16

MAINTENANCE

NEVER Touch This Machine Without Training and Authorization By Your Supervisor.

USE ONLY GENUINE BIRO Parts and accessories Properly Installed.

PROMPTLY REPLACE Any Worn or Illegible Warning Labels.

ALWAYS Turn Off and Unplug Machine from Power Source and Perform Lockout/Tagout Procedure to This

Machine Before Cleaning or Servicing.

ROTATING GRINDING AUGER &

ROTATING MIXING PADDLE

TO AVOID SERIOUS PERSONAL INJURY

NEVER Place Hands Into Machine Input or Output Openings.

NEVER Bypass, Alter or Modify This Equipment in Any Way From Its Original Condition.

GENERAL:

Check all fasteners for tightness. Replace any missing fasteners.

Check all tags and labels. They must be legible. Replace if required.

Check casters. They must roll freely and lock in place. Replace if required.

Check lid alignment. It should sit evenly on top edge of hopper. Correct if required.

Open and close lid. There should be some resistance, lid should lower slowly.

Check removable hopper appearance. Fix any damage if required.

Check seal and seal retainer located on removable hopper. Correct if required.

Check mixing paddle for damage. Be sure it does not rub inside of hopper. Correct or replace if required.

Check bowl, auger, knife drive pin and ring for any damage. Replace if required.

Check control switches they must be in good working order. Replace if required.

Check pneumatic foot switch for damage. Fix or replace if required.

MOTOR GEAR DRIVES:

Both the mixer and grinder motor gear drives are totally enclosed. They are lubricated and sealed from the

manufacturer. They do not require any maintenance or lubrication changes.

ALWAYS Turn Off and Unplug Machine from Power Source and Perform Lockout/Tagout Procedure to This

Machine Before Cleaning or Servicing.

ALWAYS Use Qualified Technician and Electrician for Maintenance.

Check power cord for any damage. Repair or replace if required.

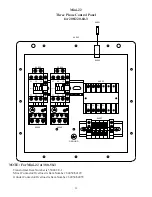

ELECTRICAL COMPONENTS:

Check all electrical connections for tightness.

If any access panels have been removed, they must be re-sealed with an NSF listed sealant.

Check all control switches for tightness.

Check lid limit switch for proper operation and tightness.

ELECTRICAL MAINTENANCE

Содержание MINI-22

Страница 2: ......

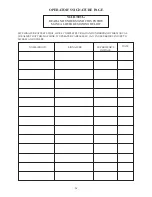

Страница 16: ...13 OPERATOR S NOTES ...

Страница 21: ...18 OPERATOR S NOTES ...

Страница 22: ...19 ...

Страница 23: ...20 ...

Страница 24: ...21 ...

Страница 26: ...OPERATOR S NOTES 23 ...