used for a preliminary estimation of vibration and noise

emissions.

The given vibration level and noise emission value represent

the main applications of the power tool. However, if the

power tool is used for other applications, with different ap-

plication tools or is poorly maintained, the vibration level

and noise emission value may differ. This may significantly

increase the vibration and noise emissions over the total

working period.

To estimate vibration and noise emissions accurately, the

times when the tool is switched off or when it is running but

not actually being used should also be taken into account.

This may significantly reduce vibration and noise emissions

over the total working period.

Implement additional safety measures to protect the oper-

ator from the effects of vibration, such as servicing the

power tool and application tools, keeping the hands warm,

and organising workflows correctly.

Fitting

u

Pull the plug out of the socket before carrying out any

work on the power tool.

Choosing the Planer Blade

The power tool can be fitted with different planer blades.

Fitting the adapter

(34)

(accessory) allows the power tool to

be changed from HSS planer blades

(15)

to HM/TC planer

blades

(20)

.

Always change both planer blades – replacing just one blade

will create an imbalance that could cause vibrations and

shorten the service life of the power tool.

Changing the HSS Planer Blades

u

Take care when changing the planer blade. Do not pick

up the planer blade by the cutting edges.

You may be

injured by the sharp cutting edges.

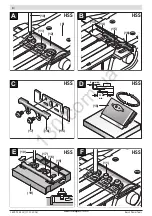

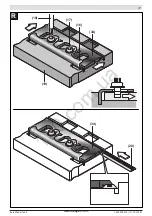

Removing the Planer Blades (see figures A–C)

– To replace the planer blades, turn the blade head

(13)

until the clamping jaw

(12)

is parallel with the planer base

plate

(8)

.

– Undo the three fastening screws

(11)

using the Torx key

(10)

and remove the clamping jaw

(12)

.

– Push the retaining clip

(16)

together with the planer

blade

(15)

out of the blade head

(13)

and/or the guide

groove

(14)

.

– Turn the blade head 180° and remove the second planer

blade.

Note:

Before changing or resharpening the planer blades,

remove the retaining clip

(16)

by undoing the fastening

screw

(17)

.

Resharpening HSS Planer Blades (see figure D)

Worn or blunt

HSS

planer blades can be resharpened using

the sharpening aid

(18)

(accessory) and a commercially

available grinding stone.

Place both planer blades in the sharpening aid and clamp

them firmly with the wing bolt. Make sure that both planer

blades are pushed in fully.

Move the planer blades placed in the sharpening aid steadily

across the grinding stone, applying light pressure.

Note:

The planer blades must not be resharpened by more

than 6 mm (i.e. to a minimum width of 23 mm). Both planer

blades must be replaced when they reach this size.

Fitting the Planer Blades (see figures E–F)

Before putting the new or resharpened planer blades (back)

in, clean the blade head

(13)

and, if necessary, the planer

blade

(15)

and the retaining clip

(16)

. If the planer blades

are very gummy, clean them with ethanol or petroleum.

Note:

New and resharpened planer blades must always be

set to the correct height before fitting.

The setting gauge

(19)

is used to set the height of the planer

blades. Place the planer blade

(15)

and the retaining clip

(16)

on the setting gauge. Make sure that the retaining clip

(16)

slots into the groove provided. Push the planer blade

(15)

against the guide and hold the retaining clip

(16)

in this

position with the fastening screw

(17)

. This will apply the

correct height setting automatically.

The planer blade must be fitted and aligned with the

centre

of the planer base plate

(8)

. Then tighten the three fasten-

ing screws

(11)

using the Torx key

(10)

, following the tight-

ening sequence (

①②③

) specified on the clamping jaw

(12)

.

Note:

Check that the fastening screws

(11)

are firmly

tightened before start-up. Turn the blade head

(13)

by hand

and ensure that the planer blades are not brushing against

anything.

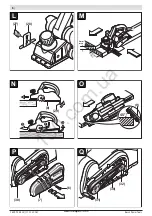

Changing the HM/TC Planer Blades

u

Take care when changing the planer blade. Do not pick

up the planer blade by the cutting edges.

You may be

injured by the sharp cutting edges.

Use only original Bosch HM/TC planer blades.

Hard metal (HM/TC) planer blades have two cutting edges

and can be turned. If both cutting edges become blunt, the

planer blades

(20)

need to be changed. HM/TC planer

blades must not be resharpened.

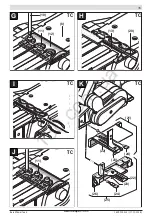

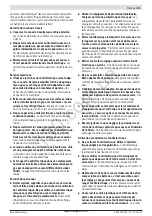

Removing the Planer Blades (see figures G–H)

– To turn or replace the planer blades, turn the blade head

(13)

until the clamping jaw

(12)

is parallel with the planer

base plate

(8)

.

– Undo the three fastening screws

(11)

using the Torx key

(10)

(approx. 1–2 turns). The clamping jaw

(12)

does

not need to be removed.

– Turn the blade head slightly and use a piece of wood to

push the planer blade

(20)

to the side and out of the

blade head

(13)

.

– Turn the blade head 180° and remove the second planer

blade.

English |

17

Bosch Power Tools

1 609 92A 4LE | (17.10.2018)

Автотовари

«130»

130.com.ua