13

CAUTION

Consider the filling medium for the pulsation damper housing

– in this case

compressed air

or

nitrogen

. If in doubt concerning the correct filling medium for

your pulsation damper, contact your Bredel representative for assistance.

CAUTION

Before pressurizing the pulsation damper ensure that the pulsation damper is built in

the piping system, ensure that the suction and discharge valves are op en, ensure

that any drain valves are closed. (process released for operation)

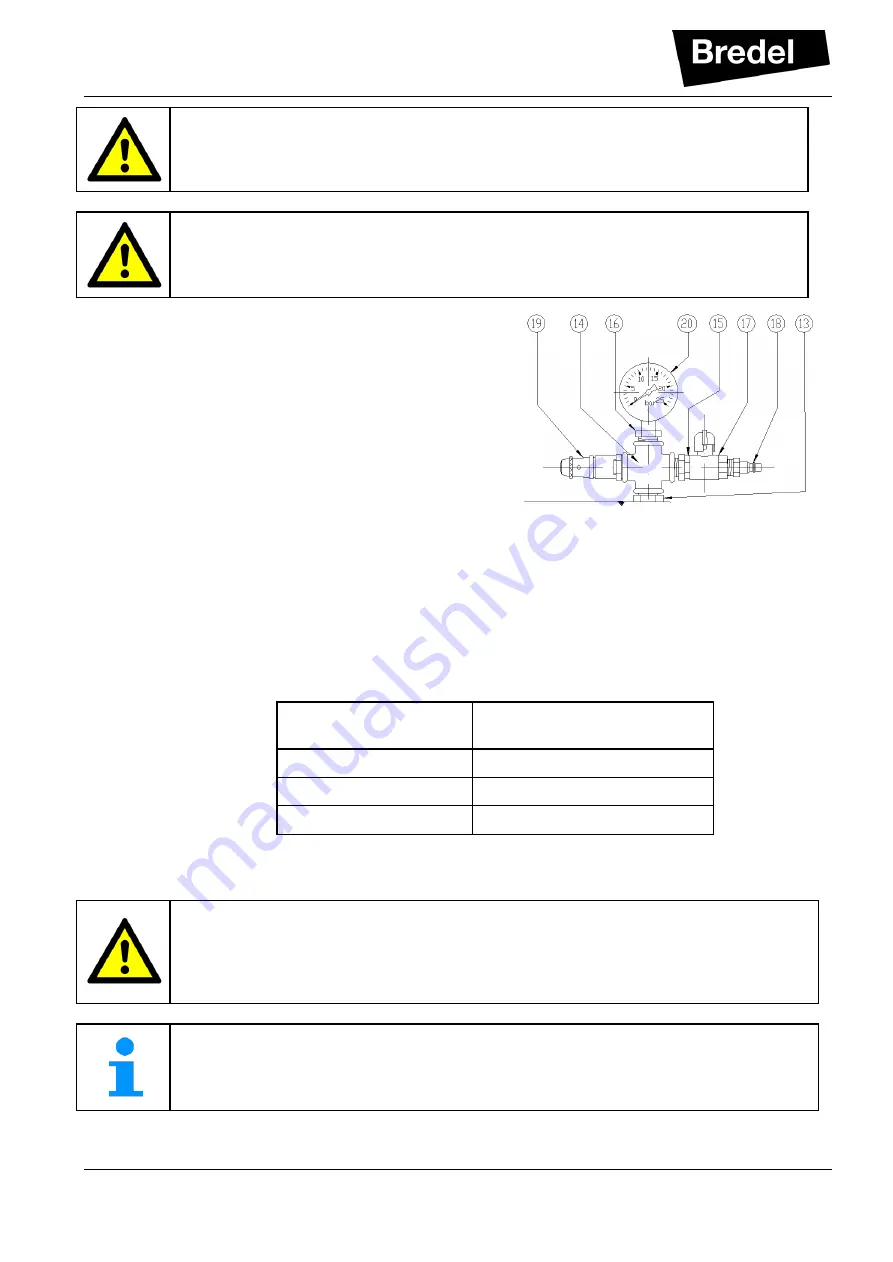

1. Shut the ball valve (pos. 17) on the pulsation

damper.

2. Connect the filling medium to the filling nipple (pos.

18).

3. Apply pressure to the pulsation damper by the filling

medium. Minimum filling medium supply pressure

should at least be equal to the process working

pressure directly upstream of the pulsation damper.

4. Start the pump

5. Open the ball valve (pos. 17) gently. Filling medium will now enter and pressurize the vessel.

Check the pressure gauge (pos. 20) for the actual gas pressure

p

v

inside the vessel.

6. Pressurize the vessel to approximately 80% of the actual fluid discharge pressure of the hose

pump (

p

2

), close to the pulsation damper.

7. Continue to fill the vessel with gas and closely watch the pressure pulsation on the manometer.

When the pulsation drops to a minimum the required gas pressure is reached. Shut off the ball

valve (pos. 17). The pressure inside the vessel should be within the indicated range shown in the

table below.

Vessel gas pressure

p

v

(reading gauge pos. 20)

PD size 40

p

2

<

p

v

<

p

2

+ 2 bar

PD size 65

p

2

<

p

v

<

p

2

+ 1,5 bar

PD size 100

p

2

<

p

v

<

p

2

+ 1 bar

The gas pressure

p

v

in the vessel must not exceed 16 bar.

8. Shut off the supply pressure of the filling medium

Caution

The optimum vessel pressure is process specific. It is advised to slowly increase the

vessel pressure until the pressure fluctuations downstream of the pulsation damper

are minimized and optimal damping is obtained. The gas pressure

p

v

must not exceed

the design pressure

p

s

of 16 bar.

If the actual process working pressure is very low (for example during standstill or after

a transfer cycle is completed) it is advised to relief the pre ssure from the pulsation

damper.