6

7

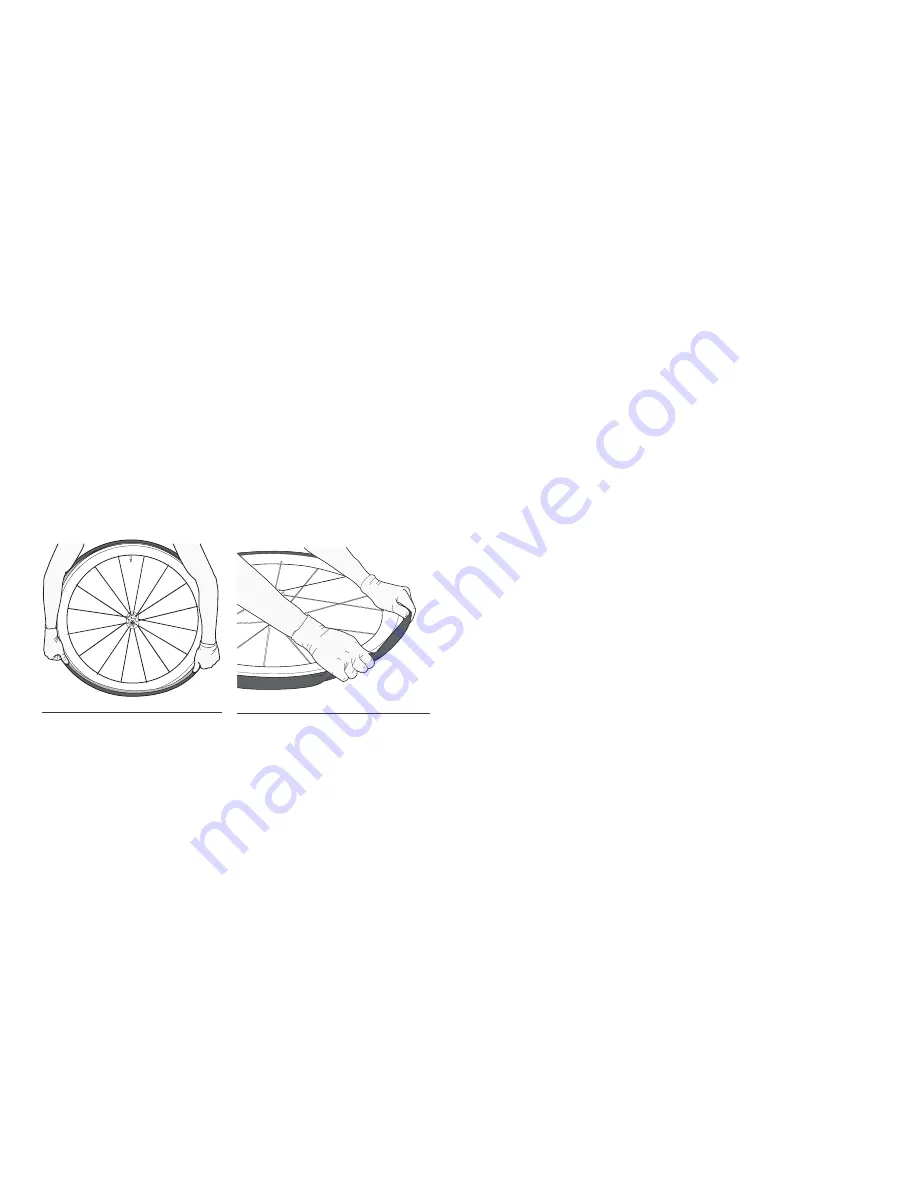

Figure 26.

Figure 27.

Completing the Tubular Installation

1. Inflate tires to the manufacturer’s maximum recommended pressure.

2. Check the rim for glue that might be on the braking surface or other areas. If it has, use

acetone and a clean rag to clean the rim.

3. Allow the glue to dry for roughly 24 hours.

4. After the glue is completely dry, test the mounting strength. With the tire deflated, roll the

tire slightly to check that the tire is adhered up to the edge of the tire well. Check the whole

way around the rim and on both sides. If the tire appears to have full adhesion it is ready for

inflation.

Note: You should occasionally check the adhesion of the tire to the rim to ensure the

glue is still holding.

7. Continue working down the tire, pressing it into rim until there are only a few inches of the

tire remaining outside the rim bead (Figure 26).

8. Pick up the wheel and slide the tire on the remaining few inches by pushing with your

thumbs (Figure 27).

9. Check the alignment of the valve stem. If it is not straight, slide the tire on the rim until it is.

10. Quickly center the tread over the rim. Place the wheel in the truing stand and look closely

at the alignment of the base tape in the rim. If the base tape is not centered over the rim,

move the tire sideways so that the base tape is equally exposed. Also chekc that the tread

runs straight.

11. Inflate the tire to slightly less than its recommended pressure and check the base tape

tread alignment again. This is the last time you’ll be able to move the tire around. When the

glue dries, you will not be able to move it around.

Содержание TUBULAR WHEEL - SETUP

Страница 1: ...Tubular Wheel Setup ENGLISH...