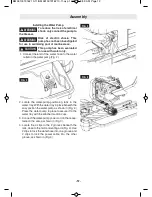

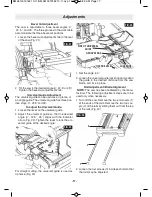

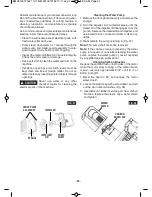

3. Use a slide caliper or straight ruler to measure the

distance between the two rails at one end of the

rails. Make sure that the distance is 12-5/8”

(320mm), and then slightly tighten the screw at

that end of each rail. Follow the same procedure

at the other ends of the rails to adjust the distance

between the rails to 12-5/8” (320mm), and slightly

tighten the screw at that end of each rail (Fig. 25).

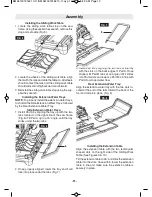

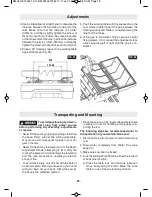

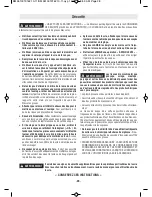

4. Place a 90° framing square on the working table

against the fence (Fig. 26).

5. Push the working table with the square along the

saw blade to determine if the gap between the

framing square and blade is consistent along the

length of the stroke.

6. If the gap is consistent, firmly secure all eight

fixing screws. If not, repeat the adjustment steps

above adjusting left or right until the gap is con-

sistent.

Adjustments

FIG. 25

FIG. 26

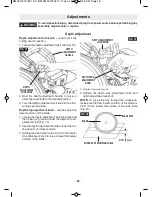

Transporting and Mounting

To avoid possible injury, discon-

nect plug from power source

before performing any assembly, adjustments

or repairs.

• Never lift the saw by gripping anything other than

the base. Parts, such as the sliding work table,

may move and cause sever injuries to your fin-

gers or hands.

• Never lift the saw by the power cord or the Depth

Adjustment Handle, attempting to lift or carry the

tool by the power cord will damage the insulation

and the wire connections, resulting in electric

shock or fire.

• To avoid back injury, only lift saw with the help of

a second person. Bend your knees so you can lift

with your legs, not your back. Lifting the saw by

the base is the preferred method.

• Place the saw on a firm, level surface where there

is plenty of room for handling and properly sup-

porting the tool.

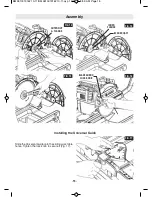

The following steps are recommended prior to

transportation of your wet tile/stone saw:

1. Disconnect plug from power source and wind up

cord.

2. Drain water completely from Water Tray (see

page 20.)

3. Make sure saw head is locked.

4. Lock the Sliding Work Table in either the forward

or back most position.

A. Press the table lock, and the work table can

move freely along the rails. Move the work

table to one of the two locking positions.

!

WARNING

-18-

320

223.38

BM 2610019162 10-11:BM 2610019162 10-11.qxp 10/20/11 8:59 AM Page 18