Page 14

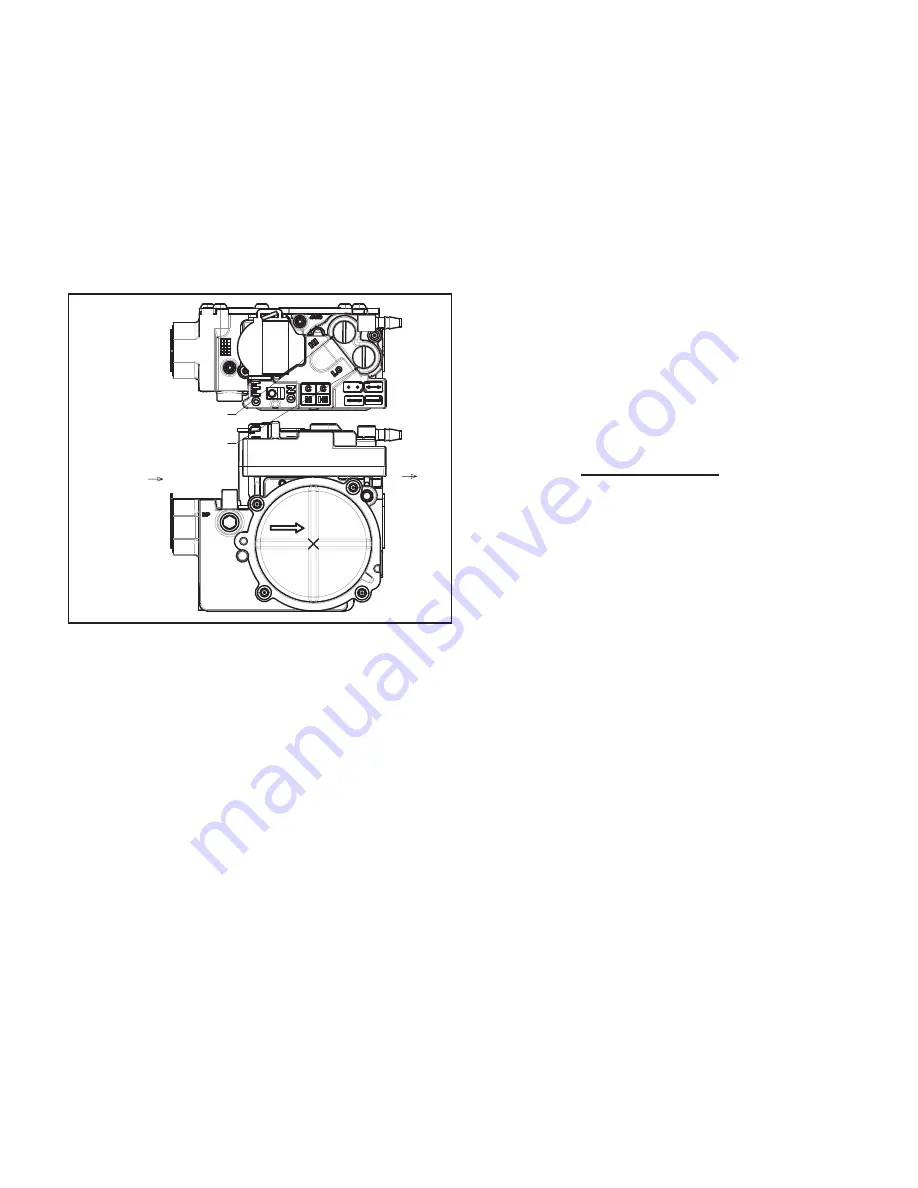

3. Slide the gas valve switch to the “ON” position (see

Figure 7).

4. Turn on electrical power to the unit.

5. Set the room thermostat to the desired temperature.

(If the thermostat “set” temperature is above room

temperature after the pre-purge time expires, main

burners will light.)

To Shut Down Main Burners

1.

Turn off electrical power to unit.

2. Slide the gas valve switch to the “OFF” position (see

Figure 7).

Figure 7. Gas Valve

Post-Start Check List

After the entire control circuit has been energized and the

heating section is operating, make the following checks:

1. Check for gas leaks, using soapy solution, in the unit

piping as well as the supply piping.

2. Check for correct manifold gas pressures (see Manifold

Gas Pressure Adjustment Regulator sections).

3. Check the supply gas pressure. It must be within the

limits shown on the rating plate. Supply pressure

should be checked with all gas appliances in the

building at full fire. At no time should the standby gas

pressure exceed 13” w.c., nor the operation pressure

drop below 5” w.c. for natural gas units or 11” w.c. for

propane gas. If gas pressure is outside these limits,

contact the gas supplier for corrective action.

4.

Adjust temperature rise to the range specified on the

rating plate.

Manifold Gas Pressure Adjustment Regulator –

Natural Gas

For purpose of input adjustment, the minimum permissible

gas supply pressure is 5” w.c. for natural gas.

Gas input must never exceed the input capacity shown on

the rating plate.

Units fueled by natural gas are rated for

manifold pressures of 2.0 inches W.C. for first stage

and 3.5 inches W.C. for second stage.

The manifold pressure can be measured by shutting off

the gas, removing the pipe plug in the downstream side

of the gas valve, and connecting a water manometer

or gauge.

Under no circumstances should the final

manifold pressure vary more than 0.3” w.c. from the

above specified pressures.

To adjust the regulator, turn

the adjusting screw on the regulator clockwise to increase

pressure and input or counterclockwise to decrease

pressure and input. See Figure 7 to assist in locating the

regulator on the gas valve.

Check the furnace rate by observing the gas meter, making

sure all other gas appliances are turned off. The test hand

on the meter should be timed for at least one revolution,

noting the number of seconds per revolution. The heating

value of the gas can be obtained from the local utility.

BTU/HR

Input

=

Cubic Feet per

Revolution

x 3600 x Heating

Value

# Seconds per

Revolution

Example

: By actual measurement, it takes 38 seconds for

the hand on the 1-cubic foot dial to make a revolution with

a 100,000 BTU/HR furnace running. The result is 99,750

BTU/HR, which is close to the 100,000 BTU/HR rating of

the furnace.

Manifold Gas Pressure Adjustment Regulator –

LP/Propane Gas

LP/propane units require a LPG regulator on both the gas

valve and on the LP/propane tank.

IMPORTANT

:

For purpose of input adjustment, the

minimum permissible gas supply pressure (inlet side of

gas valve) is 11” w.c. for LP/propane.

If at any time ignition is slow and burner does not seem to

be operating correctly, check manifold pressure (outlet side

of the gas valve).

It should be 10” to 10.5” w.c. pressure

for LP/propane.

Units fueled by LP/propane gas are rated for manifold

pressures of 5.6 inches W.C. for first stage and 10.0

inches

High Altitude

The input rate shown on the rating plate is for elevations

up to 2000 feet. For elevations from 2001 to 4500 feet,

the input rate is reduced by 5%. For elevations above

4500 feet, refer to the National Fuel Gas Code Z223.1

(latest edition) or the Canadian Installation Codes CAN/

CGA-B149.1 & B149.2 for further details.