77-3049-R2.1 (12/2014)

12 / 20

EN

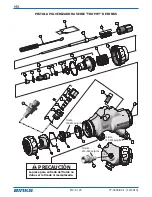

BINKS “TROPHY” SERIES AUTOMATIC SPRAY GUN

AIR CAP AND FLUID NOZZLE SELECTION CHARTS

CHART 13: ROUND SPRAY

AIR CAP AND FLUID NOZZLE SELECTION CHART

Air Cap

Air Cap

Part No.

Spray Pattern

Range

CFM

@

30 PSI

CFM

@

50 PSI

CFM

@

70 PSI

Fluid Nozzle

Typical Coatings

16

46-6505

2 – 4"

5.6

7.8

10.5

45-11050 series,

1.0 mm – 1.8 mm

Lacquers, Enamels

SETUP FOR SPRAYING

CONNECTING GUN TO MATERIAL HOSE

Gun should be connected by a suitable length of 3/8”

diameter material hose fitted with a connector with a

3/8” NPS(f) nut at gun end. 1/4” diameter hose is

recommended for use with low viscosity materials. (Fluid

hoses of different composition are available for special

fluids. See Binks hose catalog for hose selection.)

CONNECTING GUN TO ATOMIZING AIR

Gun should be connected by a suitable length of 5/16”

or 3/8” diameter air hose fitted with a connector and a

1/4” NPS(f) nut at gun end.

CONNECTING GUN TO CYLINDER AIR

Gun should be connected with 3/16” I.D. or 1/8” I.D. air

hose of shortest length possible with 1/4” NPS(f)

connector. Cylinder air must be connected to a 3-way

manual air valve or 3-way solenoid valve to operate

properly.

OPERATING THE BINKS “TROPHY” SERIES AUTOMATIC SPRAY GUN

CONTROLLING THE MATERIAL FLOW

When fed from a pressure supply, an increase in the

material pressure will increase the rate of flow. Correct

fluid nozzle size insures correct material flow rate. If

necessary, fluid flow can also be adjusted by adjusting

the amount of needle travel. This is done by adjusting

control knob (24) until the correct needle travel is

achieved.

ADJUSTING THE SPRAY PATTERN

The width of the spray pattern is controlled by the side

port control assembly (9). (See page 4). Turning this

control clockwise until it is closed will give a round spray,

turning it counterclockwise will widen the spray into a

fan shape. The fan spray can be turned anywhere

through 360° by positioning the air cap (5) relative to

the gun. To effect this, loosen air cap assembly, position

nozzle, then, re-tighten air cap assembly.

MAINTENANCE

LUBRICATION

Monthly: Remove piston assembly (17) and lubricate the

air cylinder chamber and needle valve spring with a

coating of Gunners Mate (35). Also, lubricate side port

control assembly (9) with oil.

!

CAUTION

Never use lubricants containing silicone since

these lubricants can cause finish defects.

Binks Gunners Mate (35) is recommended.

REMOVAL OF PISTON

To remove the piston, first unscrew the end cap (15),

remove two springs (16 & 23) and pull out the material

needle (22). Remove the piston by screwing needle

adjusting knob (24) into piston (21). See page 13 for

details.

TO REPLACE NEEDLE SEAL AND GLAND

ADAPTER IN FLUID INLET

See instructions on page 13.

Содержание TROPHY SERIES

Страница 19: ...77 3049 R2 1 12 2014 19 20 EN NOTES ...

Страница 39: ...77 3049 R2 1 12 2014 MX 19 20 MX NOTAS ...

Страница 59: ...77 3049 R2 1 12 2014 FR 19 20 FR REMARQUES ...