103-A00 page 8/12

MAINTENANCE

PUMP DISASSEMBLY

NOTICE:

Follow all hazard warnings and instructions provided in

the “Maintenance” section of this manual.

1. Drain and flush the pump and system as required.

2. Starting on the

inboard

(driven) end of the pump, clean

the pump shaft thoroughly, making sure the shaft is free of

nicks and burrs. This will prevent damage to the lip seal

when the inboard head assembly is removed.

3. Remove the shaft key(35), and the packing follower stud

nuts (18). Slide the packing follower (75) from the shaft.

A slight pry with a screwdriver may be necessary.

4. Pull the packing rings (19) from the stuffing box with the

use of a packing removal tool. Use care not to scratch or

damage the shaft. Discard packing. Remove the pack

washer (58) from the stuffing box.

Note:

If the pump is equipped with a commercial

mechanical seal, refer to the seal manufacturer’s

instructions for removal.

5. Remove the inboard head capscrews (21) and pry the

head assembly away from the cylinder and off the shaft.

Remove head O-ring (72) and discard

6. The sleeve bearing (bushing) (24) is press fit into the head

and should not be removed unless replacement is

necessary. See step 1 of ‘Pump Assembly’.

7. Gently pull the rotor & shaft (13) out of the cylinder. While

one hand is pulling the shaft, the other should be cupped

underneath to prevent the vanes and push rods from

falling out.

8. From the opposite (outboard) side of the pump, remove

the bearing cover capscrews (28), bearing cover (27), and

bearing cover O-ring (26). Discard the O-ring.

9. Remove the outboard head (23) as instructed in steps 4

through 6 above.

PUMP ASSEMBLY

Before reassembling the pump, inspect all component

parts for wear or damage, and replace as required. Wash

out the bearing/seal recess of the head and remove any

burrs or nicks from the rotor and shaft.

1. Inspect the sleeve bearings (bushings) in both heads for

wear or damage and replace as required.

To replace the sleeve bearings (bushings):

a. Using an appropriately sized arbor press, remove the old

bearing from the head.

b. To aid installation and prevent bearing damage, heat the

head in an oven at 200

o

F (93

o

C) before installing the

bearing.

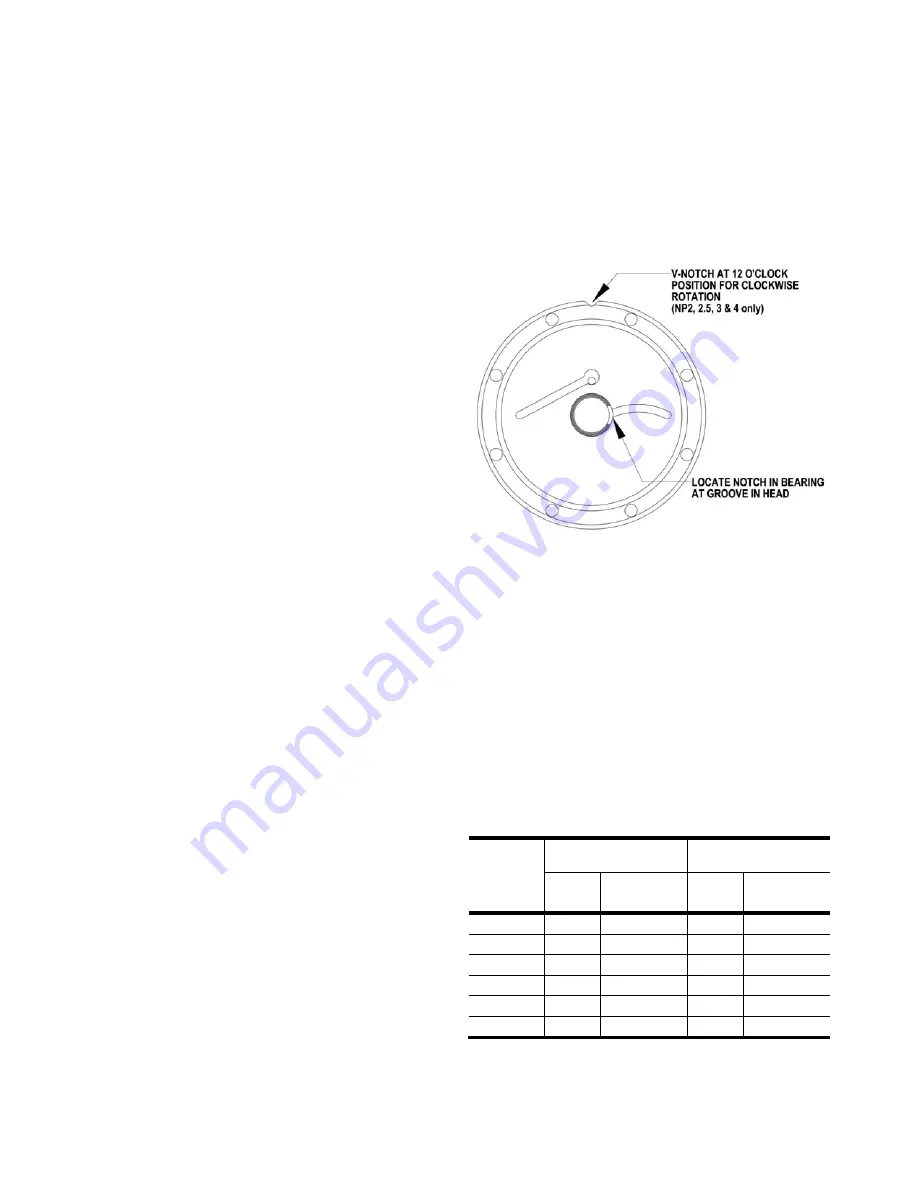

c. Coat the bearing with grease and place it on the inside

face of the head, with the notched end UP. Align the

notch in the bearing with the groove in the head (see

Figure 5).

d. Using an arbor press, press the bearing into the head in

one continuous motion, until it is flush with the inside face

of the head or slightly recessed (.015" maximum).

NOTE:

Ensure the bearing does not become misaligned during

the pressing motion. Starting and stopping the pressing

motion may result in a cracked bearing.

2. Reassemble the

OUTBOARD

side of the pump first:

For a CLOCKWISE rotation pump, position the pump

cylinder with the INTAKE port to the

left

.

For a COUNTERCLOCKWISE rotation pump,

position the pump cylinder with the INTAKE port to

the

right

.

3. Apply a small amount of quality O-ring lubricant on a new

head O-ring (72), and install in the groove on the inside

face of the outboard head (23).

Figure 5 – Bearing Location

4. For NP1.5: Place INTAKE marking on outboard head

towards INTAKE of pump.

NOTE

: V-notch location does

not apply to this model.

NP2, 2.5,3 AND 4: For clockwise (right-hand) rotation,

place the outboard head (23) on the cylinder with the V-

notch upward, in the 12 o'clock position. For

counterclockwise (left-hand) rotation, place the outboard

head (23) on the cylinder with the V-notch downward, in

the 6 o'clock position.

5. Install the head capscrews (21) and uniformly tighten;

torque per the Bolt Torque Table.

6. Install a new bearing cover O-ring (26) and attach the

bearing cover (27) to the outboard head. Install and

uniformly tighten the bearing cover capscrews (28);

torque per the Bolt Torque Table.

BOLT TORQUE TABLE

Model

Head

Capscrew

Bearing Cover

Capscrew

Size

Torque

ft-lb (Nm)

Size

Torque

ft-lb (Nm)

NP1.5

3/8"

25 (34)

5/16"

15 (20)

NP2

3/8"

25 (34)

3/8"

25 (34)

NP2.5

3/8"

25 (34)

3/8"

25 (34)

NP3

3/8"

25 (34)

3/8"

25 (34)

NP4

1/2"

58 (79)

5/8"

115 (156)

NPH4

1/2"

58 (79)

5/8"

115 (156)

7. Turn the pump around and begin assembly on the

opposite, inboard end.