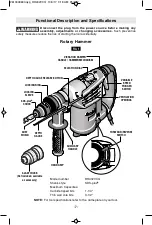

VARIABLE SPEED CONTROLLED

TRIGGER SWITCH

Your tool is equipped with a variable speed

trigger switch. The tool can be turned "ON" or

"OFF" by squeezing or releasing the trigger.

The speed can be adjusted from the minimum

to maximum nameplate RPM by the pressure

you apply to the trigger. Apply more pressure

to increase the speed and release pressure to

decrease speed (Fig. 1).

FORWARD/REVERSE SWITCH

The reversing switch is used to reverse rotation

of the bit (Fig. 1).

The reversing switch

should only be activated

when the motor is "OFF" and when bit is at a

complete standstill.

To use tool in "Forward" rotation move switch

torward the arrow that depicts forward.

"Reverse" the rotation of the bit move the

switch torward arrow that depicts reverse.

-10-

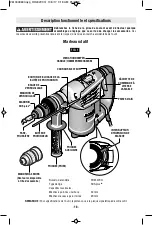

Drilling only: Drilling/hammering: Vario-lock Hammering only:

used for drilling

used for drilling allows for 12 desired used for light

wood, steel, etc. concrete positions of “hammer” chipping work

FIG. 10

Operating Instructions

SELECTOR DIAL

The selector dial allows the tool to be set for

various drilling/hammer drilling applications.

Rotate the selector dial right or left depending

on the below applications (Fig. 10).

When using demolition or chipping bits such as

bull points, chisels, spades, gouges, etc. the

“Hammer Only” mode must be selected.

Do not operate the

selection dial until the

tool come to a complete stop.

Shifting during

rotation of the chuck can cause damage to the

tool.

"VARIO-LOCK"- SELECTOR DIAL

The vario-lock can be set in any one of twelve

positions (30˚ increments). Choose a position

which is best suited for your operation. The

Vario-Lock position is intended for use with

chipping bits such as bull points, spades,

gouges, etc.

Rotate the selector dial, to the “vario-lock”

setting. Next, rotate the locking sleeve,

along with the accessory, to the desired

position. Then turn the selector dial to the

“hammer only” setting and slightly turn the

locking sleeve to have it automatically lock

into a definite position.

VIBRATION DAMPER HANDLE /

HAMMER MECHANISM

The integrated vibration damper in the main

handle and hammer mechanism reduces

vibrations (Fig. 1).

SLIP CLUTCH

The tool has a internal pre-set slip clutch.

The output spindle will stop rotating if the

accessory binds and overloads the tool.

TOOL TIPS

Following a few simple tips will reduce wear

on the tool and the chance of injury to the

operator.

The high efficiency available from the BOSCH

Rotary Hammer can only be obtained if sharp

and undamaged drilling tools are used. Note

that the costs for maintaining sharp drilling

tools are more than offset by the time lost in

operating dull drilling tools.

2610048693.qxp_RH432VCQ 10/4/17 9:18 AM Page 10