Lit. No. B64092, Rev. 09

16

April 15, 2021

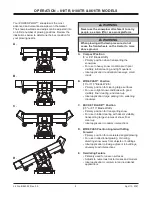

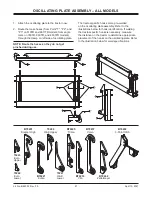

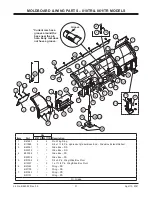

1. Position the front (top) hole in the A-frame with

the middle hole in the pivot beam. Insert cap

screw (

B61331

for 760TR;

50605

for 860TR

and 8600TR) through the top, and secure on the

bottom with washer (

B61203

) and nut (

B61008

).

2. Position the pivot beam and A-frame near the

mount locations at the rear of the blade. Position

the pivot beam between the two support ribs until

the connecting points on the beam align with

those on the snowplow.

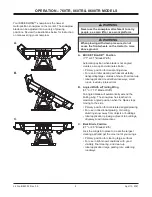

For 6760TR and 860TR models:

Insert one

bushing (

B16536

) through each mounting hole

and secure them with retaining rings (

B61616

).

Bushing

Retaining

Ring

Retaining

Ring

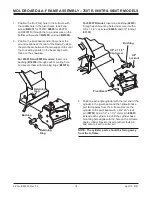

MOLDBOARD & A-FRAME ASSEMBLY – 760TR, 860TR & 8600TR MODELS

For 8600TR model:

Insert one bushing (

42410

)

through each mounting hole and secure it with a

3/8' x 1-1/2" cap screw (

66439

) and 3/8" locknut

(

91333

).

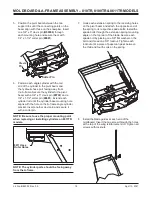

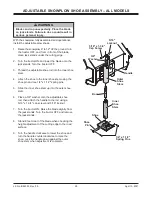

3. Position each angle cylinder with the rod end of the

cylinder in the pivot beam and the hydraulic hose

port facing away from the A-frame. Secure the

cylinder to the pivot beam with a 3/4" x 5" clevis

pin (

95739

) and a 1/4" x 1-1/2" cotter pin (

90601

).

Extend each cylinder rod until the cylinder base

mounting hole aligns with the hole on the A-frame

angle cylinder bracket. Insert another clevis pin

and secure it with a cotter pin.

NOTE: The cylinder ports should be facing away

from the A-frame.

Bushing

Pivot Beam

3/8" x 1-1/2"

Cap Screw

3/8"

Locknut

Содержание 760TR

Страница 2: ......