15

6 720 607 026

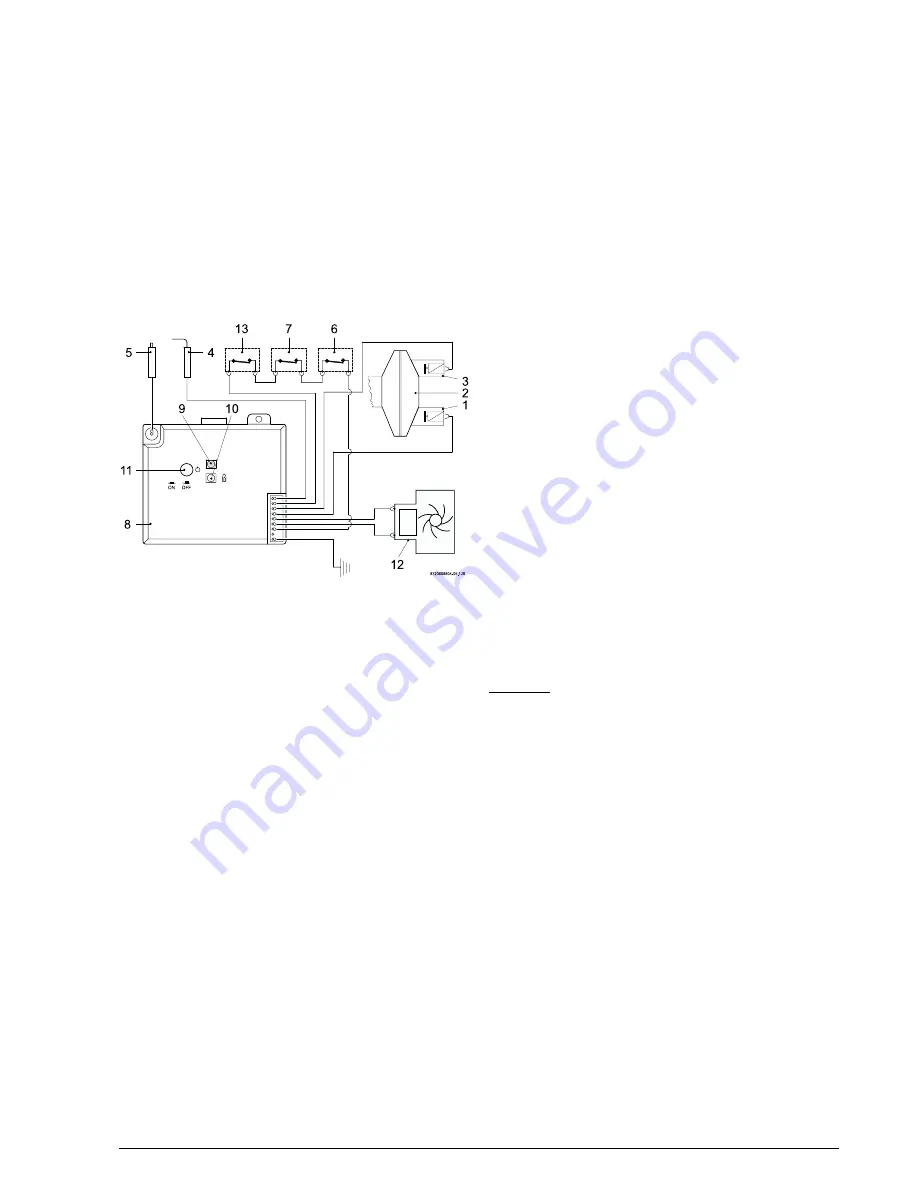

Fig. 13 - Electrical wiring diagram

5. Flue gas safety device tripped

Ventilate the room and operate the appliance 10 minutes

later. Provide more combustion air to the room and/or inspect

and correct venting system. Afterwards, if it happens again,

contact your service person.

WATER IS TOO HOT

1

.

Temperature Selection too high

Turn the temperature adjustment knob counter-clockwise

(to the left) to lower the maximum water temperature.

Note: This will increase the activation flow rate.

2. Inlet water temperature is too hot (as with solar

preheated water or high ground water temperatures)

Decrease gas pressure.

Note:

Only the model 125B LPS or

125B NGS should be used if the inlet water is preheated.

3. Ground water temperature is very warm

Reduce inlet gas supply to heater when inlet water

temperature is very warm (60-70 F). See also HOT WATER

TEMPERATURE FLUCTUATES / UNIT DEACTIVATED.

WATER IS NOT HOT ENOUGH

1. Temperature selection too low.

Change the setting. Turn the temperature adjustment knob

clockwise (to the right).

Note: This will decrease the activation flow rate.

2. Btu input is too low due to insufficient gas pressure

It is extremely important for a tankless instantaneous

water heater to have the right size gas line to obtain

the

correct

gas

pressure

See specifications on page 2. Unlike storage tank water

heaters, the burners of a tankless water heater must be very

powerful to heat water instantaneously since they do this

only at the time hot water is actually being used. It is therefore

imperative that the gas pressure requirement be met exactly.

Insufficient gas pressure will directly affect the water

temperature at the time of usage. See page 2 for correct

gas pressure settings and fig. 5 for locations where gas

pressures are taken.

3. Btu input is too low due to insufficient gas supply

Make sure your main gas line is fully opened. If using LP

gas, be sure that the size of the propane tank is adequate to

supply the required gas pressure.

4. Cold water is mixing with the hot water between the

425 HN and the outlet

Compare water temperature at outlet of the 425 HN (hold

the 425 HN outlet pipe with your hand) and at the tap. If

these two are very different, check for mixing valve or

plumbing crossover (see “NO SPARK AT THE PILOT”

paragraph #4).

5. Parts in water valve are dirty or damaged, which will

prevent the gas valve from being fully opened.

Water valve maintenance needs to be performed, see #6

under NO SPARK AT THE PILOT

PILOT LIGHTS BUT BURNERS WILL NOT COME ON

1. Confirm water valve assembly is working properly.

See Water Valve under

MAINTENANCE AND SERVICE

.

2. Confirm the flame sensor is in its proper position and

clean, lightly wipe clean if dirty.

See Fig. 10

3. Confirm the burner electrovalve switch is functioning

properly.

Measure milivoltage at burner electrovalve (see Fig. 13).

4. The Electronic Control Box (Fig. 13) may need to be

replaced.

Check wire connections and test operation of electronic

control box (see Fig. 13).

8

electronic control box

9

LED failure indicator

10

LED indicator main

burner operation

11

on/off switch

12

hydro-generator

13

flue gas safety device

1

burner electrovalve

2

gas control valve

3

pilot electrovalve

4

flame sensor

5

pilot electrode

6

overheat sensor

7

temperature limiter

MAIN BURNERS GO OUT DURING HOT WATER USE

1. Flow rate diminished below activation rate

Increase hot water flow rate.

2. Unbalanced pressure in the water lines

The added restriction caused by the 425 HN in the hot

water system can result in uneven pressures between the

cold and the hot. In such cases when mixing cold water at

the tap, the lower hot water pressure may be overpowered

by a much higher cold water pressure, which may cause the

425 HN burners to shut down. Make sure faucet aerators

and showerheads are free of minerals and dirt. Do not add

any flow restrictor to the shower head.

3. Minimum inlet pressure on well is inadequate

Check the inlet water pressure. On a private well, raise the

minimum pressure setting to 30 psi. Confirm that the

pressure tank is not water logged.

4. ECO (overheat sensor) tripped due to overheating

re-ignite the appliance 10 minutes later. If it happens again,

contact your service person.

Содержание GWH 425 HN

Страница 18: ...18 6 720 607 026 Fig 15 INTERIOR COMPONENTS DIAGRAM AND PARTS LIST ...

Страница 20: ...20 6 720 607 026 Fig 16 Flow chart of 425 HN ...

Страница 22: ...22 6 720 607 026 ...

Страница 23: ...23 6 720 607 026 ...