24

| English

2 609 006 763 | (17.1.13)

Bosch Power Tools

Dust/Chip Extraction

Dusts from materials such as lead-containing coatings,

some wood types, minerals and metal can be harmful to

one’s health. Touching or breathing-in the dusts can cause

allergic reactions and/or lead to respiratory infections of

the user or bystanders.

Certain dusts, such as oak or beech dust, are considered

as carcinogenic, especially in connection with wood-treat-

ment additives (chromate, wood preservative). Materials

containing asbestos may only be worked by specialists.

– As far as possible, use a dust extraction system suita-

ble for the material.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the

materials to be worked.

Prevent dust accumulation at the workplace.

Dusts can

easily ignite.

Operation

Starting Operation

Observe correct mains voltage! The voltage of the pow-

er source must agree with the voltage specified on the

nameplate of the machine. Power tools marked with

230 V can also be operated with 220 V.

When operating the machine with power from mobile genera-

tors that do not have sufficient reserve capacity or are not

equipped with suitable voltage control with starting current

amplification, loss of performance or untypical behavior can

occur upon switching on.

Please observe the suitability of the power generator being

used, particularly with regard to the mains voltage and fre-

quency.

Switching On and Off

To

start

the power tool, push the On/Off switch

3

forwards.

To

lock

the On/Off switch

3

, press the On/Off switch

3

down

at the front until it latches.

To

switch off

the power tool, release the On/Off switch

3

or,

if it is locked, briefly push down the back of the On/Off switch

3

and then release it.

To save energy, only switch the power tool on when using it.

Check grinding tools before using. The grinding tool

must be mounted properly and be able to move freely.

Carry out a test run for at least one minute with no load.

Do not use damaged, out-of-centre or vibrating grind-

ing tools.

Damaged grinding tools can burst and cause in-

juries.

Working Advice

Exercise caution when cutting slots in structural walls;

see Section “Information on Structures”.

Clamp the workpiece if it does not remain stationary

due to its own weight.

Do not strain the machine so heavily that it comes to a

standstill.

After heavily straining the power tool, continue to run

it at no-load for several minutes to cool down the acces-

sory.

Do not touch grinding and cutting discs before they

have cooled down.

The discs can become very hot while

working.

Do not use the power tool with a cut-off stand.

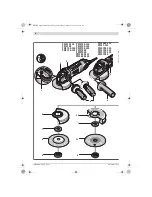

Rough Grinding

Never use a cutting disc for roughing.

The best roughing results are achieved when setting the ma-

chine at an angle of 30° to 40°. Move the machine back and

forth with moderate pressure. In this manner, the workpiece

will not become too hot, does not discolour and no grooves

are formed.

Flap Disc

With the flap disc (accessory), curved surfaces and profiles

can be worked.

Flap discs have a considerably higher service life, lower noise

levels and lower sanding temperatures than conventional

sanding sheets.

Cutting Metal

For cutting with bonded abrasives, always use the pro-

tection guard for cutting 10.

When cutting, work with moderate feed, adapted to the mate-

rial being cut. Do not exert pressure onto the cutting disc, tilt

or oscillate the machine.

Do not reduce the speed of running down cutting discs by ap-

plying sideward pressure.

The machine must al-

ways work in an up-

grinding motion. Other-

wise, the danger exists

of it being pushed

un-

controlled

out of the

cut.

When cutting profiles

and square bar, it is best

to start at the smallest

cross section.

Cutting Stone

Provide for sufficient dust extraction when cutting

stone.

Wear a dust respirator.

The machine may be used only for dry cutting/grinding.

For cutting stone, it is best to use a diamond cutting disc.

When using the cutting guide with dust extraction protection

guard

17

, the vacuum cleaner must be approved for vacuum-

ing masonry dust. Suitable vacuum cleaners are available

from Bosch.

OBJ_BUCH-1824-001.book Page 24 Thursday, January 17, 2013 10:33 AM