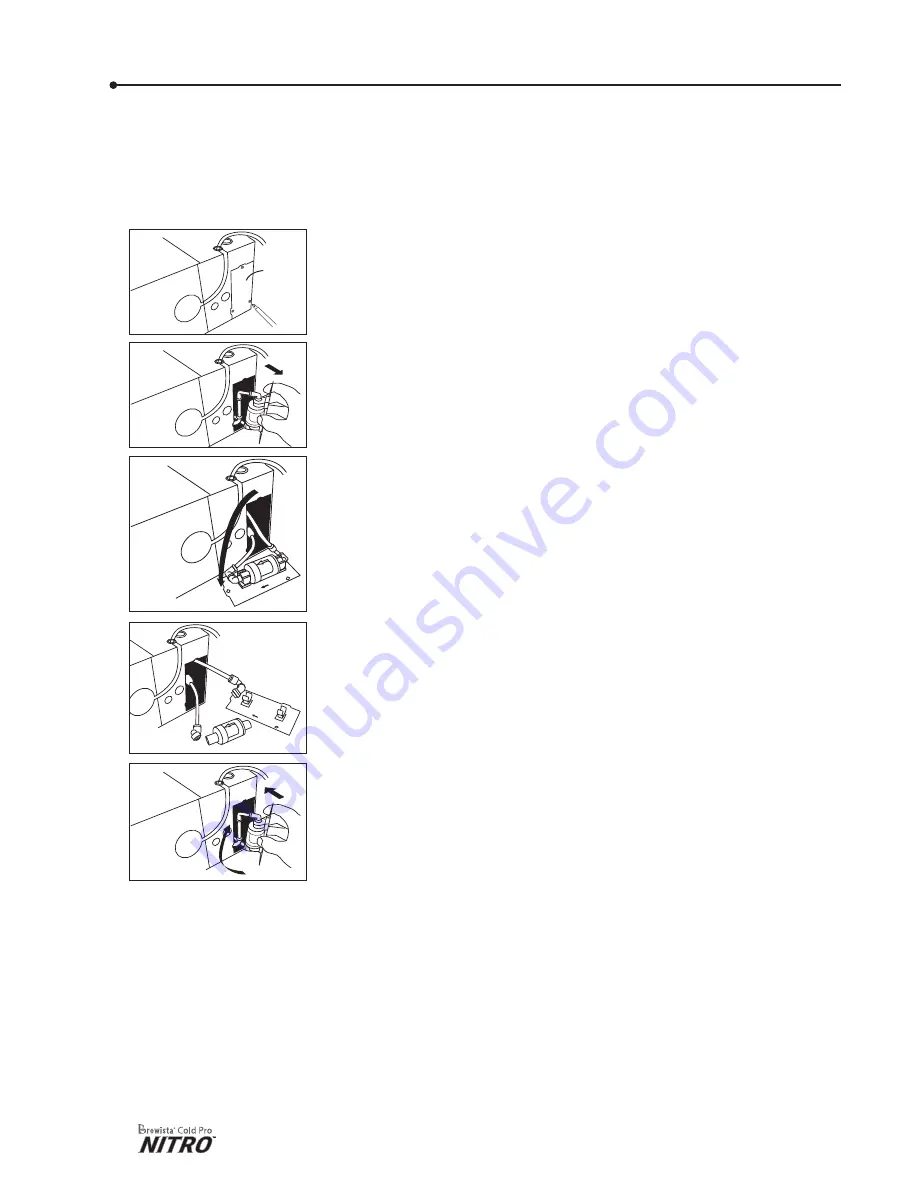

To change your system’s air filter:

1) Unplug the power cord from its wall outlet, open the tap on

your Cold Pro Nitro™ Machine, and release the pressure in

the lines. Turn the dispenser on its side.

2) Using a Phillips-head screwdriver, remove the screws from the

air filter cover and set aside in a safe place

3) Open the filter cover, pull it out, and turn it half way in a

counter-clockwise direction so that the panel lays on your

work surface. You now have access to the air filter module.

4) Click the module out of the clamps; unscrew the side adapters

and put the new module in.

5) Click the module in the clamps and insert the cover back while

making a half turn clockwise.

6) Close the cover and replace the 3 screws.

7) Return the dispenser to its upright position.

ALWAYS

place

the dispenser in an upright position before connecting the

power cable.

Air

Filter

Cover

Remove Dust at Condensator Grid

•

Blow away any dust particles that settle at the condensator grid on top of the

dispenser at least every 6 months or as needed. Dust particles on this grid can

reduce the machine’s cooling efficiency.

Changing O-rings and Connectors

•

If a Bag-In-Box connection system is used, O-rings or connectors may need to be

changed periodically. Frequency of changing these parts depends on the specific

system being used.

•

Brewista recommends checking these connections about once a month to ensure

proper system function.