Regarding the connection of the control units, provisions

such as strain reliefs, sufficient earth terminals and neutral

terminals should be present in the appliance or in external

connection boxes.

DIRECTIONS FOR THE INSTALLATION

−

For technical-safety reasons a regulation shutdown

must occur every 24 hours (systems for non-

permanent operation).

−

Automatic controls are safety devices and shall not be

opened.

Responsibility

and

guarantee

of

the

manufacturer is invalidated if the control is opened.

−

The control must be connected and disconnected only

with the supply disconnected.

−

The control can be mounted in any position.

−

Avoid exposure to dripping water.

−

Ventilation with the lowest temperature ensures the

longest life of the control.

−

Make sure that the type (code and times) you are using

is correct before installing or replacing the control.

ELECTRICAL INSTALLATION

−

The national and European applicable standards

(e.g.EN 60335/1prEN 50165) concerning electrical

safety must be respected.

−

Live

and

neutral

should be connected correctly, a

mistake could cause a dangerous situation, i.e. the

control and valves would still be live with the

thermostats and limits switched off. Besides, if

live-

neutral

polarity is not respected the control locks out

after TS.

−

Before starting check the cables carefully. Wrong

connections can damage the control and compromise

the safety.

−

The earth terminal of the control, the metal frame of the

burner and the earth on the mains supply must be well

connected.

−

Avoid putting the detection cable close to power or

ignition cables.

−

Use a heat resistant cable and detection probe, well

insulated to ground and protected from possible

moisture (or water in general).

In case of

live-neutral

network with unearthed

neutral

or

live-live

network (with center of the star not earthed) the

control can operate correctly by means of an inbuilt

resistor.

In the event of bad insulation between

live(s)

and earth the

voltage on the ionization probe can be reduced until it

causes the control to lock-out. In the presence of this kind

of network it is advisable to use our transformer type AR1

(booster).

CHECKING AT START

Always check the control before the first start and also

after amendments or a long period of no operation of the

system.

Before any ignition attempt make sure that the combustion

chamber is free from gas.

Then make sure that:

−

if the attempt to start occurs without gas supply the

control locks out after TS;

−

when stopping the gas flow (while the control is in

operational state) supply to the gas valve is interrupted

within 1 second and, after a recycling, the control

proceeds to lock-out (VM41);

−

when stopping the gas flow (while the control is in

operational state) supply to the gas valves is interrupted

within 1 second and the control proceeds to lock-out

(VM42);

−

operating times and sequence are suitable;

−

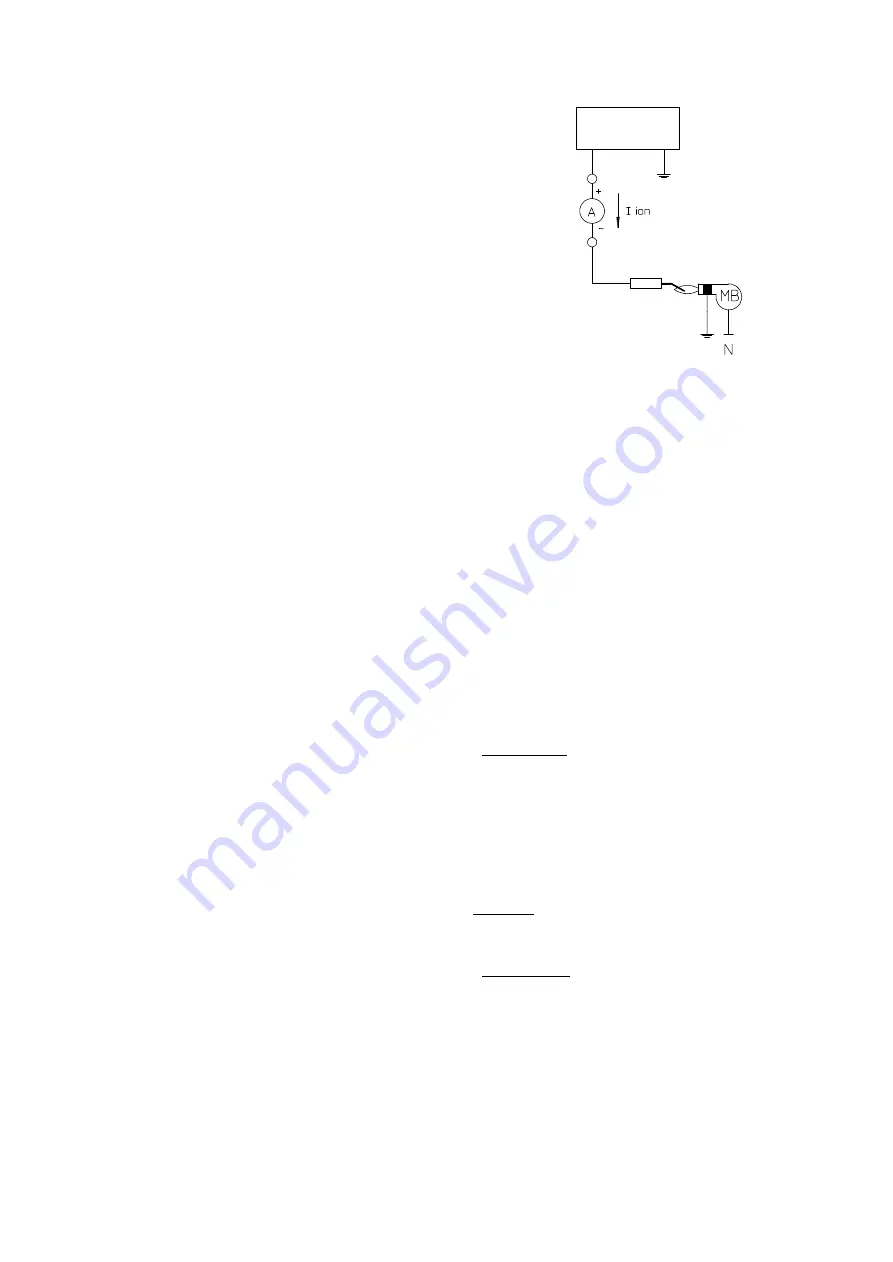

the level of the flame signal is sufficient, see Fig.3 to

execute the test;

−

the intervention of limiters or safety devices causes a

safety shut-down according to the application.

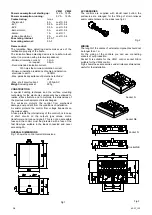

Fig.4

OPERATION

When the thermostats close, the control gives the starting

command to the burner motor and checks the position of

the air pressure switch contacts; only if the test is positive

with the air pressure switch in “air flow” state prepurge time

(TW) begins, at the end of which the gas valve is energized

and the ignition device is operated, thus starting the safety

time (TS).

If a flame is detected during the safety time the ignition

device is inhibited.

On the contrary, if the control does not detect a flame by

the end of TS, it proceeds to non-volatile lock-out, the gas

valve, the ignition device and the burner motor are

switched off while the lock-out signal output is supplied.

Model VM42 controls the opening of a second gas valve

15-20 seconds after the flame detection.

If a flame failure occurs in the running position the gas

valves are switched off and the VM41 proceeds to a

repetition of the ignition cycle, while the VM42 proceeds to

non-volatile lock-out.

The following diagrams are useful to understand the

operations of the controls.

Abnormal operation

- Air flow failure

VM41:

In case of failure of the air pressure switch or insufficient

air flow the control proceeds to lock-out with a delay of

about 15 seconds (t1 delay).

VM42:

In case of failure of the air pressure switch or insufficient

air flow in the running position the control proceeds to

lock-out with a delay of about 3 seconds. Air lack at start

causes a lock-out within about 8 seconds (t1 delay).

CAUTION: If for any reason the burner system is not

equipped with air pressure switch, terminals n.4 - 6 - 7

must be short-circuited.

- Parasitic flame

VM41:

The presence of a flame signal at start or during pre-

purge time causes lock-out within about 15 seconds (t2

delay).

VM42:

The presence of a flame signal at start causes a lock-out

within about 8 seconds. Parasitic flame during pre-purge

causes a lock-out within about 3 seconds (t2 delay).

RESET OF THE CONTROL

When the control has gone to lock-out a waiting time of 10

seconds should be allowed before attempting to reset the

control.

Control unit

8

Detection probe

4007_r00 3/4