Blackmer Page 109-A00 Page 3 of 4

INSTALLATION

NOTICE

This product must only be installed in systems which

have been designed by those qualified to engineer such

systems. The system must be in accordance with all

applicable regulations and safety codes and warn of any

hazards unique to the particular system.

ALIGNMENT ADJUSTMENT

To adjust the alignment of the gear reducer to the pump or

motor, use shims as needed.

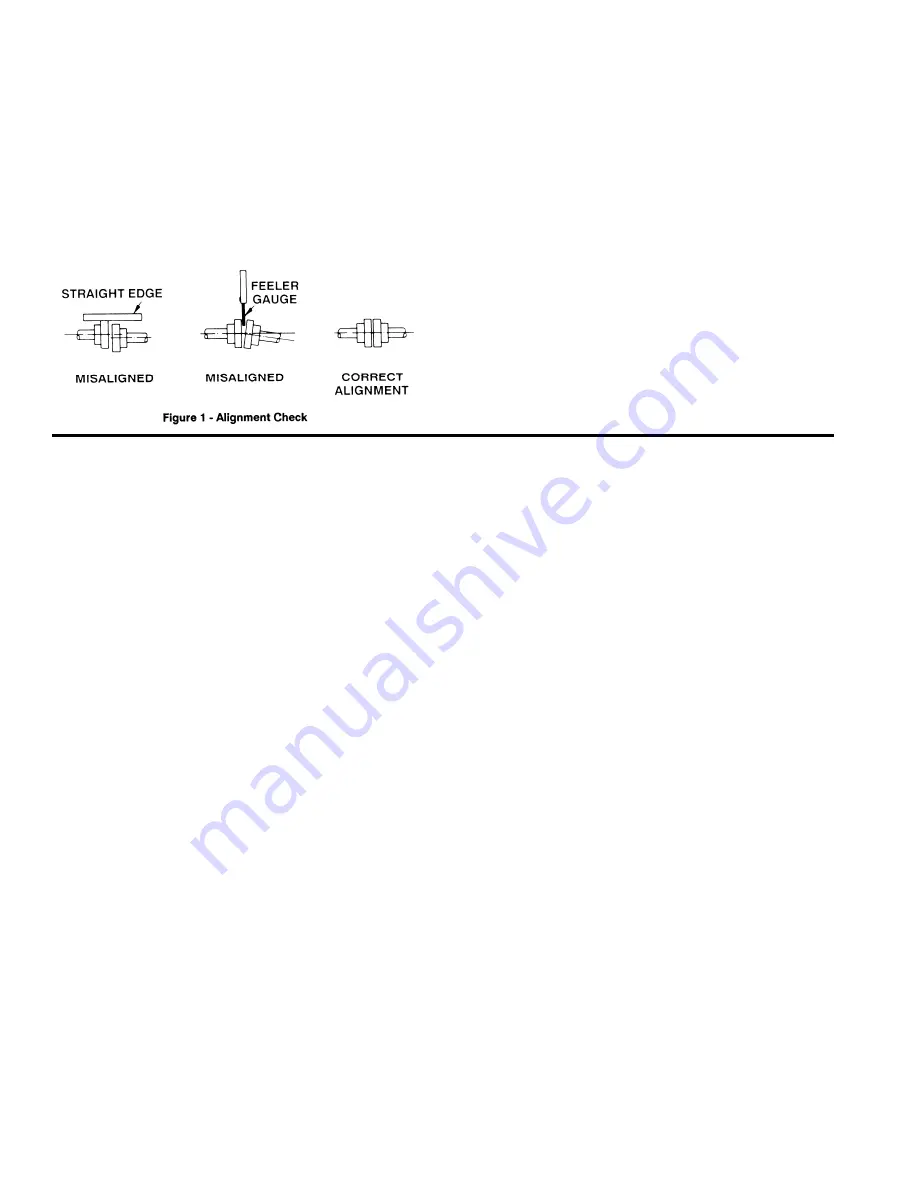

COUPLING ALIGNMENT

Both angular and parallel coupling alignment MUST be

maintained between the pump, gear, motor, etc. in

accordance with manufacturer’s instructions. Verify coupling

alignment after installation of new or rebuilt pumps. See fig. 1.

1. Parallel alignment: The use of a laser alignment tool or dial

indicator is preferred. If a laser alignment tool or dial indicator

is not available, use a straightedge. Turn both shafts by hand,

checking the reading through one complete revolution.

Maximum offset must be less than .005” (125 microns).

2. Angular alignment: Insert a feeler gauge between the

coupling halves. Check the spacing at 90º increments around

the coupling (four check points). Maximum variation must not

exceed .005” (125 microns). Some laser alignment tools will

check angular alignment as well.

3. Replace the coupling guards after setting alignment.

MAINTENANCE

NOTICE:

Maintenance and troubleshooting must be done by an

individual experienced with pump and reducer

maintenance and the type of system involved.

NOTICE:

To avoid possible entanglement in moving parts do not

lubricate pump bearings, gear reducer or any other parts

while the pump is running

.

CAUTION

: The normal full load operating temperature of the

gearcase is 180ºF (82ºC) – too hot to touch with the bare hand.

LUBRICATION

Gear reducers are not lubricated at the factory. Oil MUST

be added before starting the pump.

Horsepower calculations for Blackmer reducers are based on

75°F (24°C) ambient air temperature; 200°F (93°C) maximum

oil temperature using synthetic oil.

Blackmer recommends using synthetic oil with oxidation

inhibitors and is compatible with Buna elastomers. Use

synthetic oil AGMA Viscosity Grade 4 or ISO Viscosity Grade

150 such as Mobil SHC 629

, Mobil SHC 630

, Shell Omala S4

GX 150, Castrol Isolube EP 150 or equivalent.

To add oil to the gear reducer:

1. Remove the oil level plug (29D) and the fill and vent plug

(76C).

NOTE

: The vent fitting in the fill plug (76C) should

be kept clean to prevent expansion from forcing oil leaks at

the shaft.

2. Add oil through the filler hole until oil runs out of the oil level

hole – approximately 0.5 qt. (0.47 l) depending on the

orientation of the reducer mounting.

3. Replace the oil level plug and the fill and vent plug.

4. After the first two weeks of operation, the oil should be

drained, the gearcase flushed, and new oil added.

For normal operation, the oil should be changed every six

months or 1000 hours, whichever is shorter. If operation is

accompanied by frequent and wide changes in temperature,

or if the unit operates in an unusually moist or dusty

atmosphere, the oil should be changed every 500 hours or

every three months.

REDUCER DISASSEMBLY

The foot mounted gear reducer can usually be removed from

its unit assembly without disturbing the motor or pump

mounting.

1. Take apart the couplings and remove the capscrews in the

foot mount.

2. Once the couplings are apart and the capscrews are

removed, the reducer can be lifted away from the pump

and motor.

3. Remove the cover capscrews (112 & 112A). NOTE: The

gearcase cover is located on the gearcase with two (2)

dowel pins (38). These pins remain in the gearcase.

4. After the capscrews have been removed, insert a wedge

between the projecting lugs on the gearcase cover and tap

lightly until the cover loosens and can be removed from the

casing.

5. Remove the cover gasket (111).

6. The pinion & shaft (input shaft) (102) is a one-piece

assembly and does not come apart. If necessary, the

bearings (24 & 24A) can be removed from the shaft with

the use of a bearing puller or arbor press.

7. To remove the gear (101) and bearings (24B & 24C) from

the output shaft (125), use a gear puller or arbor press.

Support the assembly on the gear and press the shaft out

of the gear and bearings.