EN

WWW.BORMANNTOOLS.COM

6

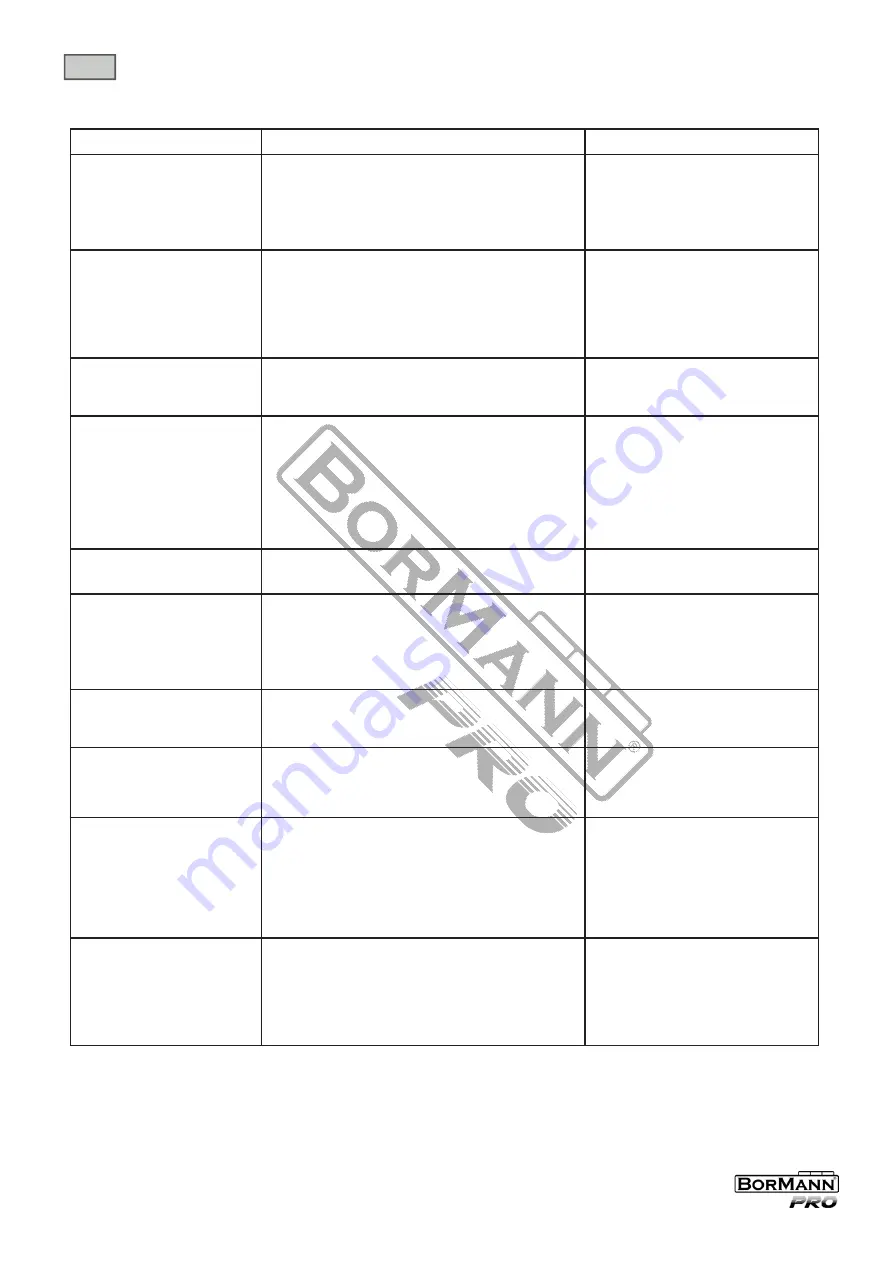

Τroubleshooting / Problems

Probable Cause

Remedy

Motor will not start.

1. Low Voltage.

2. Open circuit in motor or loose connections.

3. Blown fuse or breaker.

1. Check power source for proper voltage.

2. Inspect all lead connection on motor for loose or

open connections. (Send for Servicing.)

3. Short circuit. (Send for Servicing.)

4. Improper match between tool

and circuit, fuse or breaker

Motor will not start – fuses or circuit

breakers tripping or blowing.

1. Short circuit in line, cord or plug.

2. Short circuit in motor or loose connections.

3. Incorrect fuses or circuit breakers in power line.

1. Inspect cord or plug for damaged insulation and

shorted wires.

2. Inspect all connections on motor for loose or

shorted terminals and/or worn insulation.

3. Install correct fuses or circuit

breakers or switch tool to an appropriately sized

circuit.

Motor overheats.

1

. Motor overloaded.

2

. Extension cord too long and of insufficient gauge (weight).

1

. Reduce load on motor.

2

. Utilize an extension cord of appropriate gauge

and length or plug tool directly into outlet.

Motor stalls (resulting in blown fuses or

tripped circuit).

1. Short circuit in motor or loose connections.

2. Low voltage.

3. Incorrect fuses or circuit breakers in power line.

4. Motor overload.

1. Inspect connections on motor for loose or

shorted terminals or worn insulation. (Send for

Servicing.)

2. Correct low voltage conditions (for example:

improper extension cord length and/or gauge).

3. Install correct fuses or circuit breakers or plug

tool into an appropriate circuit, matched to an

appropriate fuse or breaker.

4. Reduce the load on the motor.

Machine slows when operating.

1. Feed rate too great.

1. Reduce the rate at which the workpiece is fed

into the working area of the tool (grinding wheel).

Wavy condition on surface of workpiece.

1. Machine vibrating.

2. Workpiece not being held firmly.

3. Wheel face uneven.

4. Wheel is too hard.

1. Ensure machine is securely mounted on a solid

surface.

2. Use a holding device to firmly retain the work

-

piece.

3. Dress the grinding wheel.

4. Use softer wheel, or reduce the feed rate.

Lines on surface of workpiece.

1. Impurity on surface of wheel.

2. Workpiece not being held tightly.

1. Dress the grinding wheel.

2. Use a holding device to more firmly retain the

workpiece.

Burning spots or cracks in the workpiece.

1

. Improper type of grinding wheel.

2

. Improper feed rate.

3

. Coolant required.

1

. Try wheels with softer bond or coarser grit.

2

. Slow down the rate at which the workpiece is fed

into the wheel.

3

. Introduce coolant.

Wheel dulls quickly, grit falls off.

1

. Feed rate is too aggressive.

2

. Wheel is soft.

3

. Wheel diameter too small.

4

. Bad wheel dressing.

5

. Defective wheel bonding.

1

. Decrease feed rate of workpiece into grinding

wheel.

2

. Select a grinding wheel with a harder bond of

material.

3

. Replace wheel.

4

. Dress the wheel.

5

. DO NOT USE – return wheel to point of pur

-

chase.

Wheel clogs and workpiece shows

burn marks.

1. Wheel is too hard.

2

. Feed rate is too slow.

3. Bad wheel dressing.

4. Coolant required.

1. Select a grinding wheel with a softer

bond of material.

2. Increase the feed rate of the workpiece

into the grinding wheel.

3. Dress the wheel.

4. Introduce coolant.