OPERATION

OPERATION

12

12

PROPER FUEL

THIS STOVE IS APPROVED FOR BURNING PELLETIZED WOOD FUEL ONLY!

Factory-approved pellets are those 1/4” or 5/16” in diam-

eter and not over 1” long. Sometimes, longer or thicker pellets bridge the auger

fl

ights, which prevents proper pellet feed. Burning wood in

forms other than pellets is not permitted. It will violate the building codes for which the stove has been approved and will void all warranties.

The design incorporates automatic feed of the pellet fuel into the

fi

re at a carefully prescribed rate. Any additional fuel introduced by hand will

not increase the heat output but may seriously impair the stove’s performance by generating considerable smoke. Do not burn wet pellets.

The stove’s performance depends heavily on the quality of your pellet fuel. Avoid pellet brands that display these characteristics.

a. Excess Fines

- “Fines” is a term describing crushed pellets or loose material that looks like sawdust or sand. Pellets can be screened

before being placed in hopper to remove most

fi

nes.

b. Binders

- Some pellets are produced with materials to hold them together, or “bing” them.

c. High Ash Content

- Poor quality pellets will often create smoke and dirty glass. They will create a need for more frequent maintenance.

You will have to empty the burnpot and vacuum the entire system more often. Poor quality pellets could damage the auger. Breckwell

cannot accept responsibility for damage due to poor quality pellets.

CAUTION: DO NOT USE CHEMICALS OR FLUIDS TO START THE FIRE.

CAUTION: DO NOT BURN GARBAGE OR FLAMMABLE FLUIDS SUCH AS GASOLINE, NAPHTHA OR ENGINE OIL.

Do not store fuel within installation clearances or within space required for charging and ash removal.

PRE-START-UP CHECK

Remove optional imitation log set, if in use. Remove burnpot, making sure it is clean and none of the air holes are plugged. Clean the

fi

rebox,

and then reinstall burnpot. Clean door glass, if necessary (a dry cloth or paper towel us usually suf

fi

cient). Never use abrasive cleaners on

the glass or door. Check fuel in the hopper and re

fi

ll if necessary.

NOTE:

The Big E hopper can hold up to 120 lbs. of pellets.

BUILDING A FIRE

Never use a grate or other means of supporting the fuel. Use only the Breckwell approved burnpot.

Hopper lid must be closed in order for the unit to feed pellets. If it is the

fi

rst time you have started the unit, or anytime the hopper has been

emptied of pellets, it will be necessary to prime the auger. In order to prime the auger, press and hold the fuel feed button after starting the

unit. Keep fuel feed button depressed until pellets begin to fall into the burnpot, then release the fuel feed button and allow the unit to operate

normally.

During the start-up period:

1) DO NOT

open the viewing door.

2) DO NOT

open the damper more than 1/4”.

3) DO NOT

add pellets to the burnpot by hand.

4) DO NOT

use the Fuel Feed button (unless you are priming the auger after running out of pellets). A dangerous condition could result.

NOTE:

During the

fi

rst few

fi

res, your stove will emit an odor as the high temperature paint cures or becomes seasoned to the metal. Maintain-

ing smaller

fi

res will minimize this. Avoid placing items on stove top during this period because paint could be affected.

THE HOT ROD AUTOMATIC FIRESTARTER

a. Fill hopper and clean burnpot.

b. Press “On/Off” button. Make sure light is on.

c. The damper should be completely closed or open no more than 1/4” during start-up. This will vary depending on your installation and eleva-

tion. Once

fi

re is established, adjust for desired

fl

ame increasing the amount the damper is open as the heat setting is increased.

(See “

DAMPER CONTROL

”)

d. Adjust feed rate to desired setting by pressing “Heat Level Advance” button.

If

fi

re doesn’t start in 15 minutes, press “On/Off”, wait a few minutes, clear the burnpot, and start procedure again.

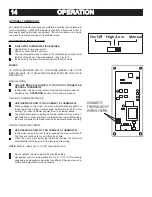

DAMPER CONTROL

The damper control rod on the stove’s lower left side adjusts the combustion air. This control is necessary due to the varied burn character-

istics of individual installations, different pellet brands and pellet feed rates. It allows you to improve the ef

fi

ciency of your stove. Providing

correct combustion air will reduce the frequency of cleaning your glass door and prevent the rapid buildup of creosote inside your stove and

chimney. You should adjust the damper based on the

fi

re’s appearance. A low, reddish, dirty

fi

re can be improved by pulling the damper out

slightly. A “blow torch”

fi

re can be improved by pushing the damper in a bit. Do not alter the damper for increased

fi

ring for any reason.

As a general rule, on lower feed rate settings, the damper should be in farther. On higher feed rates, the damper should be more open.

Through trial and error, you will

fi

nd the best setting. Consult your dealer if you need help.

NOTE:

On “1”, damper should be either completely closed or out approximately 1/8” to 1/4”. If damper is out too far, it can cause the

fi

re

to go out.

OPENING DOOR

If the door is opened while the stove is in operation, it must be closed within 30 seconds or the stove will shut down. If the stove shuts

down, push the “On/Off” button to re-start your stove.

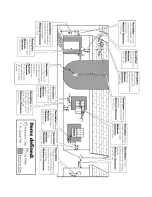

Содержание The Big E

Страница 25: ...ELECTRICAL DIAGRAM ELECTRICAL DIAGRAM 25 25 FIGURE 21 ...

Страница 27: ...27 27 ...