English |

25

Bosch Power Tools

2 609 006 763 | (17.1.13)

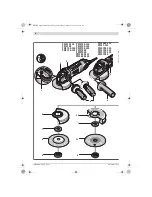

Switch on the machine

and place the front part

of the cutting guide on

the workpiece. Slide the

machine with moderate

feed, adapted to the ma-

terial to be worked.

For cutting expecially hard material, e. g., concrete with high

pebble content, the diamond cutting disc can overheat and

become damaged as a result. This is clearly indicated by cir-

cular sparking, rotating with the diamond cutting disc.

In this case, interrupt the cutting process and allow the dia-

mond cutting disc to cool by running the machine for a short

time at maximum speed with no load.

Noticeable decreasing work progress and circular sparking

are indications of a diamond cutting disc that has become

dull. Briefly cutting into abrasive material (e. g. lime-sand

brick) can resharpen the disc again.

Information on Structures

Slots in structural walls are subject to the Standard DIN 1053

Part 1, or country-specific regulations.

These regulations are to be observed under all circumstanc-

es. Before beginning work, consult the responsible structural

engineer, architect or the construction supervisor.

Maintenance and Service

Maintenance and Cleaning

Before any work on the machine itself, pull the mains

plug.

For safe and proper working, always keep the machine

and ventilation slots clean.

In extreme conditions, always use dust extraction as

far as possible. Blow out ventilation slots frequently

and install a residual current device (RCD).

When work-

ing metals, conductive dust can settle in the interior of the

power tool. The total insulation of the power tool can be im-

paired.

Please store and handle the accessory(-ies) carefully.

If the replacement of the supply cord is necessary, this has to

be done by Bosch or an authorized Bosch service agent in or-

der to avoid a safety hazard.

If the machine should fail despite the care taken in manufac-

turing and testing procedures, repair should be carried out by

an after-sales service centre for Bosch power tools.

In all correspondence and spare parts order, please always in-

clude the 10-digit article number given on the type plate of

the machine.

After-sales Service and Application Service

Our after-sales service responds to your questions concern-

ing maintenance and repair of your product as well as spare

parts. Exploded views and information on spare parts can al-

so be found under:

www.bosch-pt.com

Bosch’s application service team will gladly answer questions

concerning our products and their accessories.

Great Britain

Robert Bosch Ltd. (B.S.C.)

P.O. Box 98

Broadwater Park

North Orbital Road

Denham

Uxbridge

UB 9 5HJ

Tel. Service: (0844) 7360109

Fax: (0844) 7360146

E-Mail: [email protected]

Ireland

Origo Ltd.

Unit 23 Magna Drive

Magna Business Park

City West

Dublin 24

Tel. Service: (01) 4666700

Fax: (01) 4666888

Australia, New Zealand and Pacific Islands

Robert Bosch Australia Pty. Ltd.

Power Tools

Locked Bag 66

Clayton South VIC 3169

Customer Contact Center

Inside Australia:

Phone: (01300) 307044

Fax: (01300) 307045

Inside New Zealand:

Phone: (0800) 543353

Fax: (0800) 428570

Outside AU and NZ:

Phone: +61 3 95415555

www.bosch.com.au

Republic of South Africa

Customer service

Hotline: (011) 6519600

Gauteng – BSC Service Centre

35 Roper Street, New Centre

Johannesburg

Tel.: (011) 4939375

Fax: (011) 4930126

E-Mail: [email protected]

OBJ_BUCH-1824-001.book Page 25 Thursday, January 17, 2013 10:33 AM