Page 44

Inspect eccentric shaft pins, bearing

mounting screw, washers and securement

hardware for wear or damage, positive

securement and proper operation

Inspect torque tube cams for securement,

wear or damage

Inspect housing cam brackets for secure-

ment, wear or damage

Inspect cylinder(s), hoses, fittings and

hydraulic connections for wear, damage or

leaks

Inspect power cable

Resecure, replace damaged parts, lubricate or cor-

rect as needed. See Carriage Ride Height Adjust

-

ment in Service Manual.

Resecure, replace or correct as needed.

Resecure, replace or correct as needed.

Tighten, repair or replace if needed.

Resecure, repair or replace if needed.

1500

Cycles

Maintenance and Lubrication Schedule

4500

Cycles

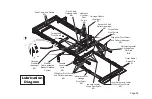

Hydraulic Fluid (Pump) - Check level.

Note: Fluid should be changed if there

is visible contamination. Inspect the

hydraulic system (cylinder, hoses, fittings,

seals, etc.) for leaks if fluid level is low.

Use BraunAbility 406416KS (1 qt) or 406417KS (1

qt -12 pack) Duragard

®

Hi-Tek Ultra HVI-26 hydraulic

fluid. Do not mix with other hydraulic fluids. Check oil

level with ramp fully deployed. Fill to maximum fluid

level indicated on reservoir. Do not overfill.

Perform all procedures listed in previous section also